What Does NFPA 70E Mean To You?

Many electrical workers and engineers are familiar with the phrase “NFPA 70E,” but don’t have a good understanding of what the standard includes. The following Tailgate Topic is a summary of the standard and what it means to you as an electrical worker.

The first edition of NFPA 70E was developed in 1979; subsequent editions were published in 1981, 1983, 1988, 1995, 2000, 2004 and 2009. The standard addresses electrical safety requirements for employees during activities such as installation, operation, maintenance and demolition of electric conductors, electric equipment, and communications and signaling conductors and equipment, according to 70E-2009, 90.2(A).

What Does NFPA 70E Include?

NFPA 70E, titled “Standard for Electrical Safety in the Workplace,” is related to the National Electrical Code (NFPA standard 70) as follows:

•NFPA 70: National Electrical Code (NEC) describes how to design and install electrical systems, but not how to actually perform the work.

•NFPA 70E describes safe work practices for electrical construction and maintenance, but not how to design or install electrical systems.

•The two documents (NEC and NFPA 70E) have identical scopes and many of the same definitions. They both cover inside wiring in buildings and similar structures. Note: Neither standard covers utility (line) construction.

Since construction sites are workplaces, the NEC covers safety of electrical installations and NFPA 70E covers electrical safety in workplaces. While it technically applies to all workplaces (manufacturing facilities, hospitals, super stores, etc.), NFPA 70E is enforced most often on construction sites and at industrial plants. As a rule of thumb, anywhere that electrical construction and maintenance work happens is a workplace.

NFPA 70E Specifically Addresses Electrical Hazards

NFPA 70E describes how to protect electrical workers from three kinds of electrical hazards:

1. Electric shock and electrocution

2. Arc flash (electrical flame/fire)

3. Arc blast (high-energy electrical explosion)

The NFPA 70E standard only covers electrical hazards. Other construction hazards such as fall protection, ladder and scaffold use, and other construction safety compliance areas are covered by OSHA construction safety regulations (29 CFR 1926).

NFPA 70E Defines Two Strategies to Ensure Safe Electrical Work

NFPA 70E outlines two separate approaches for ensuring safe electrical work:

1. Turn off the power. Work de-energized, whenever possible.

•Live parts to which an employee might be exposed shall be put into an electrically safe work condition before an employee works on or near them.

2. Energized work can occur under special circumstances using special precautions. Power can remain on if the employer can demonstrate work on energized components can be justified, such as when:

•De-energizing introduces additional or increased hazards. Examples include interruption of life support equipment, deactivation of emergency alarm systems and shutdown of hazardous location ventilation equipment.

•De-energizing is infeasible due to equipment design or operational limitations. Examples include start-up or troubleshooting diagnostics and testing.

NFPA 70E requires the following when working on or near exposed live conductors and parts:

A. Plan the work. Have a written plan for performing the live work safely by utilizing an Energized Electrical Work Permit. Required information includes:

•Description of circuit and equipment to be worked on

•Justification for performing work in energized conditions

•Description of safe work practices

•Results of shock hazard and flash hazard analysis

•Shock and flash protection boundary

•Personal protective equipment

•Means to restrict access to unqualified persons

•Evidence of job briefing

•Work approval signatures

B. Shock and Flash Hazard Analysis

•Shock hazard analysis determines the voltage to which personnel will be exposed, boundary requirements and necessary PPE. Table 130.2(C) is used to determine boundary distances.

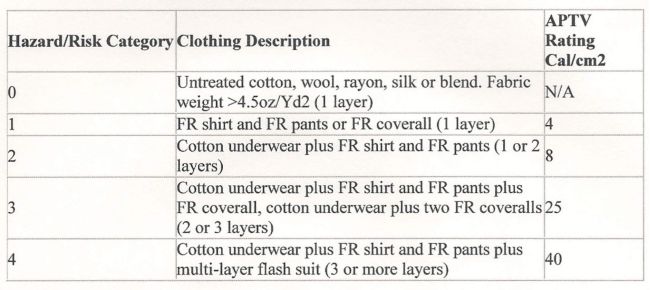

•Flash hazard analysis determines the flash protection boundary and PPE needed within that boundary. The flash protection boundary is determined by methods found in 130.3(A) or Annex D of the standard. Protective clothing is determined by using tables 130.7(C)(9)(a), 130.7(C)(10) and 130.7(C)(11).

C. Use Personal Protective Equipment (PPE)

•This includes flame-resistant (FR) clothing, insulated tools, face shields and flash suits.

•Each FR garment is assigned an ATPV rating by the manufacturer. The ATPV value represents the amount of incident energy that would cause the onset of second-degree burns. It also signifies the amount of protection the clothing affords when an electrical arc comes in contact with the fabric.

Table 130.7(C)(11) Protective Clothing Characteristics

In summary, NFPA 70E covers the full range of electrical safety issues, including safety-related work practices, maintenance, special equipment requirements and installation. It focuses on protecting people and identifies requirements that are considered necessary to provide a workplace that is free of electrical hazards. OSHA bases its electrical safety mandates, found in Subpart S part 1910 and Subpart K part 1926, on the comprehensive information found in NFPA 70E. NFPA 70E is recognized as the tool that illustrates how an employer might comply with these OSHA standards. The relationship between the OSHA regulations and NFPA 70E can be described as OSHA being the “shall” and NFPA 70E being the “how.”

About the Author: John Boyle is Corporate Director of Quality, Safety and Environment for Acciona Energy North America, a sustainable energy company that develops and operates wind and solar power facilities across North America. Boyle has more than 26 years of experience in nuclear generation and electric and gas distribution, which provides him with unique insight into the safety challenges faced by utility workers.

video