Days

:

Hours

:

Minutes

:

Seconds

iPi Monthly Forum for Utility Professionals

The iPi monthly forum is where you can get answers to questions you have from subject matter experts like David McPeak, Jim Vaughn, Danny Raines and other utility safety and ops professionals like yourself. Forums will include industry specific topics, challenges, trends, and solutions along with best practices in leadership, operations, and safety.

KNOWLEDGE, INSIGHT AND STRATEGY FOR UTILITY SAFETY & OPS PROFESSIONALS

Strategically layering moisture-wicking, flame-resistant garments can enhance worker comfort without compromising safety.

Layering flame-resistant (FR) clothing has long been a best practice among industrial athletes. In addition to providing critical hazard protection, this tried-and-true strategy enhances user comfort by enabling industrial athletes to add or remove clothing layers as their activity level or the weather changes. Base, middle and outer FR layers are equally important. Each serves […]

More News…

To expand our collective intelligence and better protect the workforce, we must treat all employee concerns as predictions of unwanted outcomes.

Overcoming Safety’s Blind Spot

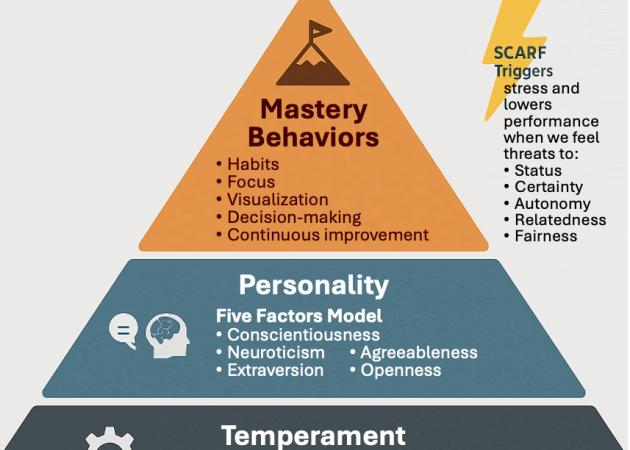

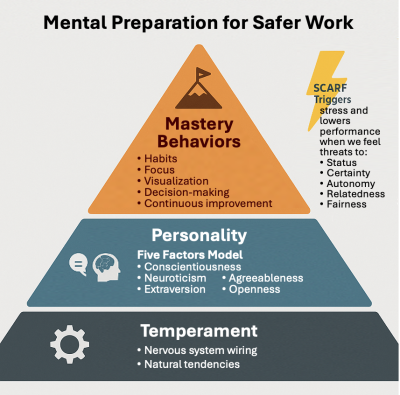

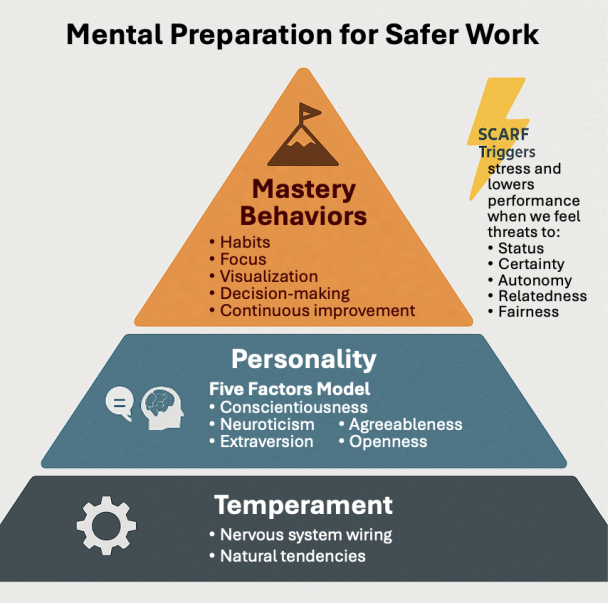

Frontline employees can develop the ‘right stuff’ through training, character development and good habit formation.

Mental Preparation for Safer Work

Used in combination, the Total Worker Health framework and motivational interviewing offer a proven way to foster lasting behavioral change.

When the System Isn’t Enough: How to Create Personal Motivation That Saves Lives

Author’s Note: In this article – the first in a five-part series – we explore the notion of accepting 100% accountability for our safety at work, just as we do at home. This is an act of self-preservation. The hope is that management’s safety focus will overlap with our own preparation. We want as much overlap as possible.

The next article will address mental preparation, which is different than…

Technology will become increasingly vital to industry safety and sustainability efforts over the next decade.

Forecasting the Future of Utility Safety: 10 Predictions for 2026 and Beyond

As we stand on the precipice of a new era in the utility sector, it is clear the future holds transformative potential driven by relentless technological progress.

We are already seeing not just small changes but a complete overhaul. The horizon is replete with innovations aimed at redefining safety protocols and operational efficiency. Predicted advancements – ranging from connected monitoring s…

‘Can I Be the Leader?’

Leadership continues to be a critical area of focus for utility safety and operations professionals. In my own career at Georgia Power, “Can I be the leader?” was a question I often asked myself and my employer. Now, in this installment of “Voice of Experience,” I am going to discuss the opportunit…

January-February 2026 Q&A

Q: We recently did some contract work in a manhole with live primary cables running through it. During an audit, the client’s safety team cited us for failure to have our manhole workers tied off to rescue lines. We had a tripod up and a winch ready for the three workers. What did we miss?

A: W…

Understanding how battery systems are governed under the OSHA standard is essential to ensuring employee safety.

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazard…

What’s Your Bucket IQ?

I know a lot about buckets, but it wasn’t until after I hung up my tools that I learned much of what I’m going to share with you in this article.

Background

I was lucky to work as a lineman when I did. The buckets we used at Florida Power & Light through the 1970s were unlined, simple fiber…

Understanding how battery systems are governed under the OSHA standard is essential to ensuring employee safety.

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazard…

Robust cable identification and remote cutting practices aid utility organizations in protecting workers, preserving system integrity and complying with regulatory standards.

Cable Identification and Cutting Safety for Medium-Voltage Splicers

A medium-voltage underground splicer’s ability to safely and correctly identify, test and cut cable is more than part of their job; it is a survival skill. These splicers must be trained to make their first cut remotely – every time – whether performing routine maintenance or responding to an emerg…

Strategically layering moisture-wicking, flame-resistant garments can enhance worker comfort without compromising safety.

Layer by Layer: Leveraging FR Clothing Systems for Hazard Protection and Comfort

Layering flame-resistant (FR) clothing has long been a best practice among industrial athletes. In addition to providing critical hazard protection, this tried-and-true strategy enhances user comfort by enabling industrial athletes to add or remove clothing layers as their activity level or the wea…

Social Networks

Recent Posts

Featured Products

Flight-Ready HEC Solutions

Buckingham offers flight-ready solutions for human external cargo (HEC) applications: the BuckFLIGHT HEC Harness (Non-Step In); Arc Tested Buck Access Tower Harness (Step In); and Arc Tested BuckTech Harness (Non-Step In).

Per FAA Policy Statement PS-AIR-27/29.865, ANSI Z359.11 full-body harness…

Safety Management

Layer by Layer: Leveraging FR Clothing Systems for Hazard Protection and Comfort

Layering flame-resistant (FR) clothing has long been a best practice among industrial athletes. In addition to providing critical hazard protection, this tried-and-true strategy enhances user comfort by enabling industrial athletes to add or remove clothing layers as their activity level or the wea…

Mental Preparation for Safer Work

Author’s Note: The first part of this five-part series (see https://incident-prevention.com/blog/when-the-system-isnt-enough-how-to-create-personal-motivation-that-saves-lives/) explored the notion of accepting 100% accountability for our safety at work. This article addresses mental preparation to…

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazard…

Inspecting the Fifth Wire: Winning the War on Lineworker Suicide

Lineworkers confront daily risks many can’t imagine – arc flashes, falls, electrocutions and more. Yet there’s a silent, insidious threat currently claiming more lives in the electric utility industry than any physical injury.

We’re talking about suicide.

Safety professionals dedicate their c…

Frontline employees can develop the ‘right stuff’ through training, character development and good habit formation.

Mental Preparation for Safer Work

Author’s Note: The first part of this five-part series (see https://incident-prevention.com/blog/when-the-system-isnt-enough-how-to-create-personal-motivation-that-saves-lives/) explored the notion of accepting 100% accountability for our safety at work. This article addresses mental preparation to…

Understanding how battery systems are governed under the OSHA standard is essential to ensuring employee safety.

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazard…

Utility organizations must recognize suicide as a grave personal injury, equipping the workforce with adequate mental health training and tools.

Inspecting the Fifth Wire: Winning the War on Lineworker Suicide

Lineworkers confront daily risks many can’t imagine – arc flashes, falls, electrocutions and more. Yet there’s a silent, insidious threat currently claiming more lives in the electric utility industry than any physical injury.

We’re talking about suicide.

Safety professionals dedicate their c…

To expand our collective intelligence and better protect the workforce, we must treat all employee concerns as predictions of unwanted outcomes.

Overcoming Safety’s Blind Spot

“If you’re not prepared to be wrong, you’ll never come up with anything original.” -Sir Ken Robinson

Innately curious and hardwired to seek order, humans often grasp onto the latest ideas and inventions that help us satisfy our need to understand the world around us. Don’t believe me? Consider g…

To expand our collective intelligence and better protect the workforce, we must treat all employee concerns as predictions of unwanted outcomes.

Overcoming Safety’s Blind Spot

“If you’re not prepared to be wrong, you’ll never come up with anything original.” -Sir Ken Robinson

Innately curious and hardwired to seek order, humans often grasp onto the latest ideas and inventions that help us satisfy our need to understand the world around us. Don’t believe me? Consider geocentricism, or…

Frontline employees can develop the ‘right stuff’ through training, character development and good habit formation.

Mental Preparation for Safer Work

Author’s Note: The first part of this five-part series (see https://incident-prevention.com/blog/when-the-system-isnt-enough-how-to-create-personal-motivation-that-saves-lives/) explored the notion of accepting 100% accountability for our safety at work. This article addresses mental preparation to…

Utility organizations must recognize suicide as a grave personal injury, equipping the workforce with adequate mental health training and tools.

Inspecting the Fifth Wire: Winning the War on Lineworker Suicide

Lineworkers confront daily risks many can’t imagine – arc flashes, falls, electrocutions and more. Yet there’s a silent, insidious threat currently claiming more lives in the electric utility industry than any physical injury.

We’re talking about suicide.

Safety professionals dedicate their c…

Used in combination, the Total Worker Health framework and motivational interviewing offer a proven way to foster lasting behavioral change.

When the System Isn’t Enough: How to Create Personal Motivation That Saves Lives

Author’s Note: In this article – the first in a five-part series – we explore the notion of accepting 100% accountability for our safety at work, just as we do at home. This is an act of self-preservation. The hope is that management’s safety focus will overlap with our own preparation. We want as…

Worksite Safety

Cable Identification and Cutting Safety for Medium-Voltage Splicers

A medium-voltage underground splicer’s ability to safely and correctly identify, test and cut cable is more than part of their job; it is a survival skill. These splicers must be trained to make their first cut remotely – every time – whether performing routine maintenance or responding to an emerg…

Forecasting the Future of Utility Safety: 10 Predictions for 2026 and Beyond

As we stand on the precipice of a new era in the utility sector, it is clear the future holds transformative potential driven by relentless technological progress.

We are already seeing not just small changes but a complete overhaul. The horizon is replete with innovations aimed at redefining sa…

The Evolution of Personal Protective Grounding: Part 2

Part 1 of this article began with discussion of the first American power systems, when lineworkers initially encountered the hazards of working on de-energized lines (see https://incident-prevention.com/blog/the-evolution-of-personal-protective-grounding-part-1/). This led to early personal protect…

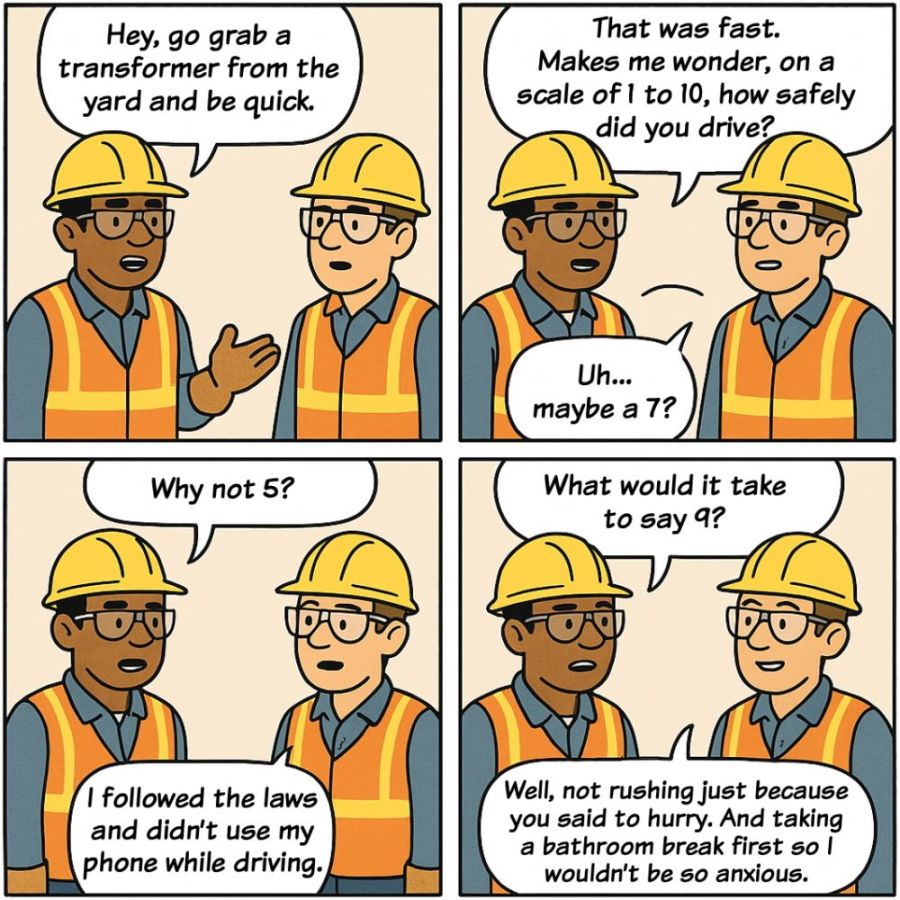

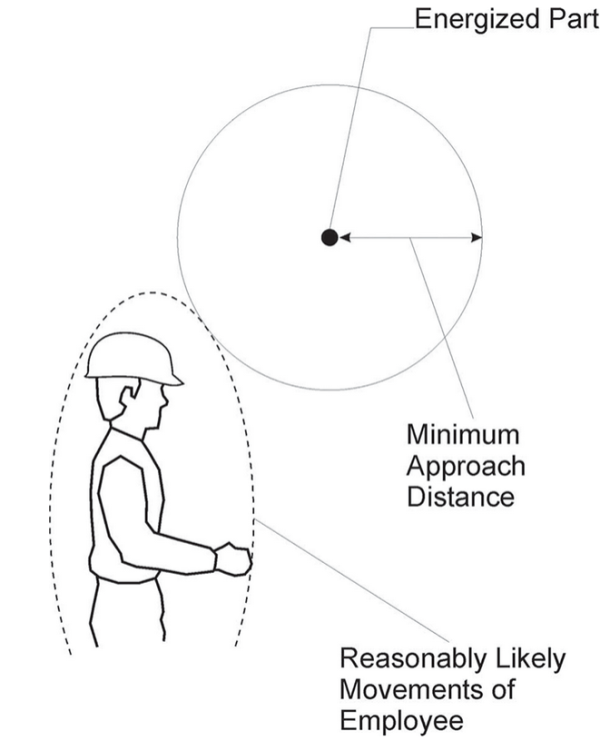

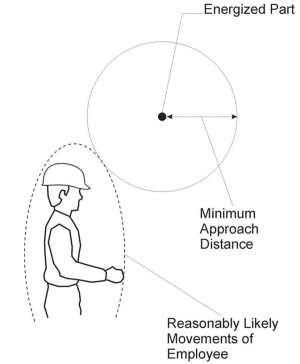

‘Avoid Contact’: Correctly Understanding the MAD Without a Distance

For decades, air has been used to effectively and inexpensively maintain phase-to-phase and phase-to-ground clearances of overhead distribution and transmission power lines and electrical equipment. Air’s extremely high resistance offers excellent protection against the passage of current. The grea…

Technology will become increasingly vital to industry safety and sustainability efforts over the next decade.

Forecasting the Future of Utility Safety: 10 Predictions for 2026 and Beyond

As we stand on the precipice of a new era in the utility sector, it is clear the future holds transformative potential driven by relentless technological progress.

We are already seeing not just small changes but a complete overhaul. The horizon is replete with innovations aimed at redefining sa…

PPG is equally as important today as it was a century ago, providing lineworkers with a critical safeguard against electrical hazards.

The Evolution of Personal Protective Grounding: Part 2

Part 1 of this article began with discussion of the first American power systems, when lineworkers initially encountered the hazards of working on de-energized lines (see https://incident-prevention.com/blog/the-evolution-of-personal-protective-grounding-part-1/). This led to early personal protect…

Electrical workers must recognize that ‘avoid contact’ requires them to rubber up or cover up – including when contact is possible with secondary voltages.

‘Avoid Contact’: Correctly Understanding the MAD Without a Distance

For decades, air has been used to effectively and inexpensively maintain phase-to-phase and phase-to-ground clearances of overhead distribution and transmission power lines and electrical equipment. Air’s extremely high resistance offers excellent protection against the passage of current. The grea…

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compliance systems and paperwork were in place. Yet we still failed our brothers and sisters.

That reality should eat at all of us because our industry could have done better then – and we should be doing better now. We must face the truth that not all safety methods work as intended. Without adjust…

Stephen Shutt, CUSP

Managing Overload: An Essential Safety Conversation

When I consider the advancements in the construction industry over the past 20 years, the emphasis on safety is one that immediately stands out. Today, we continue to strive to elevate our safety awareness, knowledge, training and program development – but that is only one side of the coin. On the…

Rob Duplain

6 Seasonal Strategies for Worker Well-Being

The holiday season is a time for family and celebration, but it is also one of the busiest times of year. Stress can easily creep in, creating safety hazards at work and at home. Staying mentally alert and focused during this period is key to preventing incidents.

Personal finances are among the…

Clint Lozar

Redefining Accountability in Utility Operations

Jamie Conn, CLCP

Peer Pressure, Trust and the Stewardship of Safety

Daniel Cooper, CSP, CUSP

Smart PPE: Enhancing Worker Safety and Operational Efficiency

Christian Connolly

Mistakes Are Inevitable: Choose to Invest in Recovery Capacity

Shawn M. Galloway

Disable Reclosing to Heighten Worker Protection

Ben Browne, CUSP

Use 2026 to focus on what you want, believe you can succeed, make plans to ensure you do and share your success stories.

‘I Am a Good Putter’: What Golf Teaches Us About Safety Success

During my trip to Glendale, Arizona, for the most recent iP Utility Safety Conference & Expo, I received the single greatest piece of golf instruction I have ever heard. Now I want to share it with you, particularly as it relates to safety.

But first, you may be wondering how I obtained such…

Here’s how you can become a brightly shining safety light in your organization.

Be the Light

“This little light of mine, I’m gonna let it shine, let it shine, let it shine, let it shine.”

Light. We literally cannot live without it.

In addition to sustaining life, light can be used in various other ways, including helping us to see clearly and sanitizing unsafe conditions. That sounds…

Verbal and Physical Triggers

Think before you act.

That may be the single best piece of timeless wisdom we ever receive, especially when it comes to safety. And while it’s a simple concept, it’s not always our natural response, potentially presenting difficulties during job execution and task performance.

Keeping in mind…

The E + R = O tool can help us optimize our response to any event, enhancing safety, relationships, decision-making and more.

Your Response Matters … A Lot

How you respond to other people and events matters. It matters a lot. Your responses – both as a leader and a member of the TEAM (Together Everyone Accomplishes More) – impact every part of your life, including culture, relationships and safety.

Let’s start with this: “Responding” is a task. To…

‘Can I Be the Leader?’

Leadership continues to be a critical area of focus for utility safety and operations professionals. In my own career at Georgia Power, “Can I be the leader?” was a question I often asked myself and my employer. Now, in this installment of “Voice of Experience,” I am going to discuss the opportunit…

Don’t Cross That Line

In this installment of “Voice of Experience,” I am going to share a safety perspective that struck a real chord with me when someone offered it during a recent meeting. My goal in passing it along during this season of reflection is to prompt readers to contemplate and continue refining their safe…

Accuracy Above All: Authoring Articles for iP Magazine

For over 17 years, I have had the distinct privilege of writing for Incident Prevention magazine. I am genuinely honored that iP continues to publish my articles. My first column was about the four principles of distribution cover-up. At last count, I had written and submitted more than 100 article…

Clearing Up Confusion About Host-Contractor Relationships

In my consulting work, I’ve found there is some industry confusion regarding the relationship between a host utility and an independent contractor company. To help provide clarity, I’m going to kick off this installment of “Voice of Experience” with an overview of each party’s obligations from an O…

January-February 2026 Q&A

Q: We recently did some contract work in a manhole with live primary cables running through it. During an audit, the client’s safety team cited us for failure to have our manhole workers tied off to rescue lines. We had a tripod up and a winch ready for the three workers. What did we miss?

A: We have received similar questions over the years, usually due to a misunderstanding of OSHA’s enclos…

December 2025 Q&A

Q: Can I ground through a wave trap?

A: General discussion about wave or line traps centers on their function. At operating frequency, they have extremely low impedance to any voltage at 60 Hz. Some would say that for the sake of convenience, it’s OK to ground at a switch even where there is a line trap on its load side. That is a bit too simplified. Historically, we isolated a transmission li…