Addressing Comfort and Contamination in Arc-Rated Clothing

With the revised OSHA 29 CFR 1910.269 standard slated to soon be released, the last utility companies holding out on moving to arc-rated clothing will soon be compelled to do so as a matter of law. The new standard is likely to have the same language as the National Electrical Safety Code (NESC) and will require arc flash calculations for both primary and secondary voltages. NESC 2007 excluded secondary voltages, but the 2012 edition includes a requirement to perform arc flash calculations and does not discriminate against primary or secondary voltages. To follow calculations per the updated 1910.269 standard, worker apparel will be required to have an arc rating equivalent to the hazard. Most of the PPE will be 4, 8, 12, 20, 40 and 60 cal/cm² as described in the NESC.

When an arc-rated PPE program is put into place, this type of change often raises complaints and questions that must be addressed. One of the most common complaints about arc-rated PPE is that it is hot, but this doesn’t have to be the case. However, if you compare moving from a cotton T-shirt to a long-sleeve shirt, this is certainly true. FR-treated, arc-rated cotton materials contain a polymer in the cotton fiber that makes them a little heavier, and some think it makes them feel hotter. Synthetic, nonmelting fibers are also often perceived as hotter, but all the materials have gotten better over the years due to the fibers being blended with hydrophobic and hydrophilic fibers to make them as comfortable as possible.

When considering worker comfort, take a close look at newer materials and employ wear trials during the summer to get the most realistic outcomes. Most people find khaki color cooler than postal blue or navy. By reviewing newer materials and comparing them to the old standbys, you might be surprised by what’s out there now. When we first started arc testing in 1994, there were just a few different fabrics available. Today, many new fabrics are tested each month. Things are changing.

Don’t Make the High Arc Rating Mistake

Most utilities make a common mistake – trying to make the base layer’s arc rating as high as possible – that they think will better protect workers. In reality, opting to do this makes the PPE hotter by putting workers in 8- to 12-cal/cm2 garments, which usually weigh 6 to 10 oz/yd2, when they have been used to wearing cotton that weighs 5 oz/yd2 or less. When you combine that with the probability that the workers are moving from wearing short-sleeve shirts to wearing long-sleeve shirts, you are asking for negative feedback.

For setup and travel, we recommend using a base layer that consists of a short-sleeve, arc-rated T-shirt. A long-sleeve, arc-rated shirt is recommended only when performing work that has the potential for arc flash exposure (i.e., voltage testing and live work). This makes the worker more comfortable and allows the company to ensure that no clothing ignitions will occur, while also offering another layer of protection when wearing the outer shirt.

Some of these T-shirt/outer shirt systems have arc ratings as high as 25 cal/cm², and many meet 20 cal/cm². Combined with a 15- to 20-cal/cm² pant, this gives most utility systems all the arc flash protection they need other than for the substation transformer secondary side or medium-voltage network systems with multiple feeds.

By finding the spots with higher arc flash incident energy and providing extra PPE – such as a coverall or flash suit – when performing tasks at these spots, you let the workers be more comfortable, more often. Long-sleeve shirts are more protective than short-sleeve shirts, but for lesser hazards that don’t necessitate long sleeves, workers will be more comfortable in short-sleeve shirts or T-shirts for most of the summer workday. In many cases it is more beneficial to wear an arc-rated T-shirt rather than a non-FR cotton T-shirt with an FR arc-rated outer shirt. With the arc-rated T-shirt/arc-rated shirt combination, there is more torso protection than needed and there is no risk of igniting a cotton T-shirt under or through the arc-rated outer shirt. Arc-rated welding sleeves can be used along with an arc-rated short-sleeve shirt or T-shirt to enhance arm protection while still allowing for a cooler option than wearing a long-sleeve shirt all day.

Answer the Contamination Question in Training

What about arc-rated PPE that is contaminated with sweat, dirt, transformer oil and grease, paint and other substances? This is a common question, and our IEEE Electrical Safety Workshop study goes a long way in answering it. For more information about the study, see Hoagland, H.; Smith, L.; Golovkov, M.; Burton, C.; Pailing, R.; Maurice, C., “Study of effects of mining industry contaminations on protective properties of arc rated clothing using ASTM F1959,” Electrical Safety Workshop (ESW), 2012 IEEE IAS, pp. 1-4, Jan. 31, 2012-Feb. 3, 2012.

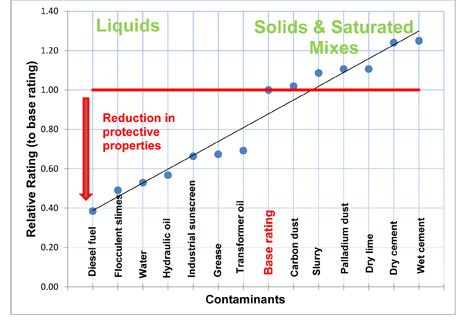

Figure 1: The relationship between arc thermal protection value (ATPV) and type of contaminant.

As shown in Figure 1, the bad news is that wet or liquid contaminants make a garment less protective by as much as 50 percent for sweat and much less protective for contaminants that ignite. In an arc exposure, the shell of the garment receives an intense heat. This heat conducts to the body better with a liquid present in the garment. The more liquid, the worse the arc rating becomes. The reduction in arc rating could be even greater for contaminants that ignite. Flammable contaminants ignite where the contaminant is on the garment. The good news is that FR garments are still better than ignitable garments.

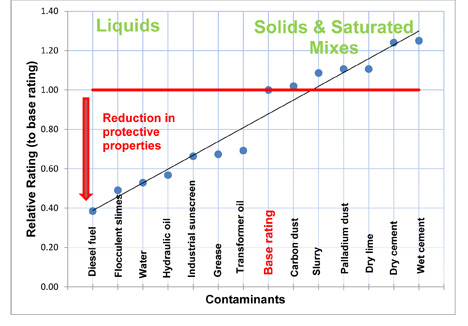

In the workshop study previously referenced, we found little change in protection for low levels of moisture – less than 5 percent weight moisture. The surprising finding was that the clothing looked better after the test flash exposure than the other contaminated samples. See Figure 2. It is assumed that intensive evaporation of the liquid contaminant during arc exposure provides enough cooling to keep the fabric’s surface temperature below the charring threshold. But at the same time, the temperature behind the wet fabric is rising high enough to cause second-degree skin burns while the fabric is not even scorched. This new understanding of how a garment looks when wet has helped in several accident investigations in the past five years when clothing looked better than the burns received would have suggested.

Figure 2: Effect of liquid contaminants on the degree of fabric charring in an arc flash exposure. Water makes the cloth look better, but the burns occurred at about half the incident energy of a relatively dry fabric.

When training workers, be upfront. They could receive more second-degree burns from a wet shirt, but it will not ignite and continue to burn if it is arc-rated. Only the area of the body closest to an arc exposure will have a chance of skin burns if a garment is not ignited. This is why lighter, quickly drying layers work better than a heavier 8- to 12-cal/cm² shirt.

As more workers have moved into arc-rated garments, fatalities have continued to decrease, but arc-rated clothing doesn’t prevent contact with live conductors and doesn’t mean you will never experience skin burn. The percentage of burn area is likely to be much lower with arc-rated garments because no part of the garment will ignite, so burns are usually limited to the side and quadrant of the body exposed to the arc. Most arc flash incidents are less than 25 percent body burn when arc-rated clothing is worn (see Doan, D.R.; Hoagland, E.; Neal, T., “Update of field analysis of arc flash incidents, PPE protective performance and related worker injuries,” Electrical Safety Workshop (ESW), 2010 IEEE IAS, pp. 80-87, Feb. 1-5, 2010).

Clean Clothing Regularly and Properly

To keep any fear in check, a small amount of any of these contaminants is not likely to be life threatening, but large amounts or a buildup of hydrocarbons – called hydrocarbon loading – can be dangerous. We recommend cleaning garments regularly and properly. Industrial laundries do an excellent job of removing hydrocarbons. A home laundry was shown in our testing to remove the flammability of the hydrocarbon, but home laundering does not do as good of a job on stain removal as industrial laundering does. If home laundering leaves a smell of the hydrocarbon, wash the garment again. It is rare that there is enough of the soil left to ignite, but safety is the key. This is especially true of creosote, which we detect with our noses in very low concentrations.

Some companies pay for dry-cleaning after a garment is exposed to hydrocarbons, as this is quite effective in removing them. However, first you need to be sure that the material can be dry-cleaned. We have tested creosote and even stained garments that still smelled of creosote, but they have not been flammable in our testing. After washing them and even hugging a pole, they did not transfer enough creosote to cause ignition.

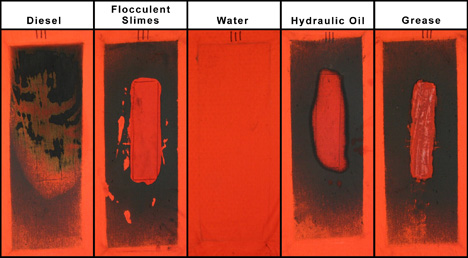

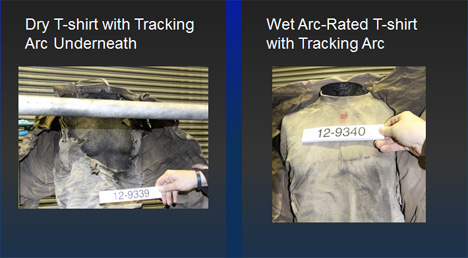

Figure 3: The difference in damage between dry and wet T-shirts exposed to a tracking arc.

While the ATPV does drop for a wet or sweaty garment, we have seen some protective effect of moisture in arc-rated garments in the case of body contact with medium-voltage live parts. An area of the wet shirt may have a waveguide effect and conduct the current around the worker, but not through the worker’s body. This effect is explained by the fact that the wet garment’s impedance is lower than the human body’s impedance. Fault current diversion may cause less internal injury and less risk of heart fibrillation, but it may still allow some skin burns under the arc-rated garments. This theory is being investigated; however, several anecdotal incidents seem to lead to this conclusion.

In Figure 3, you can see the effect of an 8-kV arc exposure on a wet shirt versus a dry shirt. A combination of an arc-rated T-shirt and overshirt was used for the testing. In one arc exposure, the T-shirt was dry, and it was wet in the second exposure. The mannequin used in the test was nonconductive, but a tracking arc under the overshirt took place in both cases. The dry T-shirt received more arc char damage than the wet shirt. Even though the wet T-shirt looked better, it may not correlate with the skin burn. Our research indicates that might not be the case. Wet, good-looking T-shirts might allow more burns. This makes the process of accident investigation trickier, but explains some unexpected burns in investigations from the past.

To summarize, workers walk away from arc events with no or very few burns when they:

• Wear the right garment for the exposure.

• Don’t wear too much PPE, thinking that more is always better. Sweating is not your friend in an arc flash.

• Make sure that all outermost layers are arc-rated and reasonably clean.

• Don’t wear melting materials next to the skin.

About the Authors: Hugh Hoagland and Mikhail Golovkov are ArcWear.com arc flash testing consultants. They are also training and accident investigation consultants for e-Hazard.com.