Tag: Worksite Safety

Eyes on the Wire: The Year of Actively Caring

Written by Addy Apesos on . Posted in Safety Management, Worksite Safety.

Using Power Tools in the Bucket

Written by Ryan Berg and Jim Olson on . Posted in Worksite Safety.

Matted Surfaces: Safety Considerations and Controls

Written by Nathan Boutwell, M.Eng., CSP, SMS, CIT, CUSP; Nick Powers; and Bill Hinrichs, CUSP on . Posted in Worksite Safety.

3 Sustainability Considerations When Evaluating FR/AR Apparel

Written by Josh Moody on . Posted in Worksite Safety.

Advancing Workforce Skills Using Simulation-Based Training

Written by Christa Fairchild on . Posted in Worksite Safety, Equipment Operations.

Understanding Wind Speed Limitations on Utility Equipment

Written by Jim Olson on . Posted in Worksite Safety, Equipment Operations.

The Case for Enhanced First-Aid Training for Lineworkers

Written by Bill Martin, CUSP, NRP, RN, DIMM on . Posted in Worksite Safety.

June – July 2022 Q&A

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety, Q & A.

Best Practices for Bucket Truck Rescue

Written by Ty Fenton on . Posted in Worksite Safety.

Heat Injury and Illness Prevention: Past, Present and Future

Written by Mike Starner, CUSP, CHST on . Posted in Worksite Safety.

Grounding Conductor Confusion: What’s the Best One to Use?

Written by Stephen Oaks on . Posted in Worksite Safety, Grounding.

Lineworkers and Line-Clearance Workers: Understanding Their Similarities and Differences

Written by Philip Moran, CTSP, CUSP on . Posted in Worksite Safety.

Actionable Safety: Modeling Change for Line Crews

Written by Bill Martin, CUSP, NRP, RN, DIMM on . Posted in Worksite Safety.

A Historical Review of Workplace Safety in the U.S.

Written by Rayford “RL” Grubbs, CUSP on . Posted in Worksite Safety.

Establishing a Comprehensive Ergonomics Program During a Pandemic

Written by Lisa Harris on . Posted in Worksite Safety.

Building an ATV/UTV Training Program for Utilities and Contractors

Written by Ty Fenton and Chuck Kevwitch on . Posted in Worksite Safety, Equipment Operations.

FR/AR Clothing Considerations During the COVID-19 Pandemic

Written by Derek Sang and Scott Margolin on . Posted in Worksite Safety.

Drive Safe. Work Safe. Save Lives.

Written by Marilyn M. Velez, MPH on . Posted in Worksite Safety, Tailgate Topics.

Minimum Approach Distances: What’s Required?

Written by Matt Edmonds, CUSP, CIT, CHST, and Pam Tompkins, CSP, CUSP on . Posted in Worksite Safety, OSHA Articles.

Fire Extinguisher Use and Safety for Utility Workers

Written by Steve Nash on . Posted in Worksite Safety.

Arc Rating Standards for Personal Protective Equipment

Written by Zarheer Jooma, P.E., and Hugh Hoagland on . Posted in Worksite Safety.

Why are Job Briefings and Risk Assessments Important?

Written by Matt Edmonds, CUSP, CIT, CHST, and Pam Tompkins, CSP, CUSP on . Posted in Worksite Safety, OSHA Articles.

What are OSHA’s Training Requirements?

Written by Matt Edmonds, CUSP, CIT, CHST, and Pam Tompkins, CSP, CUSP on . Posted in Worksite Safety, OSHA Articles.

Are You Using Your Five Senses to Stay Safe?

Written by Michael Stremel, CUSP on . Posted in Worksite Safety.

I’ve Got Your Back: Lessons in Socio-Biomimicry

Written by Alden B. Davis on . Posted in Worksite Safety.

Safety Success During an Insulating Boom Flashover

Written by Jace Kerby on . Posted in Worksite Safety.

Best Practices for Using Your Aerial Device Jib to Handle Transformers

Written by Roger Crom and Jim Olson, P.E. on . Posted in Worksite Safety, Equipment Operations.

Mother Nature vs. FR/AR Clothing

Written by Derek Sang, CSHEP, QSSP on . Posted in Worksite Safety.

Working in Switchgear Cubicles Just Got Safer

Written by Eric M. Fell on . Posted in Worksite Safety.

Take Your Time and Follow the Rules – Or Pay the Price

Written by Luis Ortega, CUSP Emeritus on . Posted in Worksite Safety.

Are You Taxing the Variables?

Written by Bill Martin, CUSP, NRP, RN, DIMM on . Posted in Worksite Safety.

When OSHA Knocks

Written by Dennis Childress on . Posted in Worksite Safety.

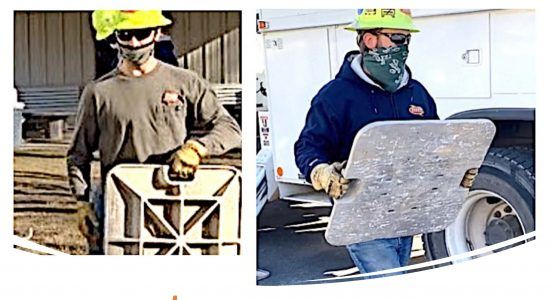

Using Situational Awareness to Enhance Field Security

Written by Jim Willis, CMAS, CHS-V on . Posted in Worksite Safety.

The Safe Use of Outrigger Pads for Equipment Stability

Written by Jeff Steiner on . Posted in Worksite Safety.

Emergency Response Training for Electric Utility Workers

Written by Mark Werndorf, CUSP on . Posted in Worksite Safety.

Investigating and Documenting Slips, Trips and Falls

Written by Chip Darius, CUSP, OHST, CET, CSHO on . Posted in Worksite Safety.

Strength and Conditioning Strategies to Prepare the Next-Generation Utility Worker

Written by Jeremy Verrillo, ATC, CEAS III, CWcHP, CMMSS on . Posted in Worksite Safety.

Overcoming Conflict on the Right-of-Way

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Worksite Safety.

The Hard Hat Celebrates 100 Years

Written by Stacey Simmons on . Posted in Worksite Safety.

How Hawaii Electric Light Co. Protected Employees During a Lava Flow

Written by David Spooner on . Posted in Worksite Safety.

Using Task-Based Work Assignments to Create Proficient Crews

Written by Debbie Dickinson on . Posted in Worksite Safety.

Enhancing Safety for Line Patrol Technicians

Written by Rob D. Adams, CLCP, CUSP, and Pete Prast, P.E. on . Posted in Worksite Safety, Equipment Operations.

Train the Trainer 101: The Value of a Site-Specific Health and Safety Plan

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety, Train the Trainer 101.

Innovative Fire Suppression Solutions for System and Worker Safety

Written by Edward Morson and Mark Green on . Posted in Worksite Safety.

Key Concepts of an Insulate and Isolate Program

Written by Danny Bost, CUSP on . Posted in Worksite Safety.

Using Technology to Eliminate Aerial Device Overloads

Written by Dan Brenden on . Posted in Worksite Safety, Equipment Operations.

Safety Concerns When Setting Wooden Utility Poles

Written by Luis Ortega, CUSP Emeritus on . Posted in Worksite Safety.

Understanding Hypothermia in the Outdoor Work Environment

Written by Arthur Seely and Steve Andreas on . Posted in Worksite Safety.

Overcoming Barriers to Crane and Rigging Skills Development

Written by Debbie Dickinson on . Posted in Worksite Safety, Equipment Operations.

October 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety, Q & A.

7 Electrical Theory and Circuitry Myths – Busted

Written by Dave Johnson, CUSP, and Mack Turner, CUSP on . Posted in Worksite Safety.

The Science of Keeping Workers Safe

Written by Raffi Elchemmas, MBA, AEP, and Sarah Hall on . Posted in Worksite Safety.

Voice of Experience: De-Energizing Lines and Equipment for Employee Protection

Written by Danny Raines, CUSP on . Posted in Worksite Safety, Voice of Experience.

August 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Grounding.

Making Sense of Protection Requirements for Open-Air Arc Flash Hazards

Written by Lee Marchessault, CUSP on . Posted in Safety Management, Worksite Safety.

Injury Risks Associated with Climbing in the Wind Energy Generation Industry

Written by Naira Campbell-Kyureghyan, Ph.D. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Training and Verification Requirements for the Safety of Electric Utility Workers

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Qualified and Task-Specific Electrical Worker Training

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety.

June 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

Confined Space Training: It Has to Be Done Right the First Time

Written by Tony Barton on . Posted in Safety Management, Worksite Safety.

Shining a Light on Ventilation Systems and Surveys in the Electric Power Industry

Written by Connie L. Muncy, CIH, CUSP, MS, REM on . Posted in Safety Management, Worksite Safety.

Marking a Safety Milestone at Silicon Valley Power

Written by Damon Beck on . Posted in Safety Management, Worksite Safety.

Using Thermography for Underground Worker Safety

Written by Peter Tyschenko and Michael Meathe on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Addressing Common Fall Protection Questions and Concerns

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

April 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A.

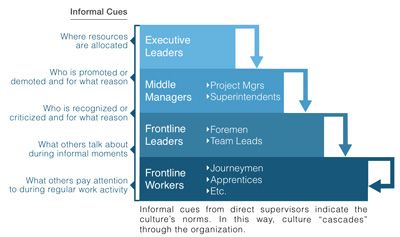

Frontline Fundamentals: Risk Tolerance

Written by David McPeak, CUSP, CIT, CHST, CSP, CSSM on . Posted in Safety Management, Leadership Development, Worksite Safety, Frontline Fundamentals.

Equipotential Grounding: Lessons Learned in the Field

Written by Dwight Miller, CLCP, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Understanding and Preventing Lower Back Pain in the Electric Utility Industry

Written by Dr. Andrew Murro, DC, DABCO on . Posted in Safety Management, Worksite Safety.

Maximizing Your Arc-Rated Gear

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: The New Walking-Working Surfaces Final Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Inspection, Maintenance and Fall Protection Guidance for Bucket Truck Use

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience, Equipment Operations.

February 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety, Q & A, Equipment Operations.

New Updates to the National Electrical Safety Code

Written by Sam Stonerock on . Posted in Safety Management, Worksite Safety.

Emergency Preparedness for Remote Winter Work Locations

Written by Todd Horning on . Posted in Safety Management, Worksite Safety.

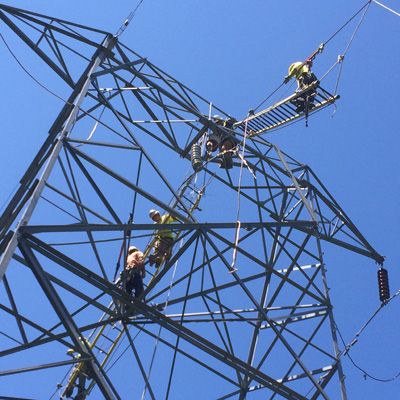

Rope Access for Live-Line Work

Written by Thomas Penner on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Train the Trainer 101: Understanding Canine Behavior for the Protection of Utility Workers: Part Two

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Switching and Working on UD Systems

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience, Equipment Operations.

December 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

Safety Best Practices for Outage Season

Written by Jordan Hollingsworth, CHST, CSP, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Assimilating Short-Service Employees Into Your Safety Culture

Written by Phillip Ragain on . Posted in Safety Management, Leadership Development, Worksite Safety.

Underground Electrical Vaults: Safety Concerns and Controls

Written by Chris Grajek, CRSP, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Understanding Canine Behavior for the Protection of Utility Workers

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: OSHA’s MAD Changes and a Missed Opportunity

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

October 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations.

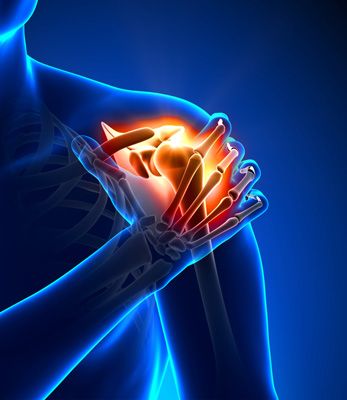

The Causes and Prevention of Shoulder Injuries in the Electric Distribution Field

Written by Dr. Andrew Murro, DC, DABCO on . Posted in Safety Management, Worksite Safety.

The Road to an Innovative, Award-Winning Safety Program

Written by Brad Stout and Jesse Gibbon on . Posted in Safety Management, Leadership Development, Worksite Safety.

Tricks of the Trade to Improve the Trenching Environment

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Practical Personal Grounding in Underground Work

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: OSHA Requirements for Step Potential Protection

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

August 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations.

10 Tips for Better Incident Investigations

Written by Thomas Ray, CSP, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety, Tailgate Topics.

Protective Systems for Trenching and Excavations

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

The Job Brief’s Hidden Influence on Utility Safety

Written by Michael Burnham, CSP, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety.

Fire Restoration Best Practices for Utilities

Written by Chris Grajek, CRSP, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Practical Recommendations for Wire Stringing

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101, Equipment Operations.

Confined Spaces in Construction

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety.

June 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

Don’t Leave Employees to Fill in the Blanks

Written by Dave Sowers on . Posted in Safety Management, Leadership Development, Worksite Safety.

Soil Mechanics in the Excavation Environment

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety.