Tag: Worksite Safety

The Future of Ergonomics

Written by Raffi Elchemmas, AEP, MBA on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Grounding for Stringing in Energized Environments

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101, Equipment Operations, Grounding.

Voice of Experience: OSHA Citations and Informal Conferences

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

April 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A.

Trenching by the Numbers

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Understanding Your Safety DNA

Written by Neil Dempster, CSP, MBA, Ph.D. on . Posted in Safety Management, Leadership Development, Worksite Safety.

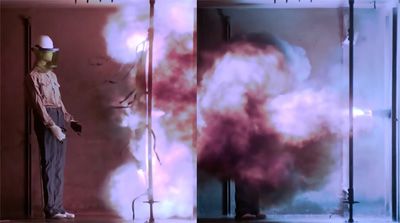

Best Practices for Arc-Rated Clothing Programs

Written by Hugh Hoagland on . Posted in Safety Management, Worksite Safety.

Auditing for Safety Improvement

Written by Kathy Ellsworth, CUSP, and Pam Tompkins, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Safety Cops and the Continuum of Safety

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety, Tailgate Topics.

Voice of Experience: Hand and Skin Protection for Electric Utility Workers

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

February 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Grounding.

Stringing Best Practices: Mesh Grips vs. Preforms

Written by Chris Grajek, CRSP, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

RF Safety for Utility Workers

Written by Miranda Allen on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Practical Underground Safety: Handling Neutrals and Rescue

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: PPE Regulatory and Consensus Standard Requirements

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

December 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

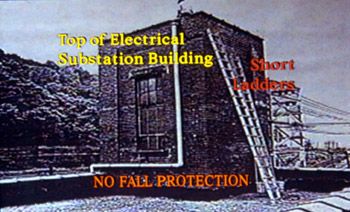

Fundamentals of Substation Rescue Plans

Written by R. Scott Young, CUSP on . Posted in Safety Management, Worksite Safety.

Investigating Industrial Hygiene at Salt River Project

Written by Randi Korte, CUSP on . Posted in Safety Management, Worksite Safety.

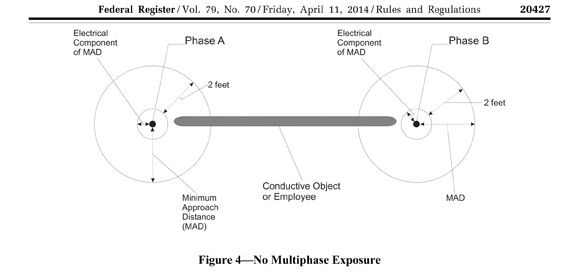

Train the Trainer 101: Practical MAD and Arc Flash Protection

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: Clearing Up Confusion About 1910.269

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

October 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

N95 Filtering Face Pieces: Where Does Your Organization Stand?

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Stepping Up Steel Safety Education

Written by Keith Lindemulder on . Posted in Safety Management, Leadership Development, Worksite Safety.

Rigging Fundamentals for Utilities

Written by Brian S. Hope, ASP, CSP, CUSA on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Arc Flash Mitigating Technologies and the OSHA Final Rule

Written by Samy Faried on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Practical Personal Protective Grounding

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Voice of Experience: Power Generation Safety and the OSHA Update

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

August 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Making the Switch

Written by Raffi Elchemmas, AEP, MBA on . Posted in Safety Management, Worksite Safety, Equipment Operations.

How to Navigate the FR Clothing Marketplace

Written by Derek Sang, CSHEP, QSSP on . Posted in Safety Management, Worksite Safety.

Arrive Alive

Written by Laura McMillan on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Train the Trainer 101: Back to Basics: ‘Gentlemen, This is a Football’

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

June 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

OSHA and the Host-Contractor Relationship

Written by Ted Granger, CSSBB, CUSP on . Posted in Safety Management, Worksite Safety.

The Roller-Coaster Life Cycle of IEEE 1307

Written by Ed Hunt, CUSP on . Posted in Safety Management, Worksite Safety.

Facing Unique Challenges

Written by Kekai Batungbacal, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety.

Train the Trainer 101: The OSHA-EEI Subpart V Settlement

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Voice of Experience: OSHA Updates to Arc-Rated FR Clothing Requirements

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

April 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

The Importance of Matching Evidence Marks in Accident Investigations

Written by Allen L. Clapp, P.E. on . Posted in Safety Management, Worksite Safety.

Measuring, Planning and Cutting Methods for Chainsaw Operators

Written by Ken Palmer on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Recent PPE Changes and 2015 Trends

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Addressing Anchorages

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: The Importance of Job Briefings

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

February 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Arc Flash and the Benefits of Wearing PPE

Written by Michael J. Getman, CUSP, MBA on . Posted in Safety Management, Worksite Safety.

Closing the Safety Gap

Written by Thomas Arnold, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Chainsaw Safety, Planning and Precision Felling Techniques

Written by Ken Palmer on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Train the Trainer 101: Substation Entry Policies

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

December 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Photovoltaic Solar Safety Management for Utilities

Written by Jeff Court, CUSP on . Posted in Safety Management, Worksite Safety.

The Risks and Rules of Chainsaw Operation

Written by Ken Palmer on . Posted in Safety Management, Worksite Safety, Equipment Operations.

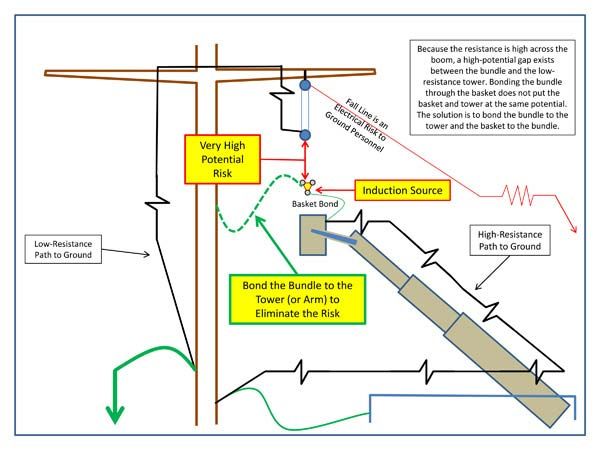

Train the Trainer 101: Stringing in Energized Environments

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Voice of Experience: Flame-Resistant Apparel is Now PPE

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

October 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

SRP Rope Access Program Addresses Towers of Power

Written by Randi Korte, CUSP on . Posted in Safety Management, Worksite Safety.

Responding to Pole Fires

Written by Jim Boyd, CUSP, and Craig Lohrey on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Fall Protection and the New Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: OSHA Eye and Face Protection Standards

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

August 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

The Final Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

NFPA 70E Arc Flash Protection for Nonexempt Industry Workers

Written by Jim Phillips, P.E. on . Posted in Safety Management, Worksite Safety.

June 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

Voice of Experience: Understanding Enclosed and Confined Spaces

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

Accident Analysis Using the Multi-Employer Citation Policy

Written by Allen L. Clapp, P.E. on . Posted in Safety Management, Worksite Safety, Tailgate Topics.

Understanding and Influencing the ‘Bulletproof’ Employee

Written by Phillip Ragain on . Posted in Safety Management, Leadership Development, Worksite Safety.

Electrical Safety for Utility Generation Operations Personnel: A Practical Approach

Written by Randy Fabry and Pam Tompkins, CSP, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Fact-Finding Techniques for Incident Investigations

Written by Ron Joseph, CUSP on . Posted in Safety Management, Worksite Safety.

What OSHA’s Proposed Silica Rule Means to You

Written by Matt Edmonds, CUSP, CHST, CET on . Posted in Safety Management, Worksite Safety.

The Singing Lineman

Written by Loralee Pearson on . Posted in Worksite Safety.

Voice of Experience: Working On or Near Exposed Energized Parts

Written by Danny Raines, CUSP on . Posted in Worksite Safety, Voice of Experience.

Are Your Temporary Protective Grounds Really Protecting You?

Written by Marcia L. Eblen and Rick Kennerly on . Posted in Worksite Safety, Grounding.

Ergonomics for Lineworkers

Written by Steve Hedden, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: Incidents and the Failure to Control Work

Written by Danny Raines, CUSP on . Posted in Worksite Safety, Voice of Experience.

Starting From the Ground Up

Written by John Morton, CUSP on . Posted in Worksite Safety.

Safety Awareness for Substations

Written by R. Scott Young, CUSP on . Posted in Worksite Safety.

Occupational Dog Bite Prevention & Safety

Written by Ron Joseph, CUSP on . Posted in Worksite Safety.

NESC and ANSI Z535 Safety Sign Standards for Electric Utility Power Plants and Substations

Written by Allen L. Clapp, P.E. on . Posted in Worksite Safety.

Public Safety and Our First Responders

Written by George R. Popovici, CUSA, CUSP on . Posted in Worksite Safety.

Implementing a Zero Injury Program

Written by Joseph Saccaro, CSP, CUSA, CUSP, OHST on . Posted in Worksite Safety.

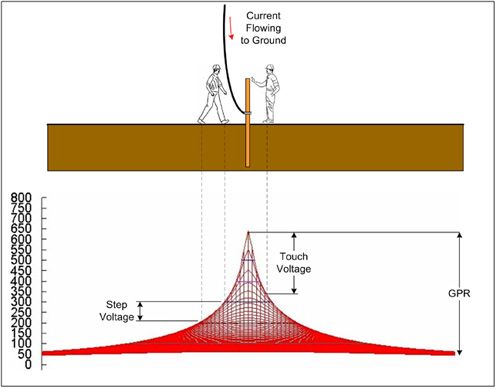

Detecting Shock Hazards at Transmission Line Work Sites

Written by Gary Zevenbergen on . Posted in Worksite Safety, Tailgate Topics.

Train the Trainer 101: Enclosed Space Rescue

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

Train the Trainer 101: Ferroresonance Explained

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

Keys to Effective Fall Protection

Written by Mike Woods, CUSP on . Posted in Worksite Safety.

Safety Rules and Work Practices: Why Don’t They Match Up?

Written by Jeremy Adcock and Pam Tompkins, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Working in Winter

Written by Amber Reed on . Posted in Worksite Safety.

100 Percent Fall Protection: A Joint Union-Management Effort

Written by Kevin J. Severson, CUSA on . Posted in Worksite Safety.

ATV Safety Begins with Proper Training

Written by Todd Horning on . Posted in Worksite Safety.

Arc Suppression Blanket Installation

Written by Victor L. Petrovic, Ph.D. on . Posted in Worksite Safety.

What Do We Do About Arc Hazard?

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

What You Need to Know About Substations

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

Tower Rescue Pre-planning Pays Off

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

4 Rules to Live By

Written by Danny Raines, CUSP on . Posted in Worksite Safety, Grounding.

Notes From the Underground

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

Why Single-Point Grounding Works

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety, Grounding.