Tag: Safety Management

7 Secrets of Root Cause Analysis

Written by Mark Paradies and Alex Paradies on . Posted in Safety Management.

Gauges: How Do You Measure Safety?

Written by Dwight Miller, CLCP, CUSP on . Posted in Safety Management, Leadership Development.

Industry Trends and Solutions to Improve Worker Readiness

Written by Kyle Schmoyer and Kris Corbett on . Posted in Safety Management.

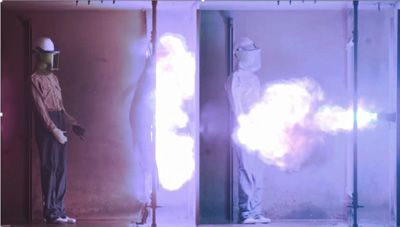

Thermal Protection for Electrical Work

Written by Zarheer Jooma, P.E., Brian Shiels and Stacy Klausing, M.S. on . Posted in Safety Management.

The 8 Habits of a Highly Effective Safety Culture

Written by Rod Courtney, CUSP on . Posted in Safety Management.

Closing the Cracks with the FMCSA’s Drug and Alcohol Clearinghouse

Written by Joshua Reilly, SMS, CIT, CUSP on . Posted in Safety Management.

Beyond Behavior-Based Safety: Why Traditional Safety Practices are No Longer Enough

Written by Joseph White on . Posted in Safety Management, Leadership Development.

Mitigating Heat and Cold Stress with FR/AR Clothing

Written by Derek Sang, CSHEP, QSSP on . Posted in Safety Management.

Designing a Safe and Reliable Electrical Maintenance Program

Written by Martin Robinson, IEng., CMRP, CRL on . Posted in Safety Management.

Increasing Worker Confidence and Competence

Written by William N. Martin, CUSP, NRP, RN, DIMM on . Posted in Safety Management.

Using PPE to Bolster Safety Resilience

Written by Scott Francis on . Posted in Safety Management.

Safety Advancements in the Line-Clearance Industry

Written by John Sullivan , CUSP on . Posted in Safety Management.

ANSI A92.2: 2022 Changes and Training Requirements

Written by Phil Doud on . Posted in Safety Management, Equipment Operations.

Security in the Field: A Largely Unnoticed Need

Written by Jim Willis, CMAS, CHS-V on . Posted in Safety Management.

Electrical Arc Flash and Shock Hazards for Fall Protection Using ASTM F887

Written by Hugh Hoagland and Stacy Klausing, M.S. and Zarheer Jooma on . Posted in Safety Management.

Managing Risk Through Cognitive Impairment Testing

Written by Lee Marchessault and Peri Eryigit on . Posted in Safety Management.

Are Your Lessons Learned Making Your Workers Safer?

Written by William N. Martin, CUSP, NRP, RN, DIMM on . Posted in Safety Management.

Lagging Indicators, Leading Indicators … Let’s Start Over

Written by Pam Walaski, CSP on . Posted in Safety Management.

Overcome ‘Burnt Toast Syndrome’ to Improve Safety and Training Results

Written by Mack Turner, CUSP on . Posted in Safety Management.

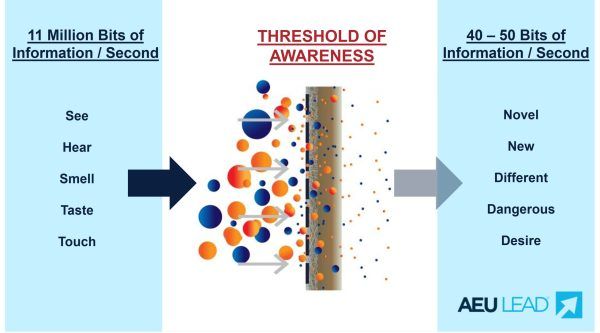

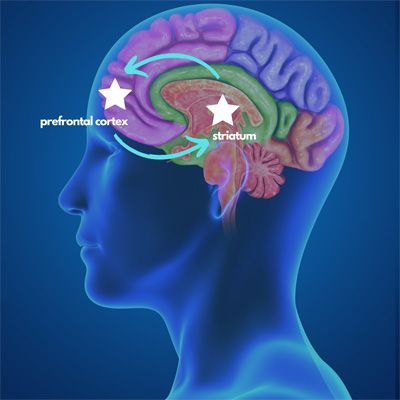

The Biological Basis of Complacency

Written by Sharon Lipinski on . Posted in Safety Management.

My Shocking Awakening: Lessons Learned From a High-Voltage Contact

Written by Lito Wilkins, CUSP on . Posted in Safety Management.

Leading Change Through Faith, Hope and Tough Love: Part II

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Safety Management.

Leading Change Through Faith, Hope and Tough Love: Part I

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Safety Management.

Line and Substation Insulator Refresher

Written by R. Scott Young, CUSP on . Posted in Safety Management.

Safe Transportation of Leaking Transformers

Written by Patrick F. McAtarian on . Posted in Safety Management.

The Hierarchy of Incidents and Learning: Part II

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Safety Management.

The Hierarchy of Incidents and Learning: Part I

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Safety Management.

Arc Flash Considerations for Utility and Construction Activities: Part II

Written by Zarheer Jooma, P.E., and Hugh Hoagland on . Posted in Safety Management.

The Field Observation: A Proactive Safety Methodology

Written by Lee Marchessault, CUSP on . Posted in Safety Management.

Arc Flash Considerations for Utility and Construction Activities

Written by Zarheer Jooma, P.E., and Hugh Hoagland on . Posted in Safety Management.

Breaking Down Barriers: Using Data as a Tool in the Driver Safety Communication Process

Written by Art Liggio on . Posted in Safety Management.

Establishing and Evaluating a Value-Driven Safety Culture

Written by Matt Edmonds, CUSP, CHST, CET on . Posted in Safety Management.

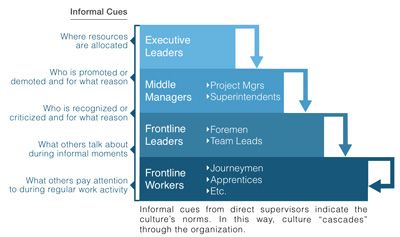

Organizational Safety Roles and Responsibilities

Written by Michael Kleinpeter, M.Eng., CUSP, CHST on . Posted in Safety Management.

Understanding, Selecting and Caring for FR/AR Clothing

Written by Derek Sang, CSHEP, QSSP on . Posted in Safety Management.

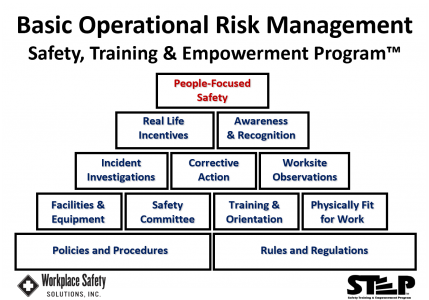

Five Essentials of Successful Safety Programs

Written by Thomas Arnold, CSP, CUSP on . Posted in Safety Management.

Are Compliance Grungs Taking Over Your Organization?

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

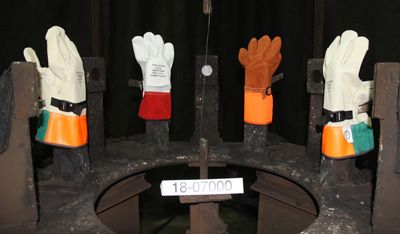

Specifying Arc-Rated and Flame-Resistant Gloves

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management.

Recognizing Our Human Risk Factors

Written by William N. Martin, CUSP, NRP, RN, DIMM on . Posted in Safety Management.

Controlling Struck-By Hazards in Utility Work Zones

Written by Chip Darius, CUSP, OHST, CET, CSHO on . Posted in Safety Management.

Are Your Substations Safe?

Written by Lee Marchessault, CUSP on . Posted in Safety Management.

Why Employees are Silent When Near Misses Occur

Written by Chris Court, CSP on . Posted in Safety Management.

Rubber Insulating Sleeves and Arc Flash Protection

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management.

Live Safely: The OG&E Way

Written by Trisha Bilyeu on . Posted in Safety Management.

Voice of Experience: The Value of Worker Training

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

When Utilities Leave the Pavement: Off-Road Driving Safety Challenges

Written by Steve Andreas on . Posted in Safety Management, Equipment Operations.

Empowering Employees to Take Care of Themselves

Written by Peter P. Greaney, M.D. on . Posted in Safety Management.

Voice of Experience: Understanding Induced Voltage

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

June-July 2018 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Grounding.

Rethinking Utility Security

Written by Jim Willis, CMAS, CHS-V on . Posted in Safety Management.

Scenario-Based Fall Protection Solutions

Written by Rob D. Adams, CLCP, CUSP on . Posted in Safety Management.

Three Overlooked Processes for Increasing Safe Work Practice

Written by Bart Castle on . Posted in Safety Management.

How to Develop a Contractor Safety Management Standard

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

Using Arc Protective Blankets as an Engineering Control Method

Written by Hugh Hoagland and Zarheer Jooma, BSEE, M.S. on . Posted in Safety Management.

Chris Grajek Honored at 2017 USOLN Safety Award Ceremony

Written by Kate Wade on . Posted in Safety Management.

What Changes When You Put a Face on Safety?

Written by Molly Hall on . Posted in Safety Management.

Secondary FR Garments: Practical Solutions for Protection

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management.

Safety Concerns When Working In and Around Manholes and Vaults

Written by Michael Stremel, CUSP on . Posted in Safety Management, Tailgate Topics.

Train the Trainer 101: Practical Aviation for Power-Line Applications

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Distribution Cover-Up: Why Wouldn’t You Use It?

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Rope Access Work in Today’s Line Trade

Written by Brian Bourquin on . Posted in Safety Management, Equipment Operations.

August 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Grounding.

Making Sense of Protection Requirements for Open-Air Arc Flash Hazards

Written by Lee Marchessault, CUSP on . Posted in Safety Management, Worksite Safety.

Injury Risks Associated with Climbing in the Wind Energy Generation Industry

Written by Naira Campbell-Kyureghyan, Ph.D. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Training and Verification Requirements for the Safety of Electric Utility Workers

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Qualified and Task-Specific Electrical Worker Training

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety.

June 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

Confined Space Training: It Has to Be Done Right the First Time

Written by Tony Barton on . Posted in Safety Management, Worksite Safety.

Shining a Light on Ventilation Systems and Surveys in the Electric Power Industry

Written by Connie L. Muncy, CIH, CUSP, MS, REM on . Posted in Safety Management, Worksite Safety.

Marking a Safety Milestone at Silicon Valley Power

Written by Damon Beck on . Posted in Safety Management, Worksite Safety.

Using Thermography for Underground Worker Safety

Written by Peter Tyschenko and Michael Meathe on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Addressing Common Fall Protection Questions and Concerns

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: OSHA Record-Keeping Requirements

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

April 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A.

Frontline Fundamentals: Risk Tolerance

Written by David McPeak, CUSP, CIT, CHST, CSP, CSSM on . Posted in Safety Management, Leadership Development, Worksite Safety, Frontline Fundamentals.

The Silent Secret About Successful Safety Communication

Written by Mark J. Steinhofer, CHST, CSP, CUSP on . Posted in Safety Management, Leadership Development.

Equipotential Grounding: Lessons Learned in the Field

Written by Dwight Miller, CLCP, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Understanding and Preventing Lower Back Pain in the Electric Utility Industry

Written by Dr. Andrew Murro, DC, DABCO on . Posted in Safety Management, Worksite Safety.

Maximizing Your Arc-Rated Gear

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: The New Walking-Working Surfaces Final Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Inspection, Maintenance and Fall Protection Guidance for Bucket Truck Use

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience, Equipment Operations.

February 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Leadership Development, Worksite Safety, Q & A, Equipment Operations.

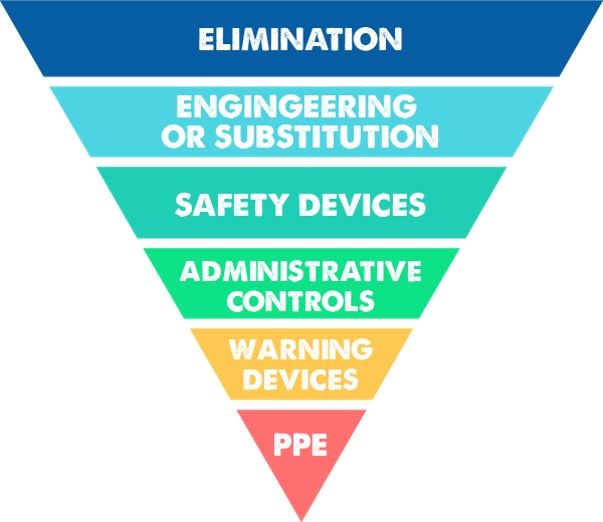

Frontline Fundamentals: Controlling Hazards

Written by David McPeak, CUSP, CIT, CHST, CSP, CSSM on . Posted in Safety Management, Leadership Development, Frontline Fundamentals.

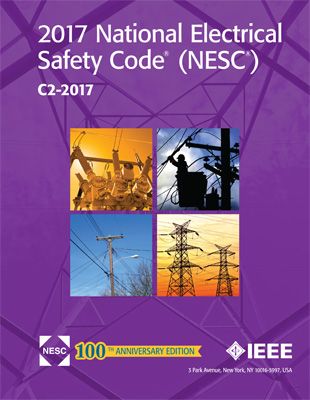

New Updates to the National Electrical Safety Code

Written by Sam Stonerock on . Posted in Safety Management, Worksite Safety.

Creating a Safe Driving Culture

Written by Eduardo Suarez on . Posted in Safety Management, Equipment Operations.

Emergency Preparedness for Remote Winter Work Locations

Written by Todd Horning on . Posted in Safety Management, Worksite Safety.

Rope Access for Live-Line Work

Written by Thomas Penner on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Train the Trainer 101: Understanding Canine Behavior for the Protection of Utility Workers: Part Two

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: Switching and Working on UD Systems

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience, Equipment Operations.

December 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations, Grounding.

Safety Best Practices for Outage Season

Written by Jordan Hollingsworth, CHST, CSP, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Assimilating Short-Service Employees Into Your Safety Culture

Written by Phillip Ragain on . Posted in Safety Management, Leadership Development, Worksite Safety.

Does Your Company Have an Effective Safety Management System?

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management, Leadership Development.

Underground Electrical Vaults: Safety Concerns and Controls

Written by Chris Grajek, CRSP, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Understanding Canine Behavior for the Protection of Utility Workers

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Voice of Experience: OSHA’s MAD Changes and a Missed Opportunity

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

October 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Equipment Operations.

Optimizing Your Safety Observation Program

Written by Thomas Arnold, CSP, CUSP on . Posted in Safety Management, Leadership Development.

The Causes and Prevention of Shoulder Injuries in the Electric Distribution Field

Written by Dr. Andrew Murro, DC, DABCO on . Posted in Safety Management, Worksite Safety.

The Road to an Innovative, Award-Winning Safety Program

Written by Brad Stout and Jesse Gibbon on . Posted in Safety Management, Leadership Development, Worksite Safety.