Inspecting the Fifth Wire: Winning the War on Lineworker Suicide

Lineworkers confront daily risks many can’t imagine – arc flashes, falls, electrocutions and more. Yet there’s a silent, insidious threat currently claiming more lives in the electric utility industry than any physical injury.

We’re talking about suicide.

Safety professionals dedicate their careers to mitigating risk and preventing harm, understanding that serious injuries and fatalities devastate lives and ripple through the workforce. But what if the most devastating injury of all is one largely overlooked in traditional safety programs?

Industry employers already deliver traditional safety training to employees and outfit them with personal protective equipment as their last line of defense against harm. These companies aren’t waiting f…

When the System Isn’t Enough: How to Create Personal Motivation That Saves Lives

Author’s Note: In this article – the first in a five-part series – we explore the notion of accepting 100% accountability for our safety at work, just as we do at home. This is an act of self-preservation. The hope is that management’s safety focus will overlap with our own preparation. We want as much overlap as possible.

The next article will address mental preparation, which is different than mental health. It’s a targeted focus to reduce risk of serious injuries and fatalities by improving our ability to remain self-aware and vigilant. We must keep our heads in the game.

When you’ve experienced as much loss as I have, safety becomes more than policy – it becomes a personal mission.

During the 31 years I worked for a large utility, I wi…

Advancing Safety Through Total Well-Being: Practical Tips and Ideas for Utility Leaders

Over the past 50 years, the electric utility industry has developed and implemented robust engineering controls, detailed work procedures and focused training to reduce injury and fatality rates among workers. However, the total well-being of the worker is another critical safety factor that utility organizations often don’t address.

Well-being encompasses physical health as well as mental, emotional and social dimensions that can significantly influence an individual’s capacity to make sound decisions, maintain situational awareness and successfully mitigate risks. Workers bring their whole selves to the job, which includes their stress, fatigue and other personal challenges. We leave serious gaps in our safety systems when we fail to acc…

Built In, Not Bolted On: Using Safety to Drive Operational Excellence

Employers in the electric utility industry are currently working on initiatives in various areas of their businesses, including safety, quality, production, leadership, and human and organizational performance (HOP). These are important programs, but it’s unlikely they’ll fully achieve their intended objectives if employees don’t have a firm grasp on how these various aspects of work impact one another – and the ideal order in which they should be addressed.

As someone who has spent a great deal of time studying HOP and teaching its principles to others, I understand that part of the philosophy is building an organizational system that enables employees to complete their work using processes that make sense to them, are easy to follow and…

Making the Safety Connection: The Impact of Total Well-Being in the Workplace

Utility workers perform essential tasks that touch millions of lives every day. The critical nature of the services they provide coupled with the perilous nature of their tasks exposes these workers to life-threatening hazards. This is why the industry highly values and prioritizes safety.

Many utility companies operating today have made significant strides in improving their safety culture. Critical risk management programs and a human performance mindset have become increasingly common as organizational leaders more fully understand the link between human behavior and risk. These companies have moved beyond the traditional safety model that primarily focuses on accident prevention, opting instead to embrace risk reduction strategies.

Use…

The Roadmap to Gaining Senior Leader Buy-In for Safety Initiatives

| Sharon Lipinski, Wesley L. Wheeler, SMS, CESCP, MSP, and Keith Wheeler | Safety Management, Leadership Development

In a recent survey we conducted, 97% of safety professionals who responded confirmed that gaining senior leader buy-in for their safety programs was either very important or extremely important to them.

This research project was a joint effort between the National Electrical Contractors Association, HR Resources of the Carolinas LLC and Habit Mastery Consulting, with the purpose of discovering the secrets to gaining greater senior leadership support for safety initiatives. Our research included surveying 128 safety professionals and conducting in-depth interviews with 15 deeply experienced safety professionals.

We revealed our research results at the October 2024 iP Utility Safety Conference & Expo in Allen, Texas, sharing with attende…

An Inextricable Link: The Safety Benefits of Holistic Wellness in the Workplace

There is an inextricable link between employee safety and mental and physical wellness that is often overlooked. Taking a holistic view of your employees includes looking wholly at each person to better understand and address their mental and physical health challenges and related distractions that can affect their personal safety and the safety of others.

Additionally, demonstrating you care about your employees’ well-being can translate into improved morale, engagement, productivity, and recruitment and retention.

At its foundation, your employee safety program should be viewed as an act of caring about your employees. However, our safety focus can often be siloed. It’s time to break through the silos and take a more comprehensive look a…

The Transformative Impact of Training for Frontline Managers

Frontline managers are crucial because they bridge organizational goals and frontline employees. They significantly influence workplace dynamics and performance outcomes. In this context, my company surveyed 110 safety professionals and interviewed 10 safety professionals across various industries – including construction, utility, wind energy, public works and manufacturing – to gain insights into the current state of frontline leadership skill development within organizations.

Our research reveals that the significance of frontline leadership skills cannot be overstated, as highlighted by this poignant quote from one construction company’s safety director: “We either have somebody who knows how to manage, who sets an example, who sees a…

Getting to the Heart of At-Risk Behaviors with Facilitative Learning

In a recent workshop with a client in southeast Louisiana, a breakout session reached a tipping point. The rhythmic flow of dialogue among the seven supervisors in the group found an unscripted but purposeful path of its own. The task given to the group involved identifying at-risk behaviors or shortcuts likely to occur in their work environment. Participants were also asked to discuss motives for the identified behaviors and strategies for shifting perspectives regarding them. The intent of the three-part exercise, which was deliberately constructed to achieve the resulting outcome, was to pull information from the collective experiences of those in the session needed to improve operational safety. My role in the process wasn’t to instruc…

ESG: Health and Safety Obstacle or Opportunity?

Over the past few years, much has been written and discussed about the role of environmental, social and governance, commonly referred to as ESG. Investors and customers are increasingly applying these nonfinancial factors as part of their analysis process to identify material risks and growth opportunities in the companies they decide to invest in. According to research from the Weinreb Group, in publicly held U.S. companies, the position described as chief sustainability officer has grown from 29 such officers in 2011 to 183 in 2023 (see https://weinrebgroup.com/2023-cso-report-press-release/). These are roles that typically sit in the C-suite of a company and have direct strategic decision-making responsibilities.

Many health and safety…

Pattern Disruption: Don’t Start with ‘Why’

In the northern latitudes, Mother Nature is deeply vested in a cycle of pattern disruption. The four seasons change the ecosystems and habitats. As the seasons shift in New York, the lake that I live on moves from a warm thermocline with colder layers on the bottom and warmer water on top to the opposite. In the coldest months, the top of the lake freezes entirely. The ground freezes, too, while the monarch butterflies leave and many of the birds fly south.

But even those pattern disruptions – the four seasons – become a rhythm, an expected ritual during which we trade lawnmowers for snowblowers and put away the outdoor furniture, only to reverse those actions when the weather becomes warm once again.

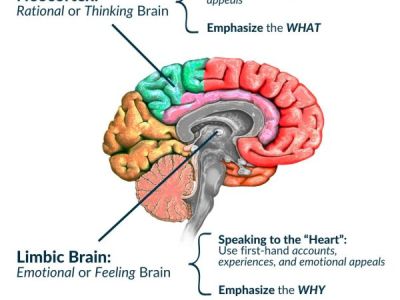

You may already know that the human br…

Nurturing Strong Leadership: An Approach to Professional Development in Skilled Trades

| Nathan Boutwell, M.Eng., CSP, SMS, CIT, CUSP, and Mike Starner, CUSP, CHST | Leadership Development

Strong leadership is essential for the success and well-being of a company. Effective leaders play a vital role in setting the course, motivating employees, fostering a positive work culture and making critical decisions that steer the organization toward its goals.

In our industry, leaders face significant challenges due to substantial growth, an aging workforce and concerns about the impact of both on operations. The need for professional development is a crucial item for workers in the skilled trades who will assume leadership roles. This development is necessary to help the next generation of leaders attain safe, reliable and fiscally sound operations.

Two Clear Opinions The best path to leadership in utility operations has been debate…

Tip of the Spear: A Tactical Approach to Safety Leadership

Leadership is defined as the action of leading a group or organization; it’s a verb. It’s also a skill that is extremely fluid. Leadership style can change depending on the person and the situation, but all effective leaders have some common qualities. When I developed the list below, I initially came up with 68 possible qualities, and while I know each of them has some merit, I eventually narrowed down the list to these 16 qualities that I believe are nonnegotiable.

1. Ability to effectively communicate 2. Ability to influence 3. Ability to inspire 4. Respect and trust (gives and earns) 5. Humility/no ego 6. Willingness to learn/continuous improvement 7. Master of delegation/empowers others 8. Honest/has integrity/is ethical 9. Flexible/a…

Overcoming the Illusion of Safety

There are striking similarities in how we respond to incidents, injuries and fatalities in our industry. Safety stand-downs are held. Utilities and contractors conduct incident investigations that are typically wrapped up with action items that need to be handled.

But consider this: Is everything we do in the wake of an incident truly effective in preventing future incidents? Let’s take it one step further. Are all the things we’re doing on a daily basis helping to ensure employee safety, or do we sometimes simply check a box, satisfy a requirement and tell ourselves we’re making the job safer for our workers?

My objective in writing this article is to take a hard look at some of the tactics we are currently using in the name of safety. I…

Gauges: How Do You Measure Safety?

The small utility had just lost two journeymen linemen to contractors, and they needed replacements who could hit the ground running. So, the company held some interviews and hired two seasoned journeymen.

Beyond Behavior-Based Safety: Why Traditional Safety Practices are No Longer Enough

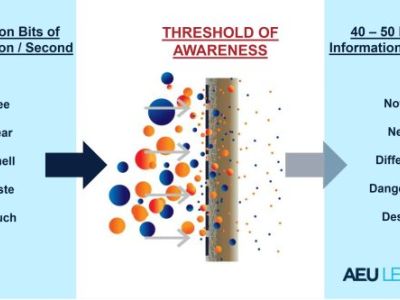

Traditional safety management practices are built on the assumption that human behavior is rational and occurs primarily through conscious decision-making. Nothing could be further from the truth. We are, in fact, irrational by nature, creatures of habit and deeply influenced by past experiences. To create the next step change in the practice of occupational safety, we must revisit existing paradigms defining it, revise them to better align with research emerging from advancements in neuroscience, and adapt to practice realigned strategies of an affective nature.

Irrational by Nature

In 2016, a municipality in western Virginia experienced a fatality when a maintenance worker entered a confined space containing lethal atmospheric conditions…

Using a Learning Management System to Augment Lineworker Training

“You can’t learn how to climb a pole by looking at a computer screen.”

That’s a sentence that has been repeatedly used in our industry to discredit web-based learning. And it’s true; in any skilled trade, neither distance learning nor classroom work alone can replace the skills and confidence gained from practicing tasks and building up muscle memory in the field. But does that mean there’s no place for distance learning? Absolutely not. When properly used to augment a field skills training program, online training can speed the development of skills, make your training program more efficient and keep your crews in the field longer.

Three Different Approaches

In 1984, educational psychologist Benjamin Bloom performed a study of three diff…

Does Positive Feedback Improve Safety?

Our client is an international utility company with more than 10,000 employees that provides electric and natural gas to 20 million U.S. customers. Their vision is to achieve a generative safety culture in which both employees and leaders are actively engaged. Characteristics of a generative safety culture include proactively resolving issues, focusing on leading indicators, and welcoming bad news as an opportunity for improvement, not for implementing discipline.

The company is well on their way to that destination, and it’s due in no small part to their employees’ dedication to their jobs, the training they’ve completed to excel in their work and their passion for wanting to create one of the best safety cultures in the utility industry.

‘But I Don’t Wanna’: 6 Sources of Employee Resistance

“I forgot.” “I don’t want to.” “It’s not that serious.” “It won’t happen to me.”

If your employees are forgetting, ignoring, pushing back against or actively resisting the protections you’ve put in place to ensure their safety, then you know how frustrating it can be to get them to follow the rules.

Crafting a safety initiative so that you end up with employees who want to follow your safety procedures depends on addressing the driving causes of their resistance. Following are six sources of potential resistance and strategies you can use to help overcome each one.

They don’t know.

The source of resistance could be a simple knowledge problem (i.e., they don’t know what they need to do). If employees are new to the workforce, the industr…

From My Bookshelf to Yours: ‘The Success Principles’

During the research and writing process for my new book – “Frontline Leadership: The Hurdle,” published by Utility Business Media Inc. – I read a lot of books, and I want to share some highlights from a few of my favorites. This article will focus on “The Success Principles: How to Get from Where You Are to Where You Want to Be” by Jack Canfield. I hope you find this article useful, and I also hope it inspires you to read both “The Success Principles” and my book as part of your continuing personal and professional development.

To highlight how much I believe in this book and want to encourage you to read it, I completed the program to become a Canfield Certified Trainer in the Success Principles after reading it once and being exposed to…