Tag: Safety Management

2013 USOLN Safety Award Winners Announced

Written by Kate Wade on . Posted in Safety Management, Leadership Development.

What OSHA’s Proposed Silica Rule Means to You

Written by Matt Edmonds, CUSP, CHST, CET on . Posted in Safety Management, Worksite Safety.

The Power of an Effective Field Observation Program

Written by Lee Marchessault, CUSP on . Posted in Safety Management.

Voice of Experience: The Globally Harmonized System is Here

Written by Danny Raines, CUSP on . Posted in Safety Management.

Safety Management During Change

Written by Claudia Hendricks on . Posted in Safety Management.

Transitioning to FR Clothing

Written by Jim Boyd, CUSP on . Posted in Safety Management.

Train the Trainer 101: Why You Need More than 1910 and 1926

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

Ergonomics for Lineworkers

Written by Steve Hedden, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Live-Line Tool Maintenance Program

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

The Authority to Stop Work

Written by Bart Castle on . Posted in Safety Management.

Foundation Drilling Safety: The Aldridge Electric Story of Success

Written by Gary Coleman, CHST, CSP, CUSP, OHST, STSC on . Posted in Safety Management.

Voice of Experience: Training for the Qualified Employee

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Voice of Experience: The Cost of Business

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Train the Trainer 101: Arc Hazard Protection

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

Voice of Experience: The Definition of Personal Protective Equipment

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Are You Prepared for the Next Generation of Lineworkers?

Written by Emily Wilkins, CSA, CUSP, and Ryan Schenk on . Posted in Safety Management.

Voice of Experience: Are You Ready for the Big Storm?

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Raising the Bar, Lowering the EMR

Written by Jesse Hardy, CSP, CIT, CUSP on . Posted in Safety Management.

Voice of Experience: FMCSR Compliance: Driver Qualification Files

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience.

Performance Improvement: Barriers to Events

Written by Kathy Ellsworth, CUSP on . Posted in Safety Management.

Safety and Human Performance: You Can’t Have One Without the Other

Written by David W. Bowman on . Posted in Safety Management.

Formal vs. On-the-Job Training

Written by Rick Tobey, CUSP on . Posted in Safety Management.

How S.A.F.E.T.Y. Brought Bluebonnet Through the Fires

Written by Emily Wilkins, CSA, CUSP on . Posted in Safety Management.

Strategic Safety Partners

Written by ET&D Strategic Partnership Task Team IV on . Posted in Safety Management.

The Intersect: A Practical Guide to Work-Site Hazard Analysis

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

Safety Rules and Work Practices: Why Don’t They Match Up?

Written by Jeremy Adcock and Pam Tompkins, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Hearing Conservation: An Interesting Challenge

Written by Gretchen Erga on . Posted in Safety Management.

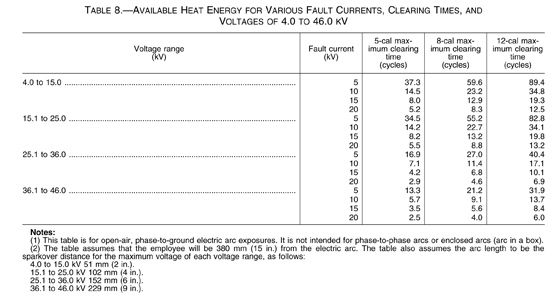

Arc Flash Exposure Revisited: NESC 2012 Part 4 Update

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

Safety Circuitry: The Power in the Brain

Written by Michelle Brown on . Posted in Safety Management, Leadership Development.

What’s Your Seat Belt IQ?

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

Competition for a Cause

Written by Kimberlee Craig on . Posted in Safety Management.

Employee Training: How Hard Can It Be?

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

Challenges & Successes

Written by William Bosch on . Posted in Safety Management.

Behavior Safety: A Safety Program’s Missing Link

Written by Michael S. Haro, Ph.D., CBSS on . Posted in Safety Management.

Northeast Utilities Takes Safety Off-Road

Written by Bruce Elfstrom on . Posted in Safety Management.

A92.2: The 2009 Standard

Written by Seth Skydel on . Posted in Safety Management, Equipment Operations.

Procedure for Reducing Injuries

Written by Tyrone Tonkinson, Ph.D., P.E. on . Posted in Safety Management.

Crane & Derrick Compliance

Written by Kate Wade on . Posted in Safety Management, Equipment Operations.

Solid Footing

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

LOTO vs. Switching and Tagging

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

Is Your Company Ready for the Next Disaster?

Written by Tommie Jones on . Posted in Safety Management.

Best Practices

Written by Matt Dell on . Posted in Safety Management.

Error-Free Performance: Part II

Written by John Boyle on . Posted in Safety Management, Leadership Development, Tailgate Topics.

People Focused Safety

Written by Lee Marchessault, CUSP on . Posted in Safety Management.

Error-Free Performance

Written by John Boyle on . Posted in Safety Management, Leadership Development, Tailgate Topics.

Confused About Arc Flash Compliance?

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

A FULL Commitment

Written by Patricia Seeley, CPE on . Posted in Safety Management, Worksite Safety.

NESC-2012-Part 4: Summary of Change Proposals

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

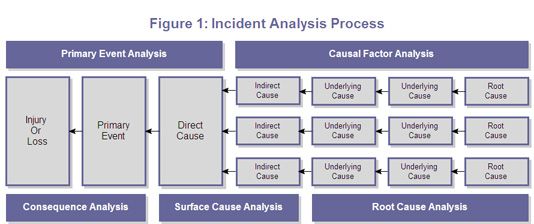

Root Cause Analysis

Written by Donald F. Fritz, CSP, CSHM on . Posted in Safety Management.

Soil Resistivity Testing & Grounding System Design: Part II of II

Written by John Howard on . Posted in Safety Management.

Huge Steps

Written by Terrell A. Davis on . Posted in Safety Management, Equipment Operations.

Making Safety a Core Value

Written by Carla Housh on . Posted in Safety Management.

Soil Resistivity Testing & Grounding System Design: Part I of II

Written by John Howard on . Posted in Safety Management.

Incident Analysis

Written by Donald F. Fritz, CSP, CSHM on . Posted in Safety Management.

Moving from Operations into Safety or Training

Written by Bart Castle on . Posted in Safety Management.

What’s in a Number?

Written by Donald Brignac on . Posted in Safety Management.

Strategies for Safety in the Wind Industry

Written by Kate Wade on . Posted in Safety Management, Worksite Safety.

Keeping Things Safe in the Field and the Office

Written by John Boyle on . Posted in Safety Management, Tailgate Topics.

Safety Culture Success

Written by Kate Wade on . Posted in Safety Management.

Managing Safety

Written by Carl Griffith on . Posted in Safety Management.

Passion for Safety

Written by Steve Owen on . Posted in Safety Management.

Managing Safety Rule Violations

Written by Tyrone Tonkinson, Ph.D., P.E. on . Posted in Safety Management.

NESC 2007 FLAME RESISTANT CLOTHING

Written by Hugh Hoagland on . Posted in Safety Management.

Bridging Communication Gaps

Written by Parrish Taylor on . Posted in Safety Management.

Dreams Can Become Reality: SDG&E Flex Center

Written by Seth Skydel on . Posted in Safety Management.

Making Safe Choices

Written by Rick Tobey, CUSP on . Posted in Safety Management.

NESC-2007 Update

Written by Pam Tompkins, CSP, CUSP on . Posted in Safety Management.

Dissecting an OSHA Inspection

Written by Michael Beckel on . Posted in Safety Management.

Dramatic Results

Written by Seth Skydel on . Posted in Safety Management.

Keeping the ‘Fighter Pilots’ of Your Company Safe

Written by Jeff "Odie" Espenship on . Posted in Safety Management, Leadership Development.

Taking Safety to the Next Level

Written by Nancy St. Hilaire, MS on . Posted in Safety Management, Leadership Development.

Leadership Influencing the Culture

Written by Don Groover, CIH, CSP on . Posted in Safety Management, Leadership Development.

What It Takes to be a Safety and Compliance Leader

Written by Ken Flechler, CUSA on . Posted in Safety Management, Leadership Development.

Injury Free Change

Written by Carl Potter, CSP on . Posted in Safety Management, Leadership Development.

Eliminating Excuses

Written by Carl Potter, CSP on . Posted in Safety Management.

Lessons Learned, Successful Implementation of Behavioral Safety Coaching

Written by Dr. E. Scott Geller, PhD on . Posted in Safety Management, Leadership Development.