Tag: ppe

Arc Rating Standards for Personal Protective Equipment

Written by Zarheer Jooma, P.E., and Hugh Hoagland on . Posted in Worksite Safety.

Understanding, Selecting and Caring for FR/AR Clothing

Written by Derek Sang, CSHEP, QSSP on . Posted in Safety Management.

The Hard Hat Celebrates 100 Years

Written by Stacey Simmons on . Posted in Worksite Safety.

Rubber Insulating Sleeves and Arc Flash Protection

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management.

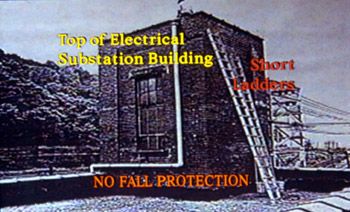

Scenario-Based Fall Protection Solutions

Written by Rob D. Adams, CLCP, CUSP on . Posted in Safety Management.

Secondary FR Garments: Practical Solutions for Protection

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management.

Making Sense of Protection Requirements for Open-Air Arc Flash Hazards

Written by Lee Marchessault, CUSP on . Posted in Safety Management, Worksite Safety.

Injury Risks Associated with Climbing in the Wind Energy Generation Industry

Written by Naira Campbell-Kyureghyan, Ph.D. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Training and Verification Requirements for the Safety of Electric Utility Workers

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

Train the Trainer 101: Addressing Common Fall Protection Questions and Concerns

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

April 2017 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A.

Maximizing Your Arc-Rated Gear

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: The New Walking-Working Surfaces Final Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Train the Trainer 101.

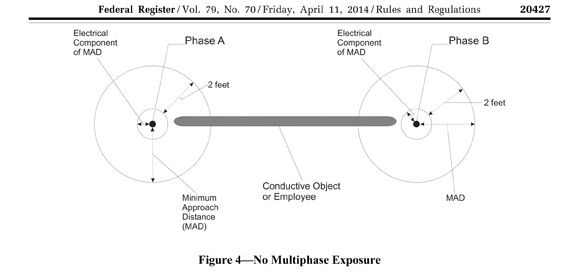

Voice of Experience: OSHA’s MAD Changes and a Missed Opportunity

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

Best Practices for Arc-Rated Clothing Programs

Written by Hugh Hoagland on . Posted in Safety Management, Worksite Safety.

Voice of Experience: Hand and Skin Protection for Electric Utility Workers

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

February 2016 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Q & A, Grounding.

Voice of Experience: PPE Regulatory and Consensus Standard Requirements

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

Train the Trainer 101: Practical MAD and Arc Flash Protection

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

N95 Filtering Face Pieces: Where Does Your Organization Stand?

Written by Jarred O'Dell, CSP, CUSP on . Posted in Safety Management, Worksite Safety.

Arc Flash Mitigating Technologies and the OSHA Final Rule

Written by Samy Faried on . Posted in Safety Management, Worksite Safety.

How to Navigate the FR Clothing Marketplace

Written by Derek Sang, CSHEP, QSSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Back to Basics: ‘Gentlemen, This is a Football’

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: Fundamentals of Underground Padmount Transformers

Written by Danny Raines, CUSP on . Posted in Safety Management, Voice of Experience, Equipment Operations, Grounding.

June 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

The Roller-Coaster Life Cycle of IEEE 1307

Written by Ed Hunt, CUSP on . Posted in Safety Management, Worksite Safety.

The Importance of Matching Evidence Marks in Accident Investigations

Written by Allen L. Clapp, P.E. on . Posted in Safety Management, Worksite Safety.

Recent PPE Changes and 2015 Trends

Written by Hugh Hoagland and Stacy Klausing, M.S. on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Addressing Anchorages

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: The Importance of Job Briefings

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

February 2015 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Train the Trainer 101: Substation Entry Policies

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

December 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Grounding.

Voice of Experience: Flame-Resistant Apparel is Now PPE

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

October 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety, Equipment Operations.

Train the Trainer 101: Fall Protection and the New Rule

Written by Jim Vaughn, CUSP on . Posted in Safety Management, Worksite Safety.

Voice of Experience: OSHA Eye and Face Protection Standards

Written by Danny Raines, CUSP on . Posted in Safety Management, Worksite Safety, Voice of Experience.

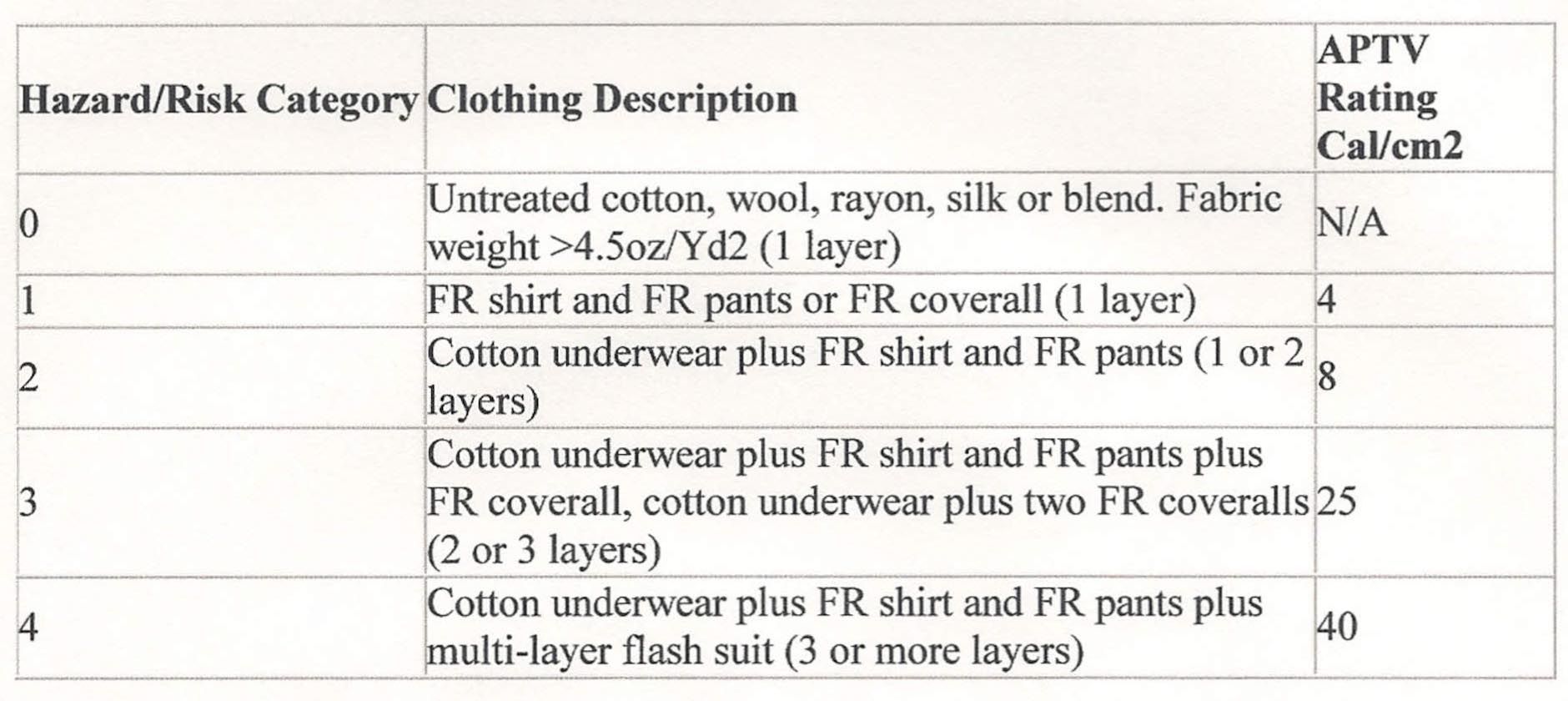

NFPA 70E Arc Flash Protection for Nonexempt Industry Workers

Written by Jim Phillips, P.E. on . Posted in Safety Management, Worksite Safety.

June 2014 Q&A

Written by Jim Vaughn, CUSP on . Posted in Worksite Safety.

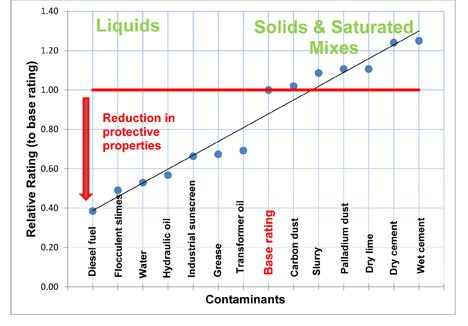

Addressing Comfort and Contamination in Arc-Rated Clothing

Written by Hugh Hoagland and Mikhail Golovkov on . Posted in Safety Management.

Transitioning to FR Clothing

Written by Jim Boyd, CUSP on . Posted in Safety Management.

Keys to Evaluating and Comparing Arc-Rated and Flame-Resistant Fabrics

Written by Scott Margolin on . Posted in Uncategorized.

FR Layering Techniques

Written by Will Vereen on . Posted in Uncategorized.

Back to the Basics: PPE 101

Written by Heath J. Haukland, CUSP on . Posted in Uncategorized.

Five PPE Safety Challenges

Written by Hugh Hoagland on . Posted in Uncategorized.

Hand Protection

Written by John Boyle on . Posted in Tailgate Topics.

Solid Footing

Written by Jim Vaughn, CUSP on . Posted in Safety Management.

What Does NFPA 70E Mean To You?

Written by John Boyle on . Posted in Tailgate Topics.

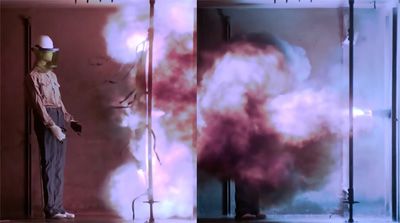

Arc Suppression Blanket Installation

Written by Victor L. Petrovic, Ph.D. on . Posted in Worksite Safety.

Arc Flash – Are You in Compliance?

Written by Pam Tompkins, CSP, CUSP on . Posted in Worksite Safety, Archived Posts.

PPE The Last Line of Defense

Written by Rick Tobey, CUSP on . Posted in Worksite Safety.

Free Climbing vs. Safer Climbing

Written by Carla Housh on . Posted in Worksite Safety.

Effective Fall Protection for Utility Workers

Written by Kate Wade on . Posted in Worksite Safety.

Top Five PPE Mistakes

Written by Hugh Hoagland on . Posted in Worksite Safety.

The Burning Question

Written by Scott Margolin on . Posted in Worksite Safety.

Fall Protection by the Numbers

Written by Lee Marchessault, CUSP on . Posted in Worksite Safety.