Tag: Tailgate Topics

Wood Pole Inspection and Testing

Written by Phillip B. McGee, CUSP on . Posted in Tailgate Topics.

A Key to Safety Performance Improvement

Written by Nick Davey on . Posted in Uncategorized.

Are You Your Brother’s Keeper?

Written by Steve Hedden, CUSP on . Posted in Uncategorized.

Improving Safety Through Communication

Written by Michael J. Getman, CUSP, MBA on . Posted in Uncategorized.

Electrical Capacitors in AC Circuits

Written by John Morton, CUSP on . Posted in Tailgate Topics.

Using Best Practices to Drive Safety Culture

Written by Tim D. Self, CUSP on . Posted in Uncategorized.

Traffic Safety for Lineworkers

Written by Mike Caro, CUSP on . Posted in Tailgate Topics.

Trenching and Excavations: Considerations for the Competent Person

Written by Charles R. Southerland, CSC, CUSP on . Posted in Tailgate Topics.

Emergency Action Plans for Remote Locations

Written by Gary Coleman, CHST, CSP, CUSP, OHST, STSC on . Posted in Uncategorized.

Multitasking vs. Switch-Tasking: What’s the Difference?

Written by David McPeak, CUSP, CIT, CHST, CSP, CSSM on . Posted in Uncategorized.

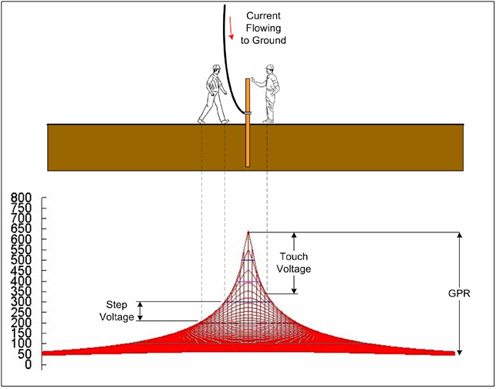

Understanding Step and Touch Potential

Written by John Boyle on . Posted in Tailgate Topics.

OSHA Job Briefing Basics

Written by Will Schnyer on . Posted in Uncategorized.

Bighorn Sheep vs. Lineworkers: What’s the Difference?

Written by Jim Vaughn, CUSP on . Posted in Uncategorized.

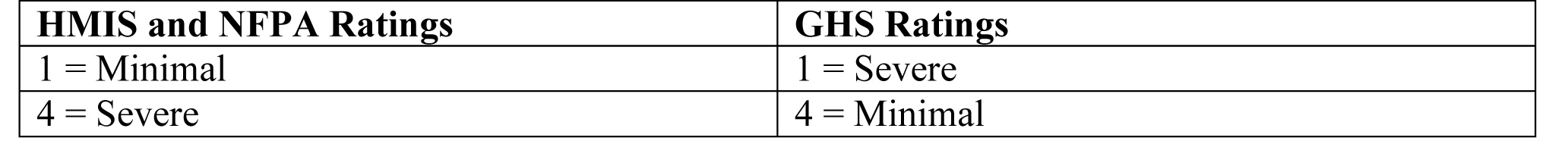

The Globally Harmonized System for Classifying and Labeling Chemicals

Written by Charles R. Southerland, CSC, CUSP on . Posted in Uncategorized.

Working Safely with Chain Saws

Written by John Boyle on . Posted in Tailgate Topics.

Soil Classification and Excavation Safety

Written by Lester Apley, CHST, CUSP on . Posted in Tailgate Topics.

Live-Line Work on the Jersey Shore

Written by Will Schnyer on . Posted in Tailgate Topics.

Managing Cold Stress

Written by John Boyle on . Posted in Tailgate Topics.

Care and Maintenance of Climbers

Written by John Boyle on . Posted in Tailgate Topics.

Detecting Shock Hazards at Transmission Line Work Sites

Written by Gary Zevenbergen on . Posted in Worksite Safety, Tailgate Topics.

Care of Portable Ladders

Written by John Boyle on . Posted in Tailgate Topics.

A Mirror: Your Most Important PPE

Written by David McPeak, CUSP, CIT, CHST, CSP, CSSM on . Posted in Tailgate Topics.

The Value of Personal Protective Equipment

Written by Will Schnyer on . Posted in Tailgate Topics.

Safe Digging – Get the 411 on 811

Written by John Boyle and Kurt Kollwelter on . Posted in Tailgate Topics.

Combating Overuse and Overexertion Injuries

Written by John Boyle on . Posted in Tailgate Topics.

Safe Use of Portable Electric Tools, Cords and Generators

Written by John Boyle on . Posted in Tailgate Topics.

Communication: The Key to Great Safety

Written by John Boyle on . Posted in Tailgate Topics.

Safety Leadership in a Written Pre-Job Briefing

Written by Tim D. Self, CUSP on . Posted in Tailgate Topics.

Basic Qualifications of Employees

Written by Chuck Woodings, CUSP on . Posted in Tailgate Topics.

Felling of Trees Near Power Lines

Written by Will Schnyer on . Posted in Tailgate Topics.

No-Voltage Testing

Written by John Boyle on . Posted in Tailgate Topics.

Substation Safety

Written by John Boyle on . Posted in Tailgate Topics.

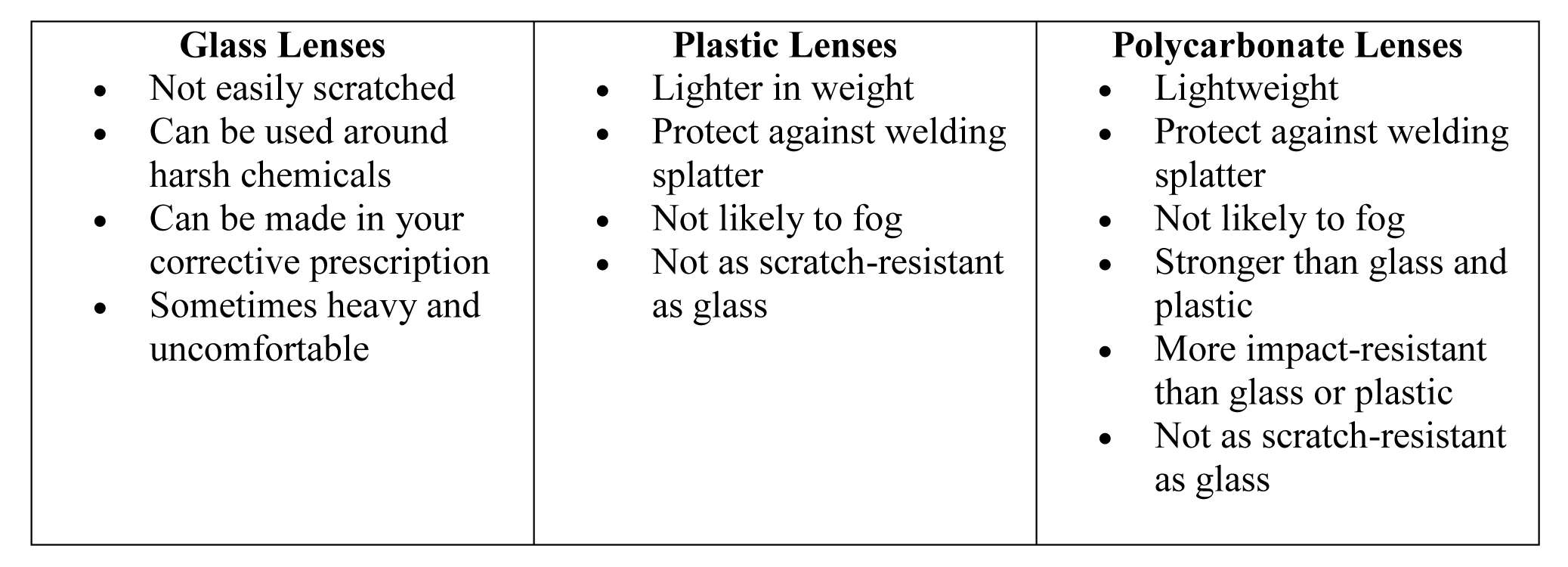

A Second Look at Safety Glasses

Written by John Boyle on . Posted in Tailgate Topics.

Equipment: Back to Basics

Written by John Boyle on . Posted in Tailgate Topics.

Live-Line Tool Use and Care

Written by Will Schnyer on . Posted in Tailgate Topics.

Taking Stock of Your Fall Protection Compliance

Written by Tim D. Self, CUSP on . Posted in Tailgate Topics.

Drop Zone Management: Expanding Our View of Line of Fire

Written by John Boyle on . Posted in Tailgate Topics.

High-Pressure Hydraulic Injection Injuries

Written by John Boyle and John Wisniewski on . Posted in Tailgate Topics.

Vehicle Operation Winter Readiness

Written by John Boyle on . Posted in Tailgate Topics.

Rubber Insulating Line Hose

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Hand Protection

Written by John Boyle on . Posted in Tailgate Topics.

Compressed Gas Cylinder Safety

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Preventing Employee Exposure to Pesticides

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Line of Fire

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Error-Free Performance: Part II

Written by John Boyle on . Posted in Safety Management, Leadership Development, Tailgate Topics.

Error-Free Performance

Written by John Boyle on . Posted in Safety Management, Leadership Development, Tailgate Topics.

Analyzing Safety and Hazards on the Job

Written by John Boyle on . Posted in Leadership Development, Tailgate Topics.

What Does NFPA 70E Mean To You?

Written by John Boyle on . Posted in Tailgate Topics.

How Good Are Your Tailgates?

Written by John Boyle on . Posted in Leadership Development, Tailgate Topics.

Aerial Lifts

Written by John Boyle on . Posted in Equipment Operations, Tailgate Topics.

Know the Signs and Symptoms of Heat-Related Illnesses

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Floodwater Hazards and Precautions

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Hidden Traps of Generator Use and Backfeed

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Stuck in the Mud

Written by John Boyle on . Posted in Worksite Safety, Equipment Operations, Tailgate Topics.

Machine Safety

Written by John Boyle on . Posted in Equipment Operations, Tailgate Topics.

Winter Safety Vehicle Checklist

Written by John Boyle on . Posted in Equipment Operations, Tailgate Topics.

Keeping Things Safe in the Field and the Office

Written by John Boyle on . Posted in Safety Management, Tailgate Topics.

Inspecting, Cleaning and Storing Live-Line Tools

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.

Inspection of Wooden Poles

Written by John Boyle on . Posted in Worksite Safety, Tailgate Topics.