Be the Light

“This little light of mine, I’m gonna let it shine, let it shine, let it shine, let it shine.”

Light. We literally cannot live without it.

In addition to sustaining life, light can be used in various other ways, including helping us to see clearly and sanitizing unsafe conditions. That sounds a lot like what safety is all about, which means that safety professionals need to be the light. With that in mind, let’s discuss how you can become a safety light – one that shines brightly.

Light is Revelatory When you lose something in the dark and then turn on a light, what you couldn’t see before becomes obvious. Put another way, what was always there can easily be found in the light.

The same is true with human factors, such as rushing, risk tol…

Verbal and Physical Triggers

Think before you act.

That may be the single best piece of timeless wisdom we ever receive, especially when it comes to safety. And while it’s a simple concept, it’s not always our natural response, potentially presenting difficulties during job execution and task performance.

Keeping in mind that safety tools are designed to give us time to think, focus our attention properly and help us maintain positive control of our tasks, we must identify actions and conditions that indicate the need for them. These actions and conditions are verbal and physical triggers that can be used as reminders to pause and ensure we have verified assumptions and implemented task-specific safety plans for the work being performed.

“Hold my beer and watch this!”…

Your Response Matters … A Lot

How you respond to other people and events matters. It matters a lot. Your responses – both as a leader and a member of the TEAM (Together Everyone Accomplishes More) – impact every part of your life, including culture, relationships and safety.

Let’s start with this: “Responding” is a task. To perform the task well, we need tools that give us time to think, help us focus our attention and assist us in controlling our work, emotions, risk tolerance and decision-making. Now, keeping in mind that good tools help us work better and great tools help us think better, we’re going to discuss a great tool that will help optimize our response to any event.

When discussing principle one (“Take 100% responsibility for your life”) in his book “The Suc…

Prioritize Safety Now So It Becomes a Value Before It’s Too Late

We typically excel at safety – after an incident. My question is, can we get it right before an incident occurs? And if so, how? Keeping in mind that you probably learned a stove could be hot by touching one as a child, let’s consider another question: Is it possible for us to develop safety-related values or are we doomed to learn the hard way?

Take a look through the events and incidents listed below. Understanding why those individuals now use human and organizational performance (HOP) tools (e.g., checking; verification; say it out loud; event + response = outcome; step-by-step place-keeping) – even if they don’t know HOP terminology – may provide insight into how much they inherently value safety, work methods and procedures.

A man wh…

The Good Shepherd

If you’re like me, you’ve only encountered sheep at a petting zoo, so here’s a fun fact about them: sheep have rectangular pupils. I included that to make sure you learn something today and to challenge us to explore other sheep characteristics and what we can learn from sheep-shepherd relationships. In doing so, we’ll use the C5 safety leadership model from the Incident Prevention Institute’s Frontline training program to establish what it means to be a good shepherd and then apply that understanding to enhance our roles as safety leaders.

Sheep and Shepherds Sheep are valuable assets that need protection. Because it’s easy for them to get lost or deviate, they require direction, feedback, and correction when they are off course. They mak…

Bad Attitudes and How to Handle Them

One of the questions I’m most frequently asked during leadership classes is how to handle people with bad attitudes. So, I’d like to take this opportunity to share some highlights from those discussions. I will remind you that leadership is much more of an art than a science. There is no perfect roadmap that shows us how to successfully work with every person in every scenario. I’ll also remind you that you get what you tolerate; while ignoring bad attitudes and hoping they’ll improve is technically a strategy, it’s probably not your best choice.

Your Circle of Control Let’s begin with some discussion about creating culture and developing relationships. The investments you make in these two activities are the starting point for everything…

Win and Win Again: The Blueprint for Repeating Safety Successes

The primary goal of safety is to prevent injuries. We achieve that goal in most cases, though our rare failures often overshadow our frequent successes. And while it’s essential to analyze failures and apply lessons learned, it’s equally if not more important to highlight and replicate our successes. So, let’s explore how to define success, reinforce success and, most critically, ensure repeated and continuous success.

Success Defined Success can be defined as desired behaviors achieving desired results – with extreme preference given to behaviors. From that definition, and in order from least to most desired, we get the following.

Incident: undesired behaviors with undesired results – someone doing something incorrectly that causes damage…

Make It Safe To …

A trainer, speaking to trainees at the start of class: “Welcome, class. You are encouraged to ask questions and participate. Remember, if you have a question, 15% to 20% of the class probably has the same question.”

A trainee, a few hours later: “I have a question.” The trainee then asks the trainer a question related to the material.

The trainer, after walking to the board, writing the trainee’s question down and then crossing it out: “I have already covered this, and I’m not wasting time going over it again. You need to pay attention.”

Trainee: “You said we should ask questions.”

Trainer: “That didn’t include stupid questions.”

Trainee: “You’re a liar.”

Trainer: “I’d rather be a liar than an idiot.”

Seventeen years after this real-life i…

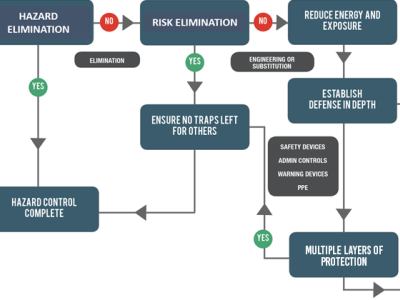

Preventing SIFs with Above-the-Line Work Planning and Execution

Are the things that hurt people the same as the things that kill people? Should safety focus on preventing serious injuries and fatalities (SIFs)? In this article, I’m not going to attempt to answer either of those questions. Instead, I’m going to do two other things. First, I’ll provide you with insights and resources that will help you answer the questions for yourself, and second, I’ll define above-the-line work planning and execution.

Let’s start with Herbert William Heinrich’s injury pyramid from the 1931 publication “Industrial Accident Prevention: A Scientific Approach.” Heinrich proposed a 1:29:300 ratio, often called Heinrich’s Law, which states that for a group of 330 similar accidents, 300 will produce no injury, 29 will cause m…

START Work Authority

Stop-work authority is crucial in our industry. Understand me when I say this: If people aren’t using stop-work authority, they don’t have that authority even if it’s promoted on a bulletin board somewhere.

With that said, I want to propose START (self, task, assess, reduce, thrive) work authority to reduce the number of times you’ll need to stop work. I admit this is a play on words and that what I am proposing is very similar to stop-work authority, but I want to challenge the norm of defining “fitness for duty” as someone being present at the work site and “work planning” as being limited to a singular job briefing at the start of the day. We can do that by exercising START work authority.

Self Safety starts with you. You cannot assume…

Receiving Feedback

Most leadership development programs talk about the vital skill of giving feedback, as they should. I hope you’ve been trained on coaching and feedback and that you practice and enhance those skills frequently.

But what about receiving feedback? That is another skill that can be learned, practiced and improved. And it’s a skill I don’t think we provide enough training on. I’ll propose it is difficult if not impossible to give feedback if you aren’t good at receiving it. So, let’s talk about how to practice and enhance the skill of receiving feedback.

Sources of Feedback Feedback is everywhere if we seek it out and are willing to receive it. Sources of feedback include yourself, other people, system responses and results. Your own assessmen…

Game-Planning for Safety

Given a relatively equal amount of talent on both sides, the sports TEAM (Together Everyone Accomplishes More) with the best game plan will likely win. Examining what champions – especially those that create dynasties – do well provides us with insight into achieving excellence in safety.

Job and Task Hazard Analyses Most champions excel at scouting. They understand the strengths, weaknesses and tendencies of their opponents so well that they can predict what they will do in certain situations. This is fantastic news for us because our opponents – hazards and risks – are quantifiable and predictable. Apart from hazards like animals, we know exactly how they will behave, which makes it simple to game-plan for success.

We do this by develop…

The Art of Safety – A New Hierarchy

Given the predictable nature of hazards, how and why do incidents occur? Think about this: If I know the winning numbers ahead of a lottery drawing, it’s simple for me to be 100% successful at winning the lottery money. So, if we know how hazards are going to act and how they cause harm, why aren’t we 100% successful at safety? It’s because we don’t fully grasp and utilize the Art of Safety, or how and why you must understand, lead, develop and protect people.

That’s why I wrote the book “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” and why I am focusing my 2023 Incident Prevention articles – and their corresponding free webinars – on the Art of Safety. In this article and its associat…

The Art of Safety – Unnormalizing Deviation

Given the predictable nature of hazards, how and why do incidents occur? Think about this: If I know the winning numbers ahead of a lottery drawing, it’s simple for me to be 100% successful at winning the lottery money. So, if we know how hazards are going to act and how they cause harm, why aren’t we 100% successful at safety? It’s because we don’t fully grasp and utilize the Art of Safety, or how and why you must understand, lead, develop and protect people.

That’s why I wrote the book “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” and why I am focusing my 2023 Incident Prevention articles – and their corresponding free webinars – on the Art of Safety. In this article and its associat…

The Art of Safety: Self-Reliance

Given the predictable nature of hazards, how and why do incidents occur? Think about this: If I know the winning numbers ahead of a lottery drawing, it’s simple for me to be 100% successful at winning the lottery money. So, if we know how hazards are going to act and how they cause harm, why aren’t we 100% successful at safety? It’s because we don’t fully grasp and utilize the Art of Safety, or how and why you must understand, lead, develop and protect people.

That’s why I wrote the book “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” and why I am focusing my 2023 Incident Prevention articles – and their corresponding free webinars – on the Art of Safety. So, let’s get started and discu…

The Art of Safety: Protect the Worker

Given the predictable nature of hazards, how and why do incidents occur? Think about this: If I know the winning numbers ahead of a lottery drawing, it’s simple for me to be 100% successful at winning the lottery money. So, if we know how hazards are going to act and how they cause harm, why aren’t we 100% successful at safety? It’s because we don’t fully grasp and utilize the Art of Safety, or how and why you must understand, lead, develop and protect people.

That’s why I wrote the book “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” and why I am focusing my 2023 Incident Prevention articles – and their corresponding free webinars – on the Art of Safety. So, let’s get started and discov…

The Art of Safety: Lead People, Not Robots

Given the predictable nature of hazards, how and why do incidents occur? Think about this: If I know the winning numbers ahead of a lottery drawing, it’s simple for me to be 100% successful at winning the lottery money. So, if we know how hazards are going to act and how they cause harm, why aren’t we 100% successful at safety? It’s because we don’t fully grasp and utilize the Art of Safety.

That’s why I wrote the book “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” and why I am focusing my 2023 Incident Prevention articles – and their corresponding free webinars – on the Art of Safety. So, let’s get started and discover how to effectively lead and protect people rather than managing rob…

The Art of Safety: C5 Leadership

C5 safety leaders care about their teams and focus on what they can do to prevent harm and encourage growth.

The Art of Safety is understanding, leading, developing and protecting people, including yourself. It’s how to lead safety and work safely. We excel at the science of safety, things like ergonomics, electrical theory and fall protection. I can calculate, for instance, gravity and acceleration during a fall and how much force would be involved in hitting a lower surface. I know electricity is going to take every path to ground, and I can use Ohm’s law to determine current, voltage and resistance. I understand why trenches collapse, and I can calculate soil weight. In other words, the science of safety allows us to quantify and predic…

From My Bookshelf to Yours: ‘Who Moved My Cheese?’

Not long ago, Utility Business Media Inc. published a book I wrote: “Frontline Leadership – The Hurdle.” During the research and writing process, I read a lot of books and want to share highlights from some of my favorites. This article will focus on the bestselling book “Who Moved My Cheese?: An A-Mazing Way to Deal with Change in Your Work and in Your Life” by Spencer Johnson, M.D. I hope you find the article useful, and I also hope it inspires you to read both “Who Moved My Cheese?” and my book as part of your continuing personal and professional development.

From My Bookshelf to Yours: ‘No Compromise’

Dang you, Ken Sheridan. I had a life and a job that I enjoyed, and I thought I had safety figured out. Then you wrote “No Compromise: The Truth About Workplace Safety & Business Success.” I couldn’t put it down, and worse yet, chapter four is so good I read it three times before I ever got to chapter five.

On top of that, I just published my second book – “Frontline Incident Prevention – The Hurdle: Innovative and Practical Insights on the Art of Safety” – which I was really excited to promote in this issue of Incident Prevention magazine. Because of you, I can’t do that; instead, I must talk about your book and share some of its wisdom with my readers. So again, dang you, Ken Sheridan.

Overview “No Compromise” really does tell the tru…