Incident Prevention Utility Safety Podcast

The place utility safety and operations professionals go to learn how to empower themselves and others in their organization on how to become even better safety professionals.

PODCASTS BY INTERVIEWER

Utility Safety Podcasts

Flight-Ready HEC Solutions

Buckingham offers flight-ready solutions for human external cargo (HEC) applications: the BuckFLIGHT HEC Harness (Non-Step In); Arc Tested Buck Access Tower Harness (Step In); and Arc Tested BuckTech Harness (Non-Step In).

Per FAA Policy Statement PS-AIR-27/29.865, ANSI Z359.11 full-body harnesses are now acceptable for use in HEC applications, providing an alternative to the harness requirements previously defined under FAA TSO-C167.

The BuckFLIGHT HEC Harness (64992) – developed collaboratively by experts who live and breathe safety, flight operations and on-structure work – sets a new standard for HEC performance. Key features include hi-vis webbing color that enhances visibility for pilots during HEC operations; an integrated RFID tag for inspection tracking; and a new HEC tagging system that includes a removable five-year HEC service-life label.

The 61992 Arc Tested Buck Access Tower Harness is the ultimate companion for both tower and fly work, providing exceptional suspension comfort during flight while maintaining the familiar fit and feel of a traditional lineman’s belt.

Lastly, the 68K966K6 Arc Tested BuckTech Harness takes safety and performance to the next level with the superior adaptability, comfort and performance required for both flight- and structure-based operations. https://buckinghammfg.com

Utility Strike Prevention System

Xwatch Safety Solutions, part of Hexagon, a leader in excavator safety systems, and RodRadar, developer of the field-proven Live Dig Radar (LDR), have announced the industry’s first safety-grade solution for preventing underground utility strikes. The integrated system automatically stops excavator bucket movement when subsurface utilities are detected during active excavation, making RodRadar’s Zero-Strike vision a reality.

RodRadar’s AI-driven LDR digging system uses the first-ever ground-penetrating radar embedded directly in an excavator bucket to detect underground utilities in real time, during excavation, without reliance on pre-project utility data. Through the RodRadar/Xwatch integration, LDR-detected utilities trigger an automatic bucket stop via Xwatch’s safety-grade hydraulic control system.

This integration represents a fundamental step in excavation safety. The approach is analogous to the automotive industry’s evolution from advanced driver assistance systems that merely warn drivers to autonomous emergency braking that actively prevents collisions. The integrated system takes direct action, delivering what RodRadar terms Stop-Before-Strike, while operators retain override capability. https://hexagon.com, https://rodradar.com

Davit Arm Systems

3M DBI-SALA Davit Arm Systems are designed for manhole and confined space entry/retrieval applications. These units are constructed of lightweight materials, including high-strength aluminum. The davit pivots for ease of rescue and has adjustment for overhead clearance restrictions. The lower base adjusts to fit most standard entries. Many other portable and fixed bases are available to suit any jobsite need. www.3m.com/3M/en_US/p/dc/v100869192/

Drill-Activated Load Binder

Durabilt Durbin has introduced the all-new DuraTorQ (DTQ) Series, a patent-pending torque drive load binder engineered to redefine efficiency in load securement. Designed for drill activation, the DTQ-12 is compatible with 1/2-inch to 3/8-inch chain, while the DTQ-38 is compatible with 3/8-inch to 5/16-inch chain, delivering fast, controlled tensioning with significantly reduced physical strain.

These binders shift manual force to power-assisted operation, dramatically cutting operator fatigue and shortening loading and unloading times. Each DTQ binder is 100% proof load tested and includes trace codes for enhanced product accountability and tracking. With a focus on productivity and consistency, the DuraTorQ Series allows crews to secure loads faster without sacrificing safety or performance. https://durabiltusa.com

MEWP Kits

Guardian’s new Mobile Elevated Work Platform (MEWP) Kits with leading-edge protection provide a complete, compliant fall protection solution designed specifically for MEWP operators. Each all-inclusive kit features a Guardian Full-Body Harness paired with the CR3-Edge Class 2 Self-Retracting Lifeline (SRL) and is conveniently packaged in a durable Carry Bag for easy transport and storage. Since MEWPs do not offer overhead anchorage, a Class 2 leading-edge-rated SRL is required to help ensure proper protection. The CR3-Edge connects directly to the MEWP anchor point, removing the weight of the device from the worker’s back and reducing fatigue during extended tasks at height. Many lifts include multiple anchorage locations, including mid-rail anchor points, allowing the SRL housing to remain secured to the structure of the lift while the user maintains continuous tie-off. With 10 feet of usable cable, the CR3-Edge provides enhanced mobility within lifts and supports efficient movement in warehouse and distribution environments. All Guardian Class 2 MEWP Kits are OSHA and ANSI compliant and engineered to keep operators safe, comfortable and productive at height. https://guardianfall.com/product/mewp-kit

Influencing Safety – Looking Upstream – The Secret to Stopping Incidents Before They Start – Bill Martin, CUSP

In this episode of the Influencing Safety podcast, Kate Wade and Bill Martin pull back the curtain on their creative process with a raw, “behind-the-scenes” brainstorming session. They explore the critical shift from reacting to downstream incidents to identifying the “upstream” conditions that create them. By discussing concepts like the “teaspoon fallacy,” psychological safety, and the importance of neurodiversity, they challenge the utility industry to move beyond comfortable data and embrace the uncomfortable curiosity required to save lives.

Key Takeaways

- Look Upstream for Solutions: Focusing only on the outcome of an incident is a downstream reaction; true prevention requires identifying the weak signals and root conditions—such as poor communication or high-pressure environments—that exist higher “up the funnel”.

- The Teaspoon Fallacy: Certainty can be dangerous; humans often defend a “teaspoon” of information as if it were the entire ocean, leading them to dismiss valid ideas or safety concerns simply because they haven’t personally experienced them.

- Engagement is a Condition, Not a Command: Management cannot simply order workers to be engaged. True engagement emerges when managers create psychologically safe environments where even the “back row” feels comfortable speaking up and challenging the status quo.

- Neurodiversity as a Safety Asset: Individuals with neurodivergent traits often excel at early pattern recognition; leveraging these unique skill sets can help organizations spot risks that more neurotypical workers might miss.

- Aligning Three Critical Questions: To solve problems effectively, teams must agree on: what the problem is, what the long-term mission is, and whether short-term measures actually align with that mission.

Questions & Answers

Q: What is “Flow State” and how does it relate to safety?

A: Flow state is a zone of optimal performance where an individual is stretched just enough out of their comfort zone to learn and produce high-quality work without reaching the level of anxiety or stress that inhibits learning.

Q: Why does Bill Martin criticize the industry’s obsession with data?

A: Bill argues that data often reflects outcomes from years prior, and reacting solely to those results ignores the millions of interactions and shifting conditions that have happened since, making it difficult to prove that current actions are truly responsible for change.

Q: According to the episode, what are the four stages of psychological safety?

A: Citing Timothy R. Clark, the stages are: first, feeling safe to be included; second, safe to learn; third, safe to contribute; and finally, safe to challenge the status quo.

#UtilitySafety #PsychologicalSafety #UpstreamThinking #HumanPerformance #IncidentPrevention

Subscribe to Incident Prevention Magazine – https://incident-prevention.com/subscribe-now/

Register for the iP Utility Safety Conference & Expo – https://utilitysafetyconference.com/

The High-Voltage Sleep Gap – Why Rest is the Ultimate PPE with Dr. Eric Rogers

In this episode of the Utility Safety Podcast, host Kate Wade dives deep into the science of sleep with Dr. Eric Rogers, a performance sleep coach who has trained elite military units like the US Navy SEALs. Designed specifically for the high-hazard utility industry, this conversation reframes sleep from a passive recovery state to “the most powerful performance enhancer on the planet”.

Dr. Rogers explores the “inconvenient truths” about how alcohol and caffeine sabotage sleep architecture, the hidden dangers of “micro sleeps” during long shifts, and the life-threatening impact of untreated sleep apnea in the workforce. Whether you are a lineman navigating storm restoration or a leader looking to reduce driving-related accidents, this episode provides tactical, non-medicated strategies to ensure your brain remains the ultimate piece of PPE.

Key Takeaways

- The Brain as Primary PPE: While physical gear is vital, the brain is the command center for every decision; sleep is the primary factor ensuring it functions correctly in high-risk environments.

- The Danger of Micro Sleeps: These involuntary, split-second “brain shutdowns” occur during severe sleep deprivation and are a leading cause of driving accidents after long shifts.

- Alcohol’s False Promise: While alcohol acts as a sedative to help you fall asleep faster, it “wreaks havoc” on sleep architecture, resulting in poor quality, non-restorative rest.

- Tactical Napping & Caffeine: Strategic, short “tactical naps” (even 5 minutes) and early-shift caffeine use are effective tools for managing fatigue during emergency storm restoration.

- Circadian Rhythm Vulnerability: Human bodies are hardwired to be alert during the day; the “trough” of alertness between 2:00 a.m. and 5:00 a.m. makes night shifts and early morning commutes particularly hazardous.

- Cultural Shift in Leadership: Organizations must move away from “praising sleep deprivation” and instead build rest periods and “buddy checks” into job planning to protect workers and productivity.

Questions & Answers

Podcast Episode Overview: The High-Voltage Sleep Gap

Host: Kate Wade, Editor of Incident Prevention Magazine Guest: Dr. Eric Rogers, Founder of Peak Sleep LLC and former sleep specialist for US Navy SEAL teams

In this episode of the Utility Safety Podcast, host Kate Wade sits down with Dr. Eric Rogers to discuss why consistent, high-quality sleep is the most powerful performance enhancer available to utility workers. Drawing on his experience with elite military units, Dr. Rogers explains how sleep deprivation directly impacts the “command center” of the body—the brain—affecting judgment, risk-taking, and physical safety. The conversation covers the “inconvenient truth” about alcohol’s impact on rest, the mechanics of dangerous “micro sleeps” during long shifts, and actionable strategies like tactical napping and box breathing to manage fatigue in high-hazard environments.

Key Takeaways

- The Brain as Primary PPE: Sleep is the number one way to ensure your brain—the command center for every action—is functioning correctly to prevent bad outcomes.

- Alcohol and Sleep Architecture: While alcohol is a sedative that helps you fall asleep faster, it dramatically damages sleep quality by wreaking havoc on your sleep architecture.

- The 24-Hour Impairment Rule: Being awake for 24 hours straight results in reaction times and cognitive abilities equivalent to a 0.10 blood alcohol level.

- Micro Sleep Dangers: These involuntary “brain shutdowns” last from a fraction of a second to several seconds and often happen without the person even realizing it, particularly during repetitive tasks like driving.

- Circadian Rhythm Vulnerability: Human bodies have a natural “trough” or low point in alertness between 2:00 a.m. and 5:00 a.m., making this the most dangerous time for shift work and commutes.

- Tactical Napping: For workers on long shifts, even a 5-to-15-minute “tactical nap” can significantly reduce fatigue and the risk of micro sleeps.

Q & A

Q: How does sleep deprivation compare to alcohol impairment on a job site?

A: When an individual has been awake for 24 hours or more, their cognitive functions, such as reaction time, are equivalent to someone with a 0.10 blood alcohol level. While most crews would never work alongside someone who is actively drunk, many frequently work 24-hour shifts with that same level of impairment.

Q: What is the most effective way to stabilize your internal clock (circadian rhythm)?

A: The single best strategy is to set a consistent wake-up time and stick to it seven days a week. Dr. Rogers notes that waking up at the same time every day is actually more important for your circadian rhythm than going to bed at the same time.

Q: Why is sleep apnea a specific concern for the utility industry workforce?

A: Sleep apnea is a breathing disorder more common in men and those who carry extra weight or significant muscle mass in the neck area. Because it causes the person to briefly wake up dozens of times per hour, it leads to non-restorative sleep and dangerous daytime sleepiness, such as falling asleep unintentionally during meetings or at red lights.

Q: What can leadership do to change the culture around sleep and safety?

A: Leaders should move away from praising sleep deprivation and instead encourage proper rest. This includes building rest periods into job planning, encouraging tactical naps during shifts longer than 16 hours, and using “buddy check” systems for night shifts to ensure no one is working compromised.

#UtilitySafety #SleepPerformance #LinemanLife #SafetyLeadership #FatigueManagement #IncidentPrevention

Subscribe to Incident Prevention Magazine – https://incident-prevention.com/subscribe-now/

Register for the iP Utility Safety Conference & Expo – https://utilitysafetyconference.com/

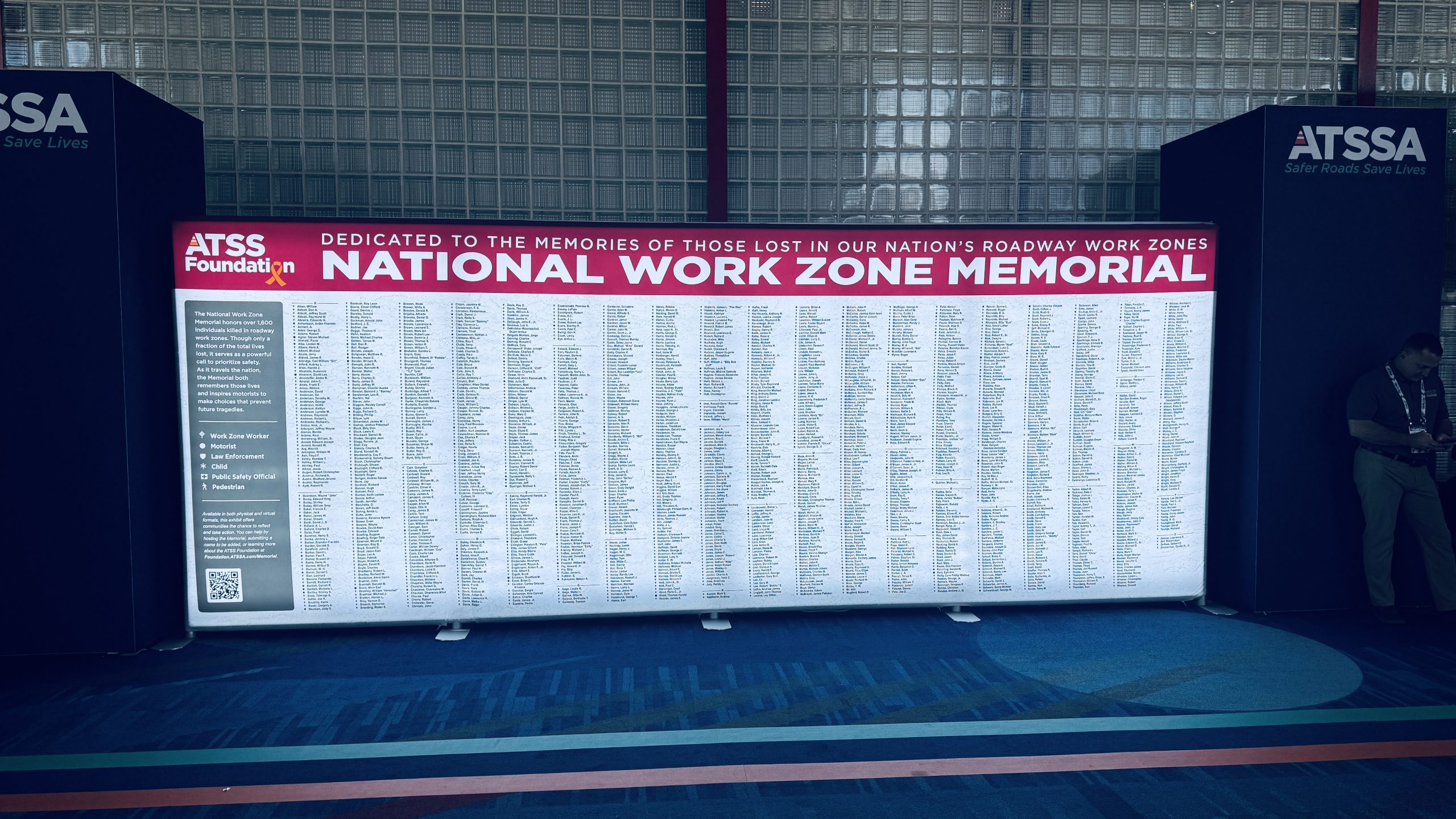

Advancing Safety: Incident Prevention Explores the Latest in Roadway Protection at American Traffic Safety Services Association (ATSSA) 2026!

For utility safety and operations professionals, the intersection of roadside work and live traffic remains one of the highest-risk environments. To stay at the forefront of hazard mitigation, Incident Prevention is on-site in Houston for the ATSSA Annual Convention & Traffic Expo, evaluating the next generation of life-saving technologies.

From AI-enabled work zone intrusion alarms to the newest MASH-compliant barriers, the innovations showcased at the ATSSA Expo are critical for any organization committed to “Target Zero” incidents.

Our team is specifically looking at:

- Connected Work Zones: Real-time digital alerting systems that bridge the gap between utility crews and motorists.

- Advanced PPE & Visibility: High-performance gear designed to ensure workers are seen in all weather and lighting conditions.

- Fleet Safety Innovations: New vehicle lighting and attenuator technologies that protect the mobile work zone.

Integrating these solutions into your Safety Management System (SMS) isn’t just about compliance; it’s about evolving your safety culture from a priority to a fundamental value. For a complete look at the exhibitors and the New Products Rollout, visit the official ATSSA Expo website.

-

IMG_7569

-

IMG_7570

-

IMG_7591

-

IMG_7585

-

IMG_7584

-

IMG_7582

-

IMG_7583

-

IMG_7577

-

IMG_7574

-

IMG_7573

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compliance systems and paperwork were in place. Yet we still failed our brothers and sisters.

That reality should eat at all of us because our industry could have done better then – and we should be doing better now. We must face the truth that not all safety methods work as intended. Without adjusting our approach, elimination of serious injuries and fatalities (SIFs) is nearly impossible.

The Illusion of Safety

One specific thing that keeps me up at night is the illusion of safety. Many of us are drowning in paperwork, but it is not meaningfully moving the needle in terms of SIF prevention.

Think about it. Nearly every incident we investigate circles back to either a lack of clarity or a lack of communication. Both are preventable forms of confusion. In allowing uncertainty to linger, we accept far greater risk than the cost of slowing down or stopping work to make things right.

Compliance is a science. It’s measurable, rigid, written in black and white. Regulatory and organizational rules tell us what’s permitted and what isn’t, what will pass an audit and what won’t. Safety, on the other hand, is an art. It’s dynamic, fluid, constantly changing. Because each jobsite is different, frontline workers must assess changing site conditions to identify hazards, applying what they’ve learned from their safety and compliance training to mitigate harm. This skill requires a combination of creativity, discipline and situational awareness in real time.

Unfortunately, the industry often considers compliance and safety as one and the same – and that’s a problem.

Job hazard analyses and pre-job briefings should never be treated solely as company-mandated compliance measures. Time spent on these activities should be dedicated to ensuring frontline employees truly understand the work and hazards ahead. Job forms signed without worker understanding are much like shields crafted from cheap paper: easily torn and ignored, potentially exposing users to fatal hazards.

The Courtroom vs. the Pole

Here’s another hard truth: While compliance measures often protect employers in courtrooms, that’s not necessarily the case for lineworkers.

Completed job forms help employers demonstrate to judges and juries that they fulfilled their legal obligations. But as any lineworker suspended 45 feet in the air will tell you, a signed job form will never support their weight as they work or prevent them or their coworker from making a potentially fatal error.

Sadly, some organizations have weaponized compliance paperwork, using it as grounds for discipline or termination. Yet it is critical to note here that compliance is not our enemy. This is about perspective. By viewing compliance as a safety tool rather than our end goal, we can focus on what we should be aiming at: sending workers home in the same condition they arrived in (or better).

Keep in mind that workers who believe safety rules and paperwork exist only to protect their employer will almost always sign their forms, nod during meetings and walk away unchanged – and likely unwilling to change.

Leadership Sets the Tone

This is an industry problem. Leadership sets the tone. Executives who speak about safety purely as a compliance metric send a message to crews, loud and clear, that employer liability concerns matter more than employee lives. When production is pushed at all costs, workers are taught that safety rules aren’t rules; they’re suggestions.

Good, strong leadership looks different. These executives invest in clarity and measure safety by how many workers return home uninjured, not the number of forms completed.

The fix to our industry’s safety culture is not complicated, but it requires courageous leaders who are willing to (1) prioritize employee understanding over signed job forms; (2) treat compliance paperwork as a living tool; (3) measure safety by outcomes, not optics; and (4) create organizational cultures in which workers believe the system exists to protect them.

Let’s stop pretending that more rules will save us. What we need is greater clarity, accountability and humanity in our approach. Safety is about people, not paperwork – but until we consistently treat it that way, we will keep paying the price.

About the Author: Stephen Shutt, CUSP, serves as an instructor and the director of powerline programs for Heavy Equipment Colleges of America. Reach him at stephen.shutt@hecofa.com.

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a priority—it naturally drives improvements in quality, productivity, and overall operational excellence. By utilizing Human and Organizational Performance (HOP) principles, the article highlights how a “safety-first” culture motivates employees to follow standards even when unobserved, ultimately reducing rework and fostering a more efficient workforce.

Read the article by Doug Hill, CUSP – Built In, Not Bolted On: Using Safety to Drive Operational Excellence

Key Takeaways

- Safety as a Value, Not a Priority: Priorities can shift depending on the day’s demands, but values remain constant. When safety is a value, employees adhere to standards because they see the inherent worth in them.

- The Interconnectivity of Success: Safety, quality, and productivity are not silos. A safe process is often a high-quality process that leads to productive outcomes.

- Human and Organizational Performance (HOP): Systems should be designed so that processes are easy to follow and make sense to the people actually doing the work.

- The Power of “Why”: Employees are more likely to follow protocols (like wearing PPE) when they understand the personal stakes (family, health, well-being) rather than just trying to avoid a reprimand.

- Learning from Success: Organizations should focus on learning from what goes right just as much as they learn from failures to identify opportunities for continuous improvement.

3 Questions and Answers

Q1: What is the main difference between safety being a “priority” versus a “value”? A1: A priority is something that can change based on circumstances or pressure (like a deadline), whereas a value is a core belief that remains constant regardless of the situation. When safety is a value, it is integrated into every action naturally.

Q2: How does the article suggest safety impacts productivity and quality? A2: The author uses the analogy of building a child’s bicycle: because you care about the safety of the rider, you follow instructions more carefully (Quality), which ensures the bike works correctly the first time and doesn’t require repairs (Productivity/Efficiency).

Q3: Why is “peer-to-peer support” mentioned as a critical factor in safety culture? A3: Because supervisors cannot be everywhere at once. A strong safety culture relies on workers looking out for one another and holding each other accountable to standards even when leadership is not present.

#UtilitySafety #OperationalExcellence #OccupationalSafety #HOP #WorkplaceCulture #IncidentPrevention

Subscribe to Incident Prevention Magazine – https://incident-prevention.com/subscribe-now/

Register for the iP Utility Safety Conference & Expo – https://utilitysafetyconference.com/

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

— Webinar Sponsored By —

“Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages”

** THIS WEBINAR WILL BE RECORDED **

Be sure to register. If you are unable to attend on the day of this event, you will still receive a link to the webinar recording afterwards so that you can access and view it at your convenience.

Join the Conversation With Industry Experts On March 12th at 1:00 p.m. ET

Hot spots on energized switches are often treated as isolated temperature issues, but in reality, they can be early warning signs of deeper mechanical, environmental, and lubrication-related problems. Left unaddressed, these issues can lead to unreliable switching, increased operating force, longer work windows, and higher risk in the field.

In this webinar, we’ll walk through what hot spots actually signal, the most common causes utilities see in the field, and how to evaluate when an issue can be addressed safely as part of an energized mitigation workflow versus when it truly requires an outage. Attendees will leave with a practical, field-tested framework they can apply immediately to improve reliability, reduce repeat issues, and make more informed maintenance decisions.

Learning Objectives:

- What hot spots really indicate beyond temperature—and why they shouldn’t be ignored

- The most common causes of hot spots on energized switches, including mechanical resistance, contamination, corrosion, and lubrication breakdown

- Early warning signs crews can recognize in the field before issues escalate

- How to evaluate the decision point between energized mitigation and scheduling an outage

- A practical Identify → Verify → Stabilize → Prevent framework utilities can use to manage hot spot issues

- Maintenance best practices that reduce repeat problems, including lubrication standardization and simple record-keeping

- How utilities can improve long-term switch reliability without increasing safety exposure or operational disruption

-

Attendees will gain a clearer understanding of how to interpret hot spots on energized switches and how to respond with practical, repeatable maintenance approaches that reduce risk, downtime, and unnecessary outages.

This is a must-attend event for operations managers, utility leaders, and anyone involved in disaster response planning. We encourage you to forward this webinar to the relevant executive and training stakeholders on your team.

Time will be dedicated at the end of the discussion to answer live audience questions.

Attendance worth 1 contact hour for certification/CUSP maintenance.

MEET YOUR SPEAKERS

Dale Mendoza

Sr. Technical Advisor FirstPower Group

Worked for So Calif Edison from 3/77 to 12/22, Retired. Most of the career was spent in substation maintenance with an emphasis on disconnects, DC systems, vegetation management, AR PPE and FERC/NERC compliance.

Chris Hill

Sales Manager FirstPower Group

Partners with utility teams to address switch and breaker maintenance challenges using practical, field-tested approaches.

FirstPower Group LLC (FPG) is a specialized industrial manufacturer and service provider dedicated to the maintenance and repair of high-voltage circuit breakers and compressors for the electric power industry. Founded in 2007, the company carries forward a legacy dating back to 1979, having roots in J.W. Harley Inc. and a subsequent period as part of GE Power Generation Services.

FPG distinguishes itself by applying decades of engineering expertise to modernize aging equipment, offering affordable solutions that improve productivity while reducing environmental impact. The company’s operations are guided by the principles of Kaizen and Lean manufacturing, focusing on the systematic elimination of waste and continuous operational improvement. Safety and reliability are paramount, with a workforce fully trained in OSHA standards to ensure the dependable delivery of electric services. Ultimately, FPG aims to be a global leader in equipment remanufacturing, driven by a customer-centric culture and a commitment to achievement.

The views, information, or opinions expressed during this webinar are solely those of the individuals involved and do not necessarily represent those of Utility Business Media and its employees. It is strongly recommended you discuss any actions or policy changes with your company management prior to implementation.

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat stress and injury.

The vest is constructed using the same proven technology as the FDA-approved CarbonCool system, which offers ultra-compact, rapidly deployable cooling performance that exceeds full ice-bath immersion with no need for ice, water or electricity. CarbonCool is an entirely dry cooling technology that is compatible with other medical interventions, including AEDs and diagnostic imaging.

To meet the demands of high-risk industrial environments, EMCOOLS recently introduced a flame-resistant ArcticCore Vest that complies with NFPA 2112, enabling safe deployment in settings where fire hazards exist.

The EMCOOLS ArcticCore Vest is also available with an optional hydration bladder, which can be frozen to extend the cooling duration while providing on-the-go hydration.

Email Global Healthcare SG (info@globalhealthcare.sg) or EMCOOLS (info@emcools.com) for clinical and peer-reviewed studies, OSHA guidance and demos. www.globalhealthcare.sg, https://emcools.com

Underground Conduit Installation Tool

Prevent soft-tissue injuries, minimize struck-by incidents, and reduce sprains and strains with the KNOCK’ER-IN pipe and conduit installation tool from Innisfree. Offering an alternative to the traditional 2-x-4 method of joining UG conduit, this tool helps to increase worker safety, productivity and comfort, 10 feet at a time. The molded polyurethane block coupled with a fiberglass handle and rubber handgrip provides a cushion for every blow, while the positioning shoe offers stabilization through the strike. Additionally, the KNOCK’ER-IN features a concave arch bottom – because sometimes you need to knock’er-off. www.innisfreetools.com

SRLs with Digital Safety Protection

Twiceme Technology, a company building the digital safety standard for jobsites and adventures, has expanded its partnership with height safety leader Guardian. Building on Twiceme’s existing integration in Guardian’s B7-Comfort Harness, it will now be integrated into 10 Guardian anchor-mounted self-retracting lifelines (SRLs), marking a first for the fall protection industry. The Twiceme-enabled SRLs from Guardian are expected to be available this spring.

These SRLs range from 16 to 65 feet, providing extended working distance while efficiently stopping the user from hitting the ground or next level in the event of a fall. With Twiceme’s integration into Guardian’s SRLs, organizations can use its safety management portal to access equipment health inspection and work document features, tracking on-site certification and ensuring PPE is safe and in good condition. The Medical ID features assist first responders in rescue missions. https://twiceme.com, https://guardianfall.com

Ground Protection and Access Mats

DICA is expanding its product portfolio with the introduction of its own line of ground protection and site access mats. The new Ranger HD, Defender and Titan mats provide contractors with high-performance, cost-effective access options for a variety of jobsites. DICA will debut the company’s light-, medium- and heavy-duty mats in March at CONEXPO-CON/AGG 2026 in Las Vegas.

Ranger HD is a 4-foot-by-8-foot, half-inch-thick mat designed for light-duty temporary access where hand deployment and surface protection are primary needs. Defender is a 3-foot-by-6-foot, 1-inch-thick medium-duty option with overlapping flanges that lock together. It is suited to a wider range of ground conditions, providing a more rigid surface for heavier equipment, such as concrete pump trucks, large material-handling equipment, boom trucks and rough terrain cranes. Titan access mats provide heavy-duty ground protection. The 2-inch-thick mats covering 71 square feet are designed for higher load requirements (e.g., heavy mobile cranes, crawler cranes). https://dicausa.com

Self-Rescue System

The Buckingham 401SRK Self-Rescue System is an emergency descent device designed to allow workers to safely perform self-rescue from an elevated position when no third party is present. The system utilizes an all-aluminum descent control device (DCD) featuring an anti-panic brake that ensures a safe, controlled descent from an elevated surface. The DCD incorporates a unique cam feature that provides smooth modulation, allowing the user to easily control descent speed by pulling the lever to find the optimal position. If the user pulls the lever too far, the DCD will stop the descent. Compact at only 7.5 mm, the Technora descent line is designed to withstand heat during long descents. The system includes two retro rappelling straps for use with any style full-body harness that does not have a rated attachment for rescue. This device is securely packed in a weather-resistant bag that can withstand an electric arc flash. The 401SRK system is available for one- or two-man buckets; the two-man bucket system includes two pairs of retro rappelling straps and two DCDs. https://buckinghammfg.com/products/self-rescue-system-401srk/

The Human Tuning Fork: Harnessing Frequency and Vibration for Utility Safety with Bill Martin, CUSP

In this episode of the Utility Safety Podcast, host Nick chats with Bill Martin, CUSP about a concept that goes far beyond the standard safety manual: the physics of human energy. Inspired by Nikola Tesla’s quote on energy, frequency, and vibration, Bill explains why workers are like “human tuning forks” and how one person’s attitude can physically resonate through an entire crew. The conversation dives deep into the biology of leadership, contrasting the stress of “command and control” with the high performance of synchronized teams. Bill also challenges the industry’s reliance on caffeine and energy drinks, arguing that true high performance starts with regulating your own physiology and inputs. Tune in to learn how to move from a state of basic compliance to a state of high-frequency synchronization.

Key Takeaways

- The Tuning Fork Analogy: Humans are like tuning forks; energy transfers between people without physical contact, meaning a single person’s mood or “vibration” can affect the safety and performance of the entire team.

- Synchronization Over Compliance: While “command and control” works in predictable environments, high-risk utility work requires synchronization—like pushing a swing in rhythm—to maintain forward momentum and safety.

- The Chemistry of Leadership: A leader’s approach triggers biological responses; criticism releases cortisol (stress/defense), while praise releases oxytocin (connection/higher cognition), changing the frequency at which the team operates.

- Impact of Substances: Reliance on energy drinks, caffeine, and alcohol dehydrates the brain and lowers cognitive frequency, effectively making workers “stupid” and slower to react in critical situations.

- The 5-Second Rule: To avoid reacting negatively to a “toxic” team member, use the 5-second rule (count down 5-4-3-2-1) to bypass your biological defense mechanism and choose a constructive response.

- The Power of Sync (Millennium Bridge): Just as the rhythmic walking of pedestrians caused London’s Millennium Bridge to wobble violently, a team that is perfectly synchronized can generate immense power and capability.

Questions & Answers

Q1: How does Bill Martin explain the concept of “making your own luck” regarding safety and life?

A: Bill explains that prediction is simply how our brains work to make things happen, rather than a lottery ticket. He argues that we are in 100% control of our next decision regardless of the hand we are dealt, meaning we decide if our “luck” is good or bad based on our mindset and actions.

Q2: Why does Bill suggest that energy drinks are detrimental to line workers?

A: Bill notes that energy drinks alter physiology by spiking heart rates, which the body struggles to distinguish from fear or running from a threat. He states that caffeine dehydrates the brain (which is 70% water), slowing down brain conduction and thinking speed, which is dangerous in high-stakes work.

Q3: What is the “marshmallow” effect in a team setting?

A: Using the analogy of Newton’s cradle (pendulum balls), Bill describes a person who is out of sync or vibrating at a low frequency as a “marshmallow”. If placed in the middle of the team, this person absorbs the energy rather than transferring it, stopping the team’s momentum.

Q4: How can a worker change the “frequency” of a negative interaction immediately?

A: Instead of reacting defensively to a bully or an angry coworker, Bill suggests smiling or staying silent for five seconds to disrupt their predicted response. By refusing to let the other person decide your energy, and instead responding with curiosity or kindness, you change the dynamic of the interaction.

#UtilitySafety #Leadership #TeamSync #HumanPerformance #Mindset #LineLife

Closing the Hazard Awareness Delay – Real-Time Grid Visibility with Active Grid Response

In this episode of Incident Prevention’s Utility Safety Podcast, host Kate Wade sits down with Tim Bedford, a 36-year veteran of PG&E and current Principal Customer Success Manager at Gridware. Together, they explore a critical new category of grid intelligence: Active Grid Response.

Tim explains the concept of “Hazard Awareness Delay”—the dangerous gap in time between a grid event occurring and the utility becoming aware of it . By utilizing Gridware’s Gridscope, a mechanical sensing device installed on poles, utilities can now detect hazards like broken poles, vegetation impact, and conductor vibration in real-time .

Listen in to learn:

- How real-time grid visibility eliminates unnecessary exposure for linemen, drastically improving utility safety.

- The role of mechanical sensing in preventing wildfires by identifying risks before they ignite .

- How Gridware’s technology creates a “zero delay line break” response, potentially de-energizing falling lines before they hit the ground .

- Strategies for funding safety technology through reliability and fleet maintenance budgets .

Whether you are in operations, safety management, or fleet logistics, this episode offers actionable insights into modernizing grid protection.

Guest Contact: Tim Bedford | tim.bedford@gridware.io Learn More: www.gridware.io

Key Takeaways

- Defining Hazard Awareness Delay: This is the critical time lapse between an event occurring on the electrical system and the utility’s awareness of it; reducing this delay prevents outages and catastrophic events like wildfires.

- Mechanical Sensing Technology: Gridware’s “Gridscope” acts like a pickup on a guitar string, detecting vibration, sound, and pole angle changes to pinpoint exact fault locations without needing to patrol the entire line.

- Enhancing Lineman Safety: By providing the exact location of a fault, utilities reduce the need for linemen to patrol hazardous terrain in the dark, significantly lowering safety risks and exposure.

- Rapid Installation: The devices are approximately the size of a shoebox, weigh 3.5 lbs, and can be installed in under five minutes; a single crew can install upwards of 50 devices per day.

- Future “Zero Delay” Capabilities: Gridware is currently piloting technology that can detect a line break and trigger a recloser to de-energize the circuit before the wire even hits the ground.

Q&A: Utility Safety & Grid Visibility

Q: What is the “Active Grid Response” solution provided by Gridware?

A: Active Grid Response is a new category of grid intelligence that provides real-time visibility into the physical, electrical, and environmental conditions of the grid. It uses sensors to monitor vibrations and pole angles, allowing utilities to identify specific hazards—like a tree striking a line or a car hitting a pole—before they escalate into major outages or wildfires.

Q: How does this technology directly improve utility safety for the workforce?

A: It drastically reduces the “hunt and seek” method of finding faults. Instead of a troubleman patrolling miles of line in hazardous conditions (darkness, rough terrain, severe weather), the system provides a pinpoint location . This minimizes the time employees spend in dangerous environments and reduces fleet vehicle exposure .

Q: Is this technology cost-prohibitive for smaller utilities or tight budgets?

A: Tim Bedford suggests that funding often comes from shifting budgets based on the use case. For example, the technology offsets costs in fleet fuel, engine hours, and patrol time. Additionally, it can replace less effective legacy devices like standard fault indicators, and deployments can be scaled to focus only on high-risk protection zones rather than the entire system immediately.

Subscribe to Incident Prevention Magazine – https://incident-prevention.com/subscribe-now/

Register for the iP Utility Safety Conference & Expo – https://utilitysafetyconference.com/

#UtilitySafety #GridModernization #LinemanSafety #WildfirePrevention #SmartGrid #ActiveGridResponse

Managing Overload: An Essential Safety Conversation

When I consider the advancements in the construction industry over the past 20 years, the emphasis on safety is one that immediately stands out. Today, we continue to strive to elevate our safety awareness, knowledge, training and program development – but that is only one side of the coin. On the other side, our workforce is experiencing concerning rates of turnover, burnout, mental exhaustion and suicide.

But how can this be our reality if our jobsites have become safer in recent decades?

The answer is directly tied to the way we manage overload. To help explain this, let’s look at three commonly understood areas – exercise science, electrical energy and mental health – that require proper overload management to yield the greatest benefits.

1. Exercise Science: Progressive Overload and Rest

The roots of exercise science are often traced to the story of Milo of Croton, an ancient Greek athlete. As a young boy, Milo carried a small calf on his shoulders each day. The two grew together, and after years of consistent effort, Milo was carrying a full-grown bull. His strength had increased in direct proportion to the bull’s growth.

Modern exercise science recognizes progressive overload as fundamental, with workouts intentionally designed to incrementally increase the stress placed on targeted muscles over time. Muscle will not experience hypertrophy or gain functional strength unless it has been pushed beyond its current limitations.

However, intentional stress must also have a limit. That is because muscle growth occurs in a state of rest and recovery, not in the moment of overload. If the muscle never rests, growth will be minimal or even regressive. Thus, overload must be managed properly, with an emphasis on rest, to reduce injury and achieve muscle growth.

2. Electrical Energy: Fixed Limits and Preventive Maintenance

Electrical energy is a largely unobservable force that is generated, transmitted and distributed via observable components. Each component of an electrical circuit must be capable of safely withstanding the demands placed upon it. When calculating system load, keep the components’ known limitations in mind to avoid creating an overload condition.

Electrical components, unlike the human body, do not benefit from progressive overload. They have a fixed failure point, where load demand exceeds rated capacity. Both electrical and mechanical components depend on preventive maintenance for safe, reliable operation.

Preventive maintenance programs have become standard practice in the utility sector, helping to ensure functionality and longevity. Inspections and repairs must only be done after electrical components have been verified as de-energized. Once again, overload is properly managed through deliberate rest.

3. Mental Health: Neuroplasticity Needs Recovery

The human brain is remarkable, in part because of its neuroplasticity, or the capacity to adapt in response to stimuli. The new neural connections created when the brain experiences stress are neuroplasticity at work. Moderate stress can drive positive adaptation and growth; unrelenting levels have the opposite effect.

As with exercise science and electrical energy, rest is essential here. The brain’s stress load must be relieved to allow neuroplasticity to produce positive, sustainable change – instead of damage. In other words, rest is how mitigation is achieved.

Where Do We Go From Here?

In 2026, we understand more than ever about exercise science, electrical energy and mental health. We know we cannot train our muscles all day if we want them to grow, and we understand that electrical system reliability depends on scheduled, de-energized maintenance. We have also begun to admit that the human brain is no different. Under constant load, and without real recovery, it will fail.

We are making huge strides in physical safety, too. Guards, personal protective equipment, procedures and programs are better than they have ever been. But when it comes to the human side of safety, we are merely at the starting line. Chronic overload experienced by our foremen, supervisors and managers is quietly eroding the very performance we are asking them to deliver. This must become a safety conversation.

Progressive overload is a powerful tool for building skills, knowledge and capability – but only when it is paired with deliberate rest and preventive maintenance. On the job, that means we must watch for early signs of mental fatigue, normalize the use of support resources, and give our key people time and space to recover.

We will always need power for our electrical systems and productivity for our projects, but we cannot forget the simplest truth of all: In the electric utility industry, safety isn’t just about the energy we lock out. It’s also about recognizing when our employees have reached maximum overload and then effectively responding to prevent them from experiencing burnout or worse.

About the Author: Rob Duplain is a superintendent for Virginia-based Miller Electric Co. A former police officer and graduate of Taylor University who earned a bachelor’s degree in sociology, he joined the International Brotherhood of Electrical Workers in 2010.

Layer by Layer: Leveraging FR Clothing Systems for Hazard Protection and Comfort

Layering flame-resistant (FR) clothing has long been a best practice among industrial athletes. In addition to providing critical hazard protection, this tried-and-true strategy enhances user comfort by enabling industrial athletes to add or remove clothing layers as their activity level or the weather changes.

Base, middle and outer FR layers are equally important. Each serves its own purpose, so it is wise for lineworkers to own all three types.

Base Layer: Moisture Management

This next-to-skin garment layer wicks moisture away from the body, a function that becomes especially important in frigid conditions, lowering the user’s risk of chills and hypothermia by keeping the skin dry and warm. Base layers are offered in various fabric weights, with a general rule of thumb that the heavier the fabric, the warmer it will keep you – so long as it wicks properly.

Keep in mind, however, that the primary purpose of an FR base layer isn’t to increase your warmth. Beyond offering hazard protection, this layer is intended to pull moisture away from the skin. So, when shopping for an optimal base layer, choose a quick-drying garment that offers permanent moisture-wicking performance. Permanent moisture management is achieved through a blend of hydrophobic/water-hating and hydrophilic/water-loving fibers. Manufacturers that make claims about their fabrics’ moisture-management benefits but don’t use this type of fiber blend typically rely on topical finishes that will wash out over time, diminishing garment performance.

FR fabric blends with proven moisture-management properties are available from numerous industry vendors. As you spec and select garments, ask for this and other relevant data to help guide your purchasing decisions.

Middle Layer: Insulation

The middle layer of an FR clothing system also moves moisture, similar to a base layer, but its primary role is helping users retain their body heat. Essentially, the more efficiently this layer traps heat, the warmer you will be. Fabric weight can be adjusted by users to match changing conditions; this is where the art of layering truly begins.

Here is just one example: Your shift starts early in the morning, when temperatures will be their lowest for the day. You opt to wear a base layer, a heavier midweight layer and a protective outer shell, all appropriately rated for the hazard exposure. As your body warms and the ambient temperature rises, you decide to swap your midweight layer for a lighter option that still provides adequate flame protection.

Ideally, industrial athletes will own middle layers in various fabric weights, including a heavier FR fabric for colder weather, giving themselves the flexibility to add or shed layers for comfort. Remember to select middle layers that provide permanent moisture-wicking performance. As with base layers, this feature helps to ensure fabric stays dry even as temperatures and physical activity levels rise.

Outer Layer: Wind, Rain and Snow Protection

Your outer FR layer should be breathable and wick moisture, but more importantly, it must protect you from the elements. Any wind or water given the opportunity to penetrate inner garment layers can quickly chill you, making this layer especially critical during storms.

One common consumer mistake is choosing an outer FR layer that’s too heavy and/or doesn’t breathe well, trapping moisture inside and providing subpar protection from wind, rain and snow. Outerwear should allow moisture to escape while being lightweight enough to allow the user’s freedom of movement. An FR clothing system that includes an outer layer with permanent moisture-wicking performance can move moisture from one layer to the next until it evaporates into the atmosphere.

Conclusion

Moisture-wicking technology was initially developed to enhance athletes’ performance in extreme outdoor environments, keeping them cooler and drier in hot conditions and warmer and drier in cold ones. Today, industrial athletes – like lineworkers – can take advantage of moisture-wicking, high-performance FR garments and well-designed layering systems to help keep them safe and comfortable in hazardous outdoor work environments.

About the Author: Brad Sipe is the director of business development for Lakeland Fire + Safety’s HPFR Division and a 25-year veteran of the apparel industry. Reach him at bssipe@lakeland.com.

*****

Selection Tips for Base, Middle and Outer Layers

Base

- Choose a base layer with permanent moisture management, which will help to ensure full lifetime performance of the garment.

- An optimal blend of hydrophobic and hydrophilic fibers is key. This combination pulls and pushes moisture through the FR fabric so that it spreads and dries more effectively. Ask vendors for garment data – it’s available – and be sure to check labels to confirm fiber blends.

Middle

- For flexibility, select FR middle layers in different fabric weights. These garments can be swapped out as temperatures and activity levels change.

- Ensure middle layers provide permanent moisture-wicking performance.

Outer

- Choose outerwear that will adequately protect you from wind, rain and snow.

- Make sure the FR garment is lightweight, breathable and incorporates permanent moisture management.

Cable Identification and Cutting Safety for Medium-Voltage Splicers

A medium-voltage underground splicer’s ability to safely and correctly identify, test and cut cable is more than part of their job; it is a survival skill. These splicers must be trained to make their first cut remotely – every time – whether performing routine maintenance or responding to an emergency, even when the cable has been tested and grounded. This approach ensures the worker is safely out of harm’s way if residual or unexpected energy remains in the system.

Procedural Development and Training

Proper cable identification supports operational efficiency, helping to minimize outages, reduce the risk of damaging cable and equipment, and expedite the restoration process after service disruptions.

Because misidentifying and/or improperly cutting a live cable can result in severe injury or death, utility organizations ideally develop and train employees on stringent cable identification procedures. Splicers must learn to use a combination of testing, grounding and electronic tracing to confirm cable identity before proceeding, regardless of the environment or circumstances.

Employers are legally required to comply with OSHA standards, which outline what they must accomplish to protect employees. Utility-specific guidelines also provide direction about how work is to be safely performed.

Layers of Defense

Cable splicing mirrors high-risk switching operations, which means that personal protective equipment is critical to worker safety. Standard PPE for a medium-voltage splicer includes a hard hat, safety glasses with side shields, steel-toe boots and flame-resistant clothing rated for the hazard exposure. Depending on the voltage and situation, a splicer may also need to wear rubber gloves, sleeves and arc-rated garments in exposed energized environments. Insulating hot sticks and grounding equipment are equally essential. Note that all PPE and tools must bear valid inspection stickers to confirm they are safe for use. The hazards of underground electrical work leave no room for shortcuts.

Lockout/tagout procedures offer another layer of defense. Once a cable has been identified, the splicer must work with dispatch to locate the nearest sectionalizing switches and isolate the line. Testing verifies the line has been properly switched out, and grounding removes any remaining induced voltage. Only then should a tag be placed on the equipment, clearly indicating that the cable must not be re-energized until the tag has been removed under the authority of dispatch and the worker who affixed it.

Modern electronic cable identification methods may not be available or reliable in some cases. Corroded grounds, damaged markers and other factors could force splicers to use traditional verification techniques, such as checking duct position numbers, verifying tags and footage markers, using blowers to feel air movement through ducts, and performing tug tests. Under no circumstances, however, should a snake be run through a duct unless the cable has first been proven de-energized.

Helpful Tools

Various advanced tools are available to help workers improve identification accuracy. Impulse test kits help to locate and phase identify direct-buried or conduit cables up to 20 miles long, including submersible cable. Using a transmitter that sends electrical impulses combined with a clamp-on receiver that reads the signals, splicers can accurately identify both single-phase and three-phase systems. Calibration and careful use of these tools are essential to prevent false readings.

Even with reliable identification tools, the process does not end once a cable is located and phased. Remote cutting is the final safeguard. No matter how certain the splicer is that a cable is de-energized, they must perform the first cut at a distance. Cutting implements can be selected based on the working environment. Grounded hot-stick cutters allow for smaller cable cuts from outside confined spaces. Bluetooth-enabled cutters can be operated remotely while secured in position to prevent accidental swings. Hydraulic cutters, with hoses and cords extending up to 40 feet, allow workers to stand clear of the cable during an initial cut. Regardless of the method, the objective remains the same: Keep workers out of the line of fire until the cable is fully severed.

The tools referenced here can help save lives – but only if they are in good condition. Follow manufacturer guidelines, store tools clean and dry in protective cases, and keep them shielded from unnecessary vibration and other exposures that could upset their calibration. With its constant bumps and jolts, a splicing truck is no place for delicate instruments unless they are properly secured. Dedicated, climate-protected storage ensures these devices remain reliable when they are needed most.

The Bottom Line

When it comes to cable identification and cutting, one principle stands above the rest: Treat every cable as if it is energized until proven otherwise – and maintain a margin of safety even then. By creating layers of defense with PPE, lockout/tagout procedures, proven tools and remote cutting, splicers safeguard themselves, their coworkers and the communities they serve. Underground cable work is largely unforgiving, but it can be performed safely and efficiently when approached with caution, precision and respect.

About the Author: Mark Savage is the owner of DeadBreak, a service-disabled veteran-owned small business providing underground distribution and transmission training, consulting and field services. A U.S. Marine Corps veteran with over 25 years of experience in underground construction and emergency response, Savage is a credentialed journeyman cable splicer/lineman and qualified medium-voltage splicing trainer. Reach him at msavage@deadbreak.us.

Overcoming Safety’s Blind Spot

“If you’re not prepared to be wrong, you’ll never come up with anything original.” -Sir Ken Robinson

Innately curious and hardwired to seek order, humans often grasp onto the latest ideas and inventions that help us satisfy our need to understand the world around us. Don’t believe me? Consider geocentricism, or the now-obsolete belief that the Earth is the center of the universe.

In earlier millennia, we followed herds of animals as they migrated, all of us sleeping under the stars. Our ancestors knew the night sky better than many of us do today. As they watched their world revolve around them, they assumed that the universe must have been created in service to them – right up until the works of Copernicus, Galileo, Kepler and Newton confirmed heliocentrism (i.e., that the sun is the center of our solar system).

Naturally, our ancestors were slow to accept this new information because changing deep-seated beliefs is no easy feat. They experienced discomfort and outright fear, preferring the warm and fuzzy feeling derived from trusting that the universe was solely focused on their needs.

Much like our ancestors, humans today often feel certain that we know all there is to know. When we dip a teaspoon into the proverbial ocean of available knowledge and find no whales, it is easy to assume whales do not exist. There weren’t any in our saltwater sample, right?

I noted earlier that it is not uncommon for us to acquire a small amount of information and run with it. Sometimes we will even protect and defend that information when someone challenges us or proves us wrong. Why do we respond in that manner? Well, our beliefs feel like a cozy security blanket, and our discomfort is provoked when someone snatches that blanket away. Though modern human society has undoubtedly evolved, the reality is that we are not vastly different from our ancestors. One exception is that in 2026, there is no valid reason why we shouldn’t trade in our teaspoons for much larger buckets of knowledge.

Predictive Processing Errors

We should not be surprised that safety has evolved in much the same way, given that it is a product of human systems and behaviors. Still, recognizing that can be difficult without the proper perspective. Let’s start by acknowledging that so long as we are breathing, there exists an infinite number of circumstances, decisions and other possibilities that could impact us. These possibilities intersect – again, in infinite ways – sometimes combining to produce worksite incidents. Yet too many industry professionals believe that we can identify and prevent the limitless number of potential event scenarios, using incident analyses to determine and address root causes.

Incidents stem from predictive processing errors, which is just a fancy term for certain mistakes made by the human brain. Here is the critical part that readers must understand: We cannot and will not predict an incident that we have never previously experienced or imagined or do not believe could occur. Recall the teaspoon-and-whales fallacy referenced earlier.

Time constraints and other job pressures are not uncommon in our industry. When we feel as though we must make a snap decision, the brain looks for cues and patterns based on our previous experiences and education. It will not make any decisions based on information it does not possess. In other words, greater intelligence and safer jobsites are much more likely to emerge when we share information with each other, preferably in healthy group settings that support quality interactions.

But here’s the catch. First, the human brain wants to conserve as much of the body’s energy as possible. Second, many of us are painfully aware that some individuals and working environments require more of our energy than others do. With that said, we can try to avoid interacting with coworkers who deplete us, but we also must realize that nothing results from a conversation that never takes place. No one will learn anything new that could enhance safety for all.

Optimism Bias and Experiential Blindness

Optimism bias – or a person’s inclination to underestimate the likelihood that something could go wrong – is a predictive processing error often made when the brain is in a state of experiential blindness. Our ability to accurately predict future events is severely hampered if we have never experienced those scenarios or imagined they could happen. Discovering our mistakes can be troubling as well, often triggering an emotional response that blocks the brain’s frontal lobe – the part that controls our critical thinking and executive functions.

Keep the previous paragraph in mind as we work through this next part. Let’s say someone raises a concern during a job briefing that is almost immediately dismissed by the rest of the crew. A concern shot down that quickly will likely never elicit any feedback or suggested actions from the group. But what if we reframe the way we think about concerns, treating them as predictions of unwanted outcomes? The more concerns that we raise, the more possibilities we can imagine, which increases our likelihood of identifying mitigation strategies that protect employees, customers and the public.

Safety is a product of our interactions on the job. Humans have invented the social hierarchy that exists in many organizations, but here is the reality: Every single worker is a piece of our puzzle. Remove one of them and outcomes change. The same is true in non-utility environments. For instance, a patient’s care could be undermined if the sheets on their hospital bed are soiled or their meals haven’t been carefully prepared. The next time you decide to bake your favorite loaf of bread, omit a couple of ingredients and let us know if it looks and tastes the same way you remember.

Tracking Events That Don’t Happen

Stop me if you’ve heard this one before: “If we can’t measure it, we can’t manage it.” That may be true for many things, yet it is not wholly accurate for safety. Yes, we collect and analyze data after incidents have occurred. But in an organization that fosters high-level, quality interactions among workers – interactions that enable us to carefully and intentionally move forward together through uncertainty – how do we measure and manage those incidents that never happened because of our safety efforts? The simple answer: We don’t. Instead, we focus on learning what we can from every outcome – wanted, unwanted, expected and unexpected.

Upstream Signals

There is one last thing I want to mention here. Since we do not typically notice what we are not looking for, we can miss weak upstream signals that point toward unwanted and unexpected outcomes. That means we must make a concerted effort to improve our observational skills, with success greatly dependent on team dynamics. Is there synchrony among our team? If not, who or what is out of alignment?

Our next safety meeting could provide some clues. While there, observe who is sitting in the back of the room. Have those individuals mostly assumed the same body language and posture, such as crossing their arms? Isn’t that interesting when we consider the tidy sum many of us are willing to pay for good seats to an event we are eager to attend? In fact, I do not believe our workers who sit in the back row, arms crossed, are consciously or voluntarily making that choice. I believe their behavior is an indicator of an unsettling, undefined “something” occurring upstream in the organizational system.

Conclusion

Safety should be about playing to win – not merely playing not to lose. To continue the utility industry’s safety evolution, it is imperative that we foster work environments in which concerns are treated as predictions of unwanted outcomes and our interactions with one another are considered opportunities to expand our collective intelligence.

About the Author: William N. Martin, CUSP, NRP, RN, DIMM, is president and CEO of Think Tank Project LLC (www.thinkprojectllc.com) and SAFR LLC. A third-generation electric utility worker and medical professional with extensive experience in high-risk operations and emergency medicine, he served nearly 20 years in lineman, line supervisor and safety director roles. Additionally, Martin spent 23 years as a critical care flight paramedic and registered nurse with cardiology and orthopedic experience. He earned a Diploma in Mountain Medicine and was an instructor/trainer for the National Ski Patrol. Currently, Martin writes and speaks nationally about safety and human performance, with a special focus on unleashing human potential.

Mental Preparation for Safer Work

Author’s Note: The first part of this five-part series (see https://incident-prevention.com/blog/when-the-system-isnt-enough-how-to-create-personal-motivation-that-saves-lives/) explored the notion of accepting 100% accountability for our safety at work. This article addresses mental preparation to reduce risk of serious injuries and fatalities. Part three will cover spiritual health, with a focus on clarifying and leveraging our own deeply held beliefs.

*****

Combat had endless tests, and one of the worst sins was “chattering” on the radio, which was reserved for essential messages; loose talk showed the wrong stuff. A Navy pilot once yelled, “I’ve got a MiG at zero!” as the enemy locked on his tail. An irritated voice cut in: “Shut up and die like an aviator.”

–Paraphrased from Tom Wolfe’s “The Right Stuff”

Are U.S. Navy pilots really born this way?

Many lineworkers have their own phrase: “He is a good hand.” While understated, it is meant to describe the pinnacle of lineworker excellence. But what is the “right stuff” in our industry? Calm, cool and collected? Competent, stoic and thoughtful? The kind of person who can say, “Houston, we have a problem” without missing a beat? Do we expect a lineworker to perform a thorough job briefing or safety analysis during a heat wave in the same way astronaut Jim Lovell calculated trajectories for Apollo 13’s return inside an overheated space capsule?

Navy pilots aren’t born calm, and lineworkers aren’t born good hands. These are learned behaviors cultivated through training, character development and good habit formation. As such, this article will not provide readers with a single definition of the right stuff. Instead, it will explain the origins of our natural dispositions and how we can evolve into people others trust with their lives.

What You’re Born With vs. What You Build

Since we’re not born ready-made for hazardous work, it is helpful to understand the raw wiring we begin our lives with and the patterns we develop over time.

Temperament is your nervous system’s factory setting, the tendencies you exhibited as a toddler and probably still demonstrate today. Some of us are naturally quiet and steady while others jump right into the center of things. None of this is good or bad. It is simply your starting point.

Your personality, or learned response to life, is shaped as your temperament interacts with your environment. You can thank everyone you have ever known for influencing it. Personality is the ongoing negotiation between who you are on the inside and what the external world expects of you. Some struggle with this balance, but most manage it well enough.

Emotional reactions arise from the interplay of both. Like voltage seeking ground, every moment is matched against your temperament and personality. Experiences in line with your natural tendencies generate little emotional current, while those that conflict create spikes. If someone threatens your family, for example, you’ll almost certainly feel it at full wattage; less so if someone hands you a package of peanut M&M’s instead of the plain ones you prefer.

Strong spikes become trigger points that can create havoc. Thankfully, David Rock, Ph.D., devised the SCARF Model, a cheat sheet for understanding these emotional triggers. In simple terms, the typical adult will have an emotional response to a perceived threat against their sense of status, certainty, autonomy, relatedness or fairness. The bigger the threat, the bigger the reaction – works every time. Consider an apprentice who has just been insulted in front of the rest of the crew. Depending on their temperament, they may react loudly and immediately or quietly a few hours later. For some it will be an immediate fistfight; others will prefer nailing your favorite hard hat to a pole when you’re not around.

What Predicts Safe Behavior?

Once you know what sets you off, you can train yourself to manage those triggers and influence safety in the field. Psychologists have studied five core personality traits – measured by the Five Factor Model, which has been supported by numerous studies since 1992 – that predict safety-related behavior. Taking this assessment can help you understand your temperament, personality, emotional triggers and how likely you are to work safely in hazardous conditions. The five factors are:

- Conscientiousness: High assessment scores indicate deliberate, careful work. Low scores suggest carelessness.

- Neuroticism: High scores signify impulsive, reactive behavior, especially under stress. Low scores mean stability, calm and steady decision-making.

- Extroversion: High extroversion can either lead to distraction and horseplay or, with genuine competence, turn into strong, vocal advocacy for safety.

- Agreeableness: High scores mean you’re cooperative, willing to follow rules and a team player.

- Openness: Being open to untested approaches in hazardous situations can be risky, but being cautiously open to new safety tools and methods is a plus.

It is in your best interest to know your Five Factor scores, which highlight natural risks and areas that may need development. Although personality does not dictate your decisions, it does strongly influence your likeliest choices, and most of us are more predictable than we realize. Five Factor assessment results often confirm an individual’s suitability for line work, but even then, understanding these traits provides clearer insights into how we operate internally.

Personality Can Change With Practice

Now that we know which traits influence safe behavior, the question is, can we modify our own personal traits to enhance our safety in the field? Contrary to popular belief, the answer is yes – but there are three requirements: (1) willingness to change your behavior, (2) belief that you can change and (3) consistent practice until the new behavior becomes habit.

This may sound like psychobabble, but it is based on the same principle as boot camp, during which character development trains emotions. Boot camp attendees typically walk in with one disposition and walk out with another. Line apprenticeships work the same way. Often, there is a notion that we rise to the occasion, but the reality is that we sink to our level of training. True mastery is on us. It is – and can only be – a personal choice.

Elite athletes and special operations soldiers are prime examples. Their careers demand constant mastery, so they relentlessly concentrate on how they eat, move, sleep, communicate, focus, make decisions, plan their work and avoid complacency. Their apprenticeship never really ends.

In the utility world, effort often tapers once someone tops out, but we shouldn’t give up once we’ve “made it” because injuries and fatalities still happen. True mastery doesn’t stop at the peak; it’s up to each of us to keep learning and improving. Full accountability for our own safety means we shouldn’t ignore anything that could give us an edge.

Upgrading Your Mental Firmware

If your temperament is the factory setting of your nervous system, then mastery comes from upgrading the mental firmware that runs on top of it. The first step is understanding how you’re built (i.e., your natural temperament and the personality you’ve developed over time). The next step is intentionally improving how you operate.

This is when models like SCARF become useful. In addition to explaining why you react the way you do, they also help you predict what will set you off, enabling you to manage your pressure points before they manage you.

Note: Because this work is deeply personal, these upgrades should always be voluntary and confidential.

Here are the four steps I train clients to use when upgrading their mental firmware:

- Understand how thinking and emotion interact: Recognize what high-quality decisions look and feel like, especially under pressure.

- Strengthen habits: Build routines that make safe behavior automatic, not optional.

- Improve attention and focus: Stay mentally present and resist complacency.

- Visualize work processes before the day begins: Perform a mental pre-mortem – picture the job, identify hazards and make adjustments – before stepping onto the site.

All of these skills can be trained on, practiced and improved. In combination, they help to close the gap between who a person is naturally and the person the work requires them to be to keep themselves safe.

A Deliberate Endeavor

The right stuff isn’t magic or something bestowed upon you. It’s developed deliberately over time by people who want to be the best at what they do and go home whole. Everyone employed in a hazardous trade has the capacity to develop the right stuff, but it will only happen when workers learn who they are, understand their triggers and commit to mastery.

About the Author: Tom Cohenno, Ed.D., CSP, CUSP, NBC-HWC, is a recognized safety expert and principal of Applied Learning Science (https://appliedlearningscience.com). With deep academic and operational experience as a U.S. Navy veteran, substation chief and former utility executive, he blends real-world insight with evidence-based research to deliver practical, impactful safety solutions.

*****

To learn more about Dr. David Rock’s SCARF model, read “SCARF: A Brain-Based Model for Collaborating With and Influencing Others” (see https://schoolguide.casel.org/uploads/sites/2/2018/12/SCARF-NeuroleadershipArticle.pdf) and “Managing With the Brain in Mind” (see https://davidrock.net/wp-content/uploads/2016/06/ManagingWBrainInMind.pdf).

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazards they introduce. Understanding how battery systems are governed under OSHA 29 CFR 1910.1200, “Hazard Communication,” is essential to ensuring worker safety, regulatory compliance and operational reliability.

Energy Storage and the HCS

Electric utilities sit at the center of the energy transition. The shift toward renewable generation, distributed energy resources and grid modernization has made large-scale energy storage critical to system reliability. Lithium-ion batteries have revolutionized grid-scale storage with fast response times, high efficiency and the ability to smooth fluctuations in renewable output. Meanwhile, sealed lead-acid batteries remain vital in substation operations, providing emergency power for relays, switchgear and communication systems. As utilities expand energy storage, workers encounter a growing variety of battery chemistries and configurations, each with distinct hazards that must be identified, communicated and controlled.