Articles

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compliance systems and paperwork were in place. Yet we still failed our brothers and sisters.

That reality should eat at all of us because our industry could have done better then – and we should be doing better now. We must face the truth that not all safety methods work as intended. Without adjust…

Managing Overload: An Essential Safety Conversation

When I consider the advancements in the construction industry over the past 20 years, the emphasis on safety is one that immediately stands out. Today, we continue to strive to elevate our safety awareness, knowledge, training and program development – but that is only one side of the coin. On the other side, our workforce is experiencing concerning rates of turnover, burnout, mental exhaustion and suicide.

But how can this be our reality if our jobsites have become safer in recent decades?

The answer is directly tied to the way we manage overload. To help explain this, let’s look at th…

Layer by Layer: Leveraging FR Clothing Systems for Hazard Protection and Comfort

Layering flame-resistant (FR) clothing has long been a best practice among industrial athletes. In addition to providing critical hazard protection, this tried-and-true strategy enhances user comfort by enabling industrial athletes to add or remove clothing layers as their activity level or the weather changes.

Base, middle and outer FR layers are equally important. Each serves its own purpose, so it is wise for lineworkers to own all three types.

Base Layer: Moisture Management

This next-to-skin garment layer wicks moisture away from the body, a function that becomes especially import…

Cable Identification and Cutting Safety for Medium-Voltage Splicers

A medium-voltage underground splicer’s ability to safely and correctly identify, test and cut cable is more than part of their job; it is a survival skill. These splicers must be trained to make their first cut remotely – every time – whether performing routine maintenance or responding to an emergency, even when the cable has been tested and grounded. This approach ensures the worker is safely out of harm’s way if residual or unexpected energy remains in the system.

Procedural Development and Training

Proper cable identification supports operational efficiency, helping to minimize outage…

Overcoming Safety’s Blind Spot

“If you’re not prepared to be wrong, you’ll never come up with anything original.” -Sir Ken Robinson

Innately curious and hardwired to seek order, humans often grasp onto the latest ideas and inventions that help us satisfy our need to understand the world around us. Don’t believe me? Consider geocentricism, or the now-obsolete belief that the Earth is the center of the universe.

In earlier millennia, we followed herds of animals as they migrated, all of us sleeping under the stars. Our ancestors knew the night sky better than many of us do today. As they watched their world revolve aro…

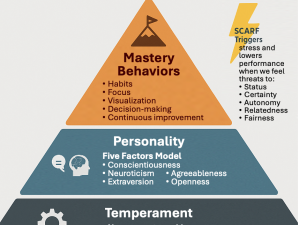

Mental Preparation for Safer Work

Author’s Note: The first part of this five-part series (see https://incident-prevention.com/blog/when-the-system-isnt-enough-how-to-create-personal-motivation-that-saves-lives/) explored the notion of accepting 100% accountability for our safety at work. This article addresses mental preparation to reduce risk of serious injuries and fatalities. Part three will cover spiritual health, with a focus on clarifying and leveraging our own deeply held beliefs.

*****

Combat had endless tests, and one of the worst sins was “chattering” on the radio, which was reserved for essential messages; loose…

Batteries and the Hazard Communication Standard

Batteries have become a critical component of electric utility operations. Once limited to backup power in substations and control rooms, energy storage now drives innovation across the grid. As use of batteries increases, so does the responsibility to manage the unique chemical and physical hazards they introduce. Understanding how battery systems are governed under OSHA 29 CFR 1910.1200, “Hazard Communication,” is essential to ensuring worker safety, regulatory compliance and operational reliability.

Energy Storage and the HCS

Electric utilities sit at the center of the energy transitio…

What’s Your Bucket IQ?

I know a lot about buckets, but it wasn’t until after I hung up my tools that I learned much of what I’m going to share with you in this article.

Background

I was lucky to work as a lineman when I did. The buckets we used at Florida Power & Light through the 1970s were unlined, simple fiberglass Hi-Ranger platforms that got us close enough to the wire that we could hot-stick it. In my opinion, the Hi-Rangers of the ’60s and ’70s were the best bucket trucks ever built, and I know I’m not the only one who thinks so.

We didn’t glove at FPL back then, but when we started, I was the new…

‘Can I Be the Leader?’

Leadership continues to be a critical area of focus for utility safety and operations professionals. In my own career at Georgia Power, “Can I be the leader?” was a question I often asked myself and my employer. Now, in this installment of “Voice of Experience,” I am going to discuss the opportunities I was afforded during my 40-year journey with the company. My goal is to provide real-life insight into some of the industry leadership roles available while illustrating the passion and perseverance needed to safely, effectively guide our brothers and sisters through the workday.

What It Tak…

January-February 2026 Q&A

Q: We recently did some contract work in a manhole with live primary cables running through it. During an audit, the client’s safety team cited us for failure to have our manhole workers tied off to rescue lines. We had a tripod up and a winch ready for the three workers. What did we miss?

A: We have received similar questions over the years, usually due to a misunderstanding of OSHA’s enclosed spaces standard. Found at 29 CFR 1910.269(e) and printed below, the latest revision of the rules includes modified language. Look for the terms “safe work practices,” “enclosed space(s)” and “safe…

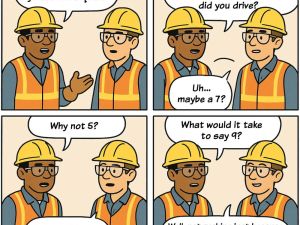

‘I Am a Good Putter’: What Golf Teaches Us About Safety Success

During my trip to Glendale, Arizona, for the most recent iP Utility Safety Conference & Expo, I received the single greatest piece of golf instruction I have ever heard. Now I want to share it with you, particularly as it relates to safety.

But first, you may be wondering how I obtained such outstanding advice while attending a safety conference. The iP staff hosted their welcome reception at Glendale’s PopStroke, billed as a “mini golf oasis,” and invited Art Eklund to deliver a putting lesson to attendees. Eklund is a Class A PGA Professional who currently works for the Phoenician Go…

6 Seasonal Strategies for Worker Well-Being

The holiday season is a time for family and celebration, but it is also one of the busiest times of year. Stress can easily creep in, creating safety hazards at work and at home. Staying mentally alert and focused during this period is key to preventing incidents.

Personal finances are among the most common seasonal stressors that can distract us during critical moments that demand our full attention. Time management, too, often becomes an issue in December as we push to meet year-end deadlines while juggling an assortment of social obligations. Disrupted schedules have the power to wreak…

Inspecting the Fifth Wire: Winning the War on Lineworker Suicide

Lineworkers confront daily risks many can’t imagine – arc flashes, falls, electrocutions and more. Yet there’s a silent, insidious threat currently claiming more lives in the electric utility industry than any physical injury.

We’re talking about suicide.

Safety professionals dedicate their careers to mitigating risk and preventing harm, understanding that serious injuries and fatalities devastate lives and ripple through the workforce. But what if the most devastating injury of all is one largely overlooked in traditional safety programs?

Industry employers already deliver tradition…

When the System Isn’t Enough: How to Create Personal Motivation That Saves Lives

Author’s Note: In this article – the first in a five-part series – we explore the notion of accepting 100% accountability for our safety at work, just as we do at home. This is an act of self-preservation. The hope is that management’s safety focus will overlap with our own preparation. We want as much overlap as possible.

The next article will address mental preparation, which is different than mental health. It’s a targeted focus to reduce risk of serious injuries and fatalities by improving our ability to remain self-aware and vigilant. We must keep our heads in the game.

When you’ve…

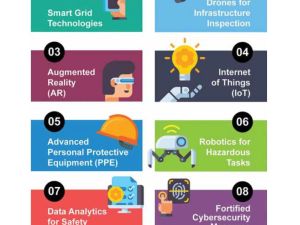

Forecasting the Future of Utility Safety: 10 Predictions for 2026 and Beyond

As we stand on the precipice of a new era in the utility sector, it is clear the future holds transformative potential driven by relentless technological progress.

We are already seeing not just small changes but a complete overhaul. The horizon is replete with innovations aimed at redefining safety protocols and operational efficiency. Predicted advancements – ranging from connected monitoring systems to augmented reality (AR) training to robotics – point to a not-so-far-off future in which advanced technologies will be essential to everyday utility operations.

In the remainder of this…