Substations

It is critical to have a good understanding of the substation requirements found within the OSHA standard.

Testing and Test Facilities

Electrical testing hazards arise when specialty testing is performed on electric power lines and equipment to determine maintenance needs and fitness for service. OSHA requirements for testing and test facilities are found at 29 CFR 1910.269(o) and 1926.963. Specialty testing refers to cable fault locating, large capacitive load tests, high-current fault closure tests, insulation-resistance and […]

Electrical Protective Equipment and Live-Line Tools

These items must be appropriately used and cared for to maintain their insulating capabilities. This article will address two unique areas of electric power regulatory standards: electrical protective equipment and live-line tools. As with all articles in this series, let’s start with the hazard. Electric power workers have exposure to electric shock hazards with extremely […]

OSHA Electric Power Standards – Simplified

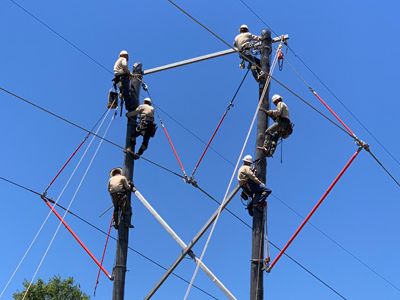

Overhead Lines Unique fall and electric shock hazards can occur during the installation and removal of lines and during tower and structure work. OSHA 29 CFR 1910.269(q) and 29 CFR 1926.964, both titled “Overhead lines and live-line barehand work,” address these hazards as well as the required controls for worker safety. Note: Live-line barehand work, […]

Mechanical Equipment Rules for Qualified Workers

Workers performing tasks involving mechanical equipment near energized power lines and equipment have exposure to hazardous step and touch potentials. In the preamble to OSHA 29 CFR 1910.269 and 1926 Subpart V, the agency describes 19 fatalities that involved derrick trucks, aerial lifts and other machines. These fatalities occurred when contact was made between live […]

OSHA Electric Power Standards – Simplified

Enclosed and Confined Spaces What’s the difference? The terms “enclosed” and “confined” seem like synonyms. When most of us think of something that is enclosed, we think of it as being confined, and when we think of a confined place, we think of it being somewhat enclosed. How we visualize these two words often accounts […]

OSHA Electric Power Standards – Simplified

Protection from Flames and Electric Arcs It is important to remember that all arc hazards are not equal. By Pam Tompkins, CUSP, CSP, and Matt Edmonds, CUSP, CIT, CHST According to OSHA, electric power generation, transmission and distribution workers face a significant risk of injury from burns due to electric arcs. Studies have concluded that […]

OSHA Electric Power Standards – Simplified | Part 6

De-energizing Lines and Equipment for the Protection of Employees

It’s critical for workers to understand the process of de-energizing lines and equipment to hold them clear.

Information Transfer: What’s Needed to Protect Affected Workers?

As with all the other articles in this series, when it comes to information transfer, it is important to start with the hazard. Individuals who work on or near electric power lines and equipment face a multitude of potential high-risk electrical hazards. Employers have the responsibility to identify and control known hazards to ensure worker […]

Minimum Approach Distances: What’s Required?

Let’s kick off this article with a definition of what “MAD” means in the utility sector – and it does not mean that we’re upset with you. The word is actually an acronym that stands for minimum approach distance, which is the calculated safe working distance that provides worker protection when working on or in […]

Why are Job Briefings and Risk Assessments Important?

When you hear the term “job briefing,” what comes to mind? Perhaps a meeting, a form to fill out or maybe even a complete waste of time? How we perceive job briefings has a huge impact on how we complete them. Per OSHA, job briefings are required to be completed before each job; however, for […]

What are OSHA’s Training Requirements?

In our first article in this series (see https://incident-prevention.com/blog/when-osha-electric-power-safety-standards-apply), we discussed how to apply OSHA’s electric power standards. This article will review OSHA 29 CFR 1910.269 and 1926 Subpart V training requirements relating to qualified and unqualified employees. To determine training requirements, you must first ask the question, are my employees exposed to electric power […]

When OSHA Electric Power Safety Standards Apply

Welcome to the first part of what will be a six-part series focused on OSHA’s electric power standards. We will start this series with a discussion about when the standards apply. Future articles will cover what is in the standards plus provide you with some practical ways to apply them. If you have tried to […]