Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend. The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compliance systems and paperwork were in place. Yet we […]

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a priority—it naturally drives improvements in quality, productivity, and overall operational excellence. By […]

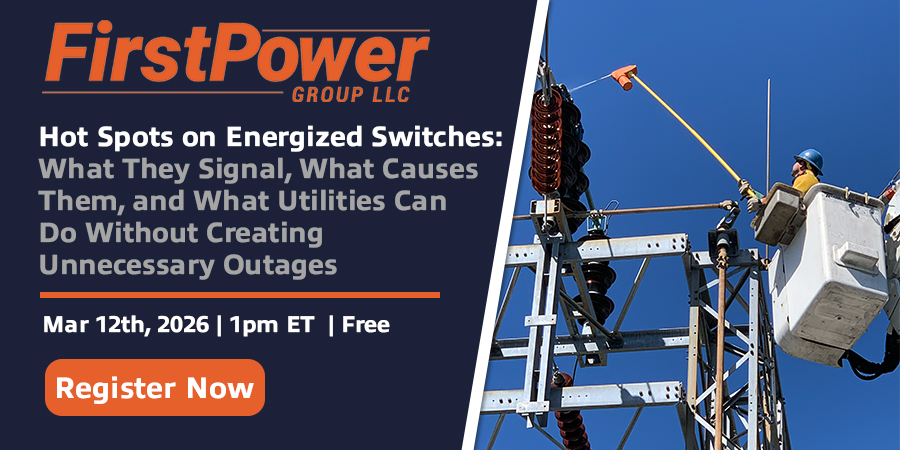

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

SPONSORED BY FIRSTPOWER GROUP

March 12th, 2026 @ 1PM ET

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Which will include:

- Hot Spot Interpretation: Understand that thermal anomalies signify underlying system failures, not just elevated temperatures.

- Root Cause Analysis: Identify primary drivers of hot spots, such as mechanical resistance, corrosion, contamination, and lubricant failure.

- Field Recognition: Recognize early physical warning signs in the field to prevent equipment escalation or failure.

- Mitigation Strategy: Evaluate critical decision points to determine if a fix requires an outage or can be handled while energized.

- Standardized Framework: Implement the Identify → Verify → Stabilize → Prevent workflow for consistent issue management.

- Maintenance Optimization: Adopt best practices in lubrication and record-keeping to minimize repeat issues and improve switch reliability.

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat stress and injury. The vest is constructed using the […]

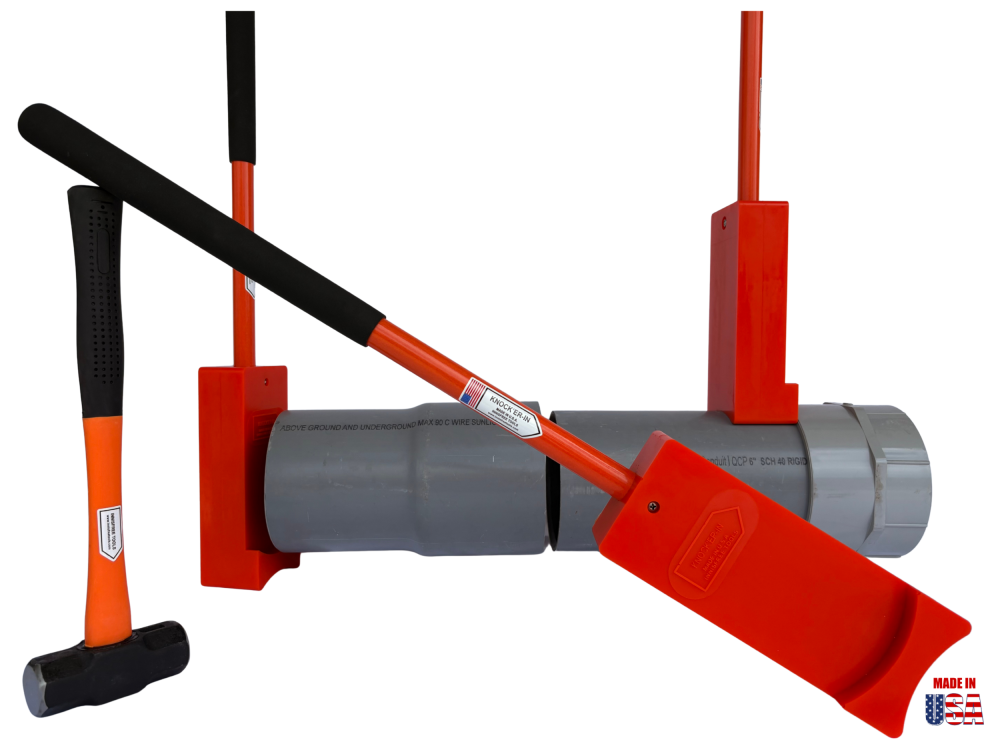

Underground Conduit Installation Tool

Prevent soft-tissue injuries, minimize struck-by incidents, and reduce sprains and strains with the KNOCK’ER-IN pipe and conduit installation tool from Innisfree. Offering an alternative to the traditional 2-x-4 method of joining UG conduit, this tool helps to increase worker safety, productivity and comfort, 10 feet at a time. The molded polyurethane block coupled with a […]

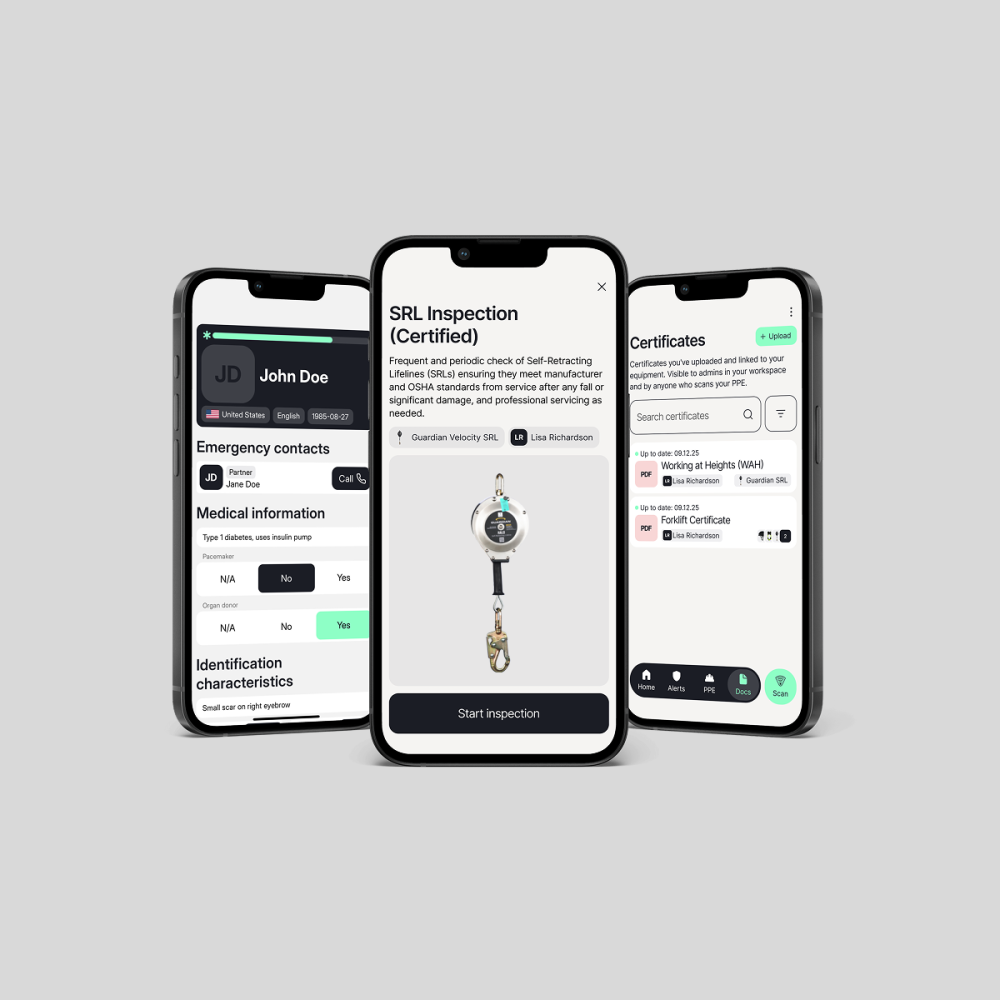

SRLs with Digital Safety Protection

Twiceme Technology, a company building the digital safety standard for jobsites and adventures, has expanded its partnership with height safety leader Guardian. Building on Twiceme’s existing integration in Guardian’s B7-Comfort Harness, it will now be integrated into 10 Guardian anchor-mounted self-retracting lifelines (SRLs), marking a first for the fall protection industry. The Twiceme-enabled SRLs from […]

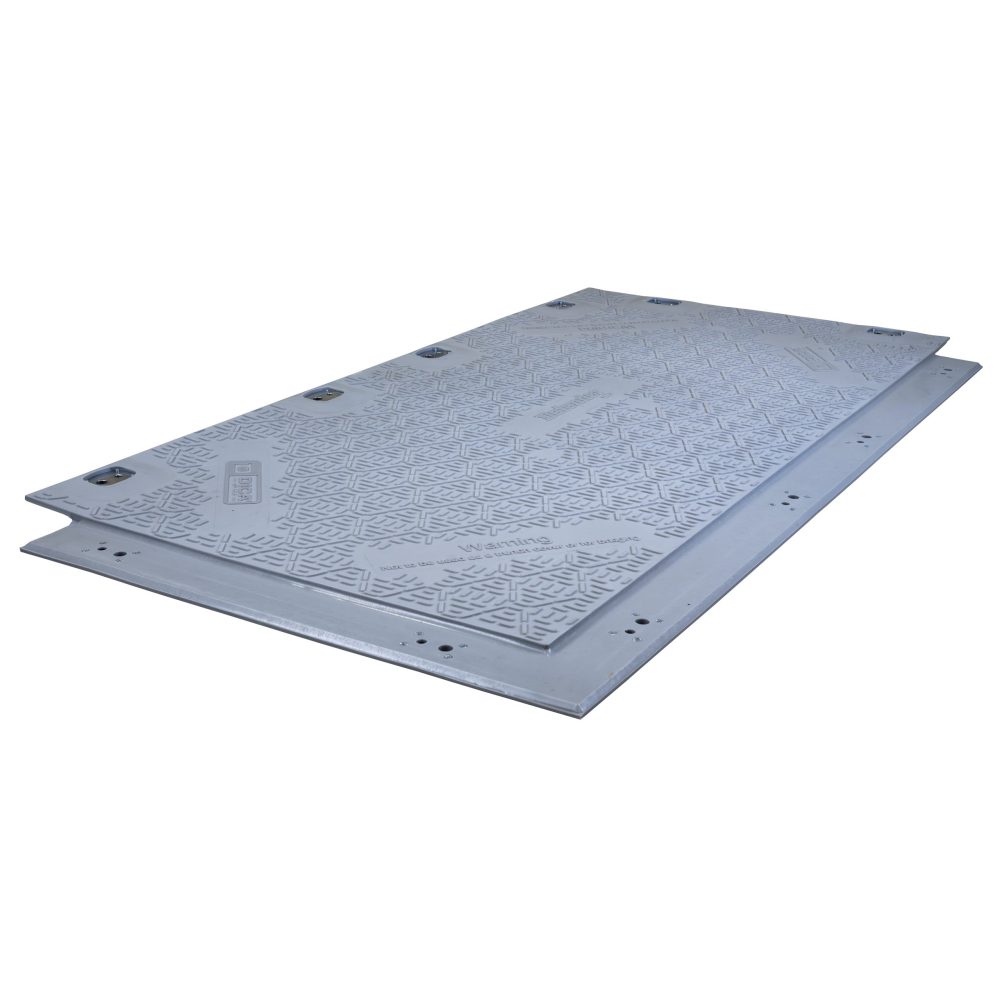

Ground Protection and Access Mats

DICA is expanding its product portfolio with the introduction of its own line of ground protection and site access mats. The new Ranger HD, Defender and Titan mats provide contractors with high-performance, cost-effective access options for a variety of jobsites. DICA will debut the company’s light-, medium- and heavy-duty mats in March at CONEXPO-CON/AGG 2026 […]

Self-Rescue System

The Buckingham 401SRK Self-Rescue System is an emergency descent device designed to allow workers to safely perform self-rescue from an elevated position when no third party is present. The system utilizes an all-aluminum descent control device (DCD) featuring an anti-panic brake that ensures a safe, controlled descent from an elevated surface. The DCD incorporates a […]

The Human Tuning Fork: Harnessing Frequency and Vibration for Utility Safety with Bill Martin, CUSP

In this episode of the Utility Safety Podcast, host Nick chats with Bill Martin, CUSP about a concept that goes far beyond the standard safety manual: the physics of human energy. Inspired by Nikola Tesla’s quote on energy, frequency, and vibration, Bill explains why workers are like “human tuning forks” and how one person’s attitude […]

Closing the Hazard Awareness Delay – Real-Time Grid Visibility with Active Grid Response

In this episode of Incident Prevention’s Utility Safety Podcast, host Kate Wade sits down with Tim Bedford, a 36-year veteran of PG&E and current Principal Customer Success Manager at Gridware. Together, they explore a critical new category of grid intelligence: Active Grid Response. Tim explains the concept of “Hazard Awareness Delay”—the dangerous gap in time […]

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our com…

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a priority—it naturally drives improvements in quality, productivity, and overall operational excellence. By utilizing Human and Organizational Performance (HOP) principles, the article highlights how a “safety-first” culture motivates employees to follow standards even when unobserved, ultimately reducin…

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

SPONSORED BY FIRSTPOWER GROUP March 12th, 2026 @ 1PM ET

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Which will include:

Hot Spot Interpretation: Understand that thermal anomalies signify underlying…

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat…

Underground Conduit Installation Tool

Prevent soft-tissue injuries, minimize struck-by incidents, and reduce sprains and strains with the KNOCK’ER-IN pipe and conduit installation tool from Innisfree. Offering an alternative to the traditional 2-x-4 method of joining UG conduit, this tool helps to increase worker safety, productivity and comfort, 10 feet at a time. The molded polyurethane block coupled with a fiberglass handle and rubber handgrip provides a cushion for every blow, while the positioning shoe offers stabilization through the strike. Additionally, the KNOCK’ER-IN features a concave arch bottom – because sometimes yo…

SRLs with Digital Safety Protection

Twiceme Technology, a company building the digital safety standard for jobsites and adventures, has expanded its partnership with height safety leader Guardian. Building on Twiceme’s existing integration in Guardian’s B7-Comfort Harness, it will now be integrated into 10 Guardian anchor-mounted sel…

Ground Protection and Access Mats

DICA is expanding its product portfolio with the introduction of its own line of ground protection and site access mats. The new Ranger HD, Defender and Titan mats provide contractors with high-performance, cost-effective access options for a variety of jobsites. DICA will debut the company’s light…

Self-Rescue System

The Buckingham 401SRK Self-Rescue System is an emergency descent device designed to allow workers to safely perform self-rescue from an elevated position when no third party is present. The system utilizes an all-aluminum descent control device (DCD) featuring an anti-panic brake that ensures a saf…

The Human Tuning Fork: Harnessing Frequency and Vibration for Utility Safety with Bill Martin, CUSP

In this episode of the Utility Safety Podcast, host Nick chats with Bill Martin, CUSP about a concept that goes far beyond the standard safety manual: the physics of human energy. Inspired by Nikola Tesla’s quote on energy, frequency, and vibration, Bill explains why workers are like “human tun…

Opinion

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

Stephen Shutt, CUSP

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

Podbean Account

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Nick Leonardi

Medical-Grade Cooling Vest

Kate Wade

Video

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend. The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compli…

Featured Topics

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our com…

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a prio…

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

SPONSORED BY FIRSTPOWER GROUP March 12th, 2026 @ 1PM ET

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Which will include:

Hot Spot Interpretation: Understand that thermal anomalies signify underlying…

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat…

Underground Conduit Installation Tool

Prevent soft-tissue injuries, minimize struck-by incidents, and reduce sprains and strains with the KNOCK’ER-IN pipe and conduit installation tool from Innisfree. Offering an alternative to the traditional 2-x-4 method of joining UG conduit, this tool helps to increase worker safety, productivity a…

SRLs with Digital Safety Protection

Twiceme Technology, a company building the digital safety standard for jobsites and adventures, has expanded its partnership with height safety leader Guardian. Building on Twiceme’s existing integration in Guardian’s B7-Comfort Harness, it will now be integrated into 10 Guardian anchor-mounted sel…

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our compliance systems and paperwork were in place. Yet we still failed our brothers and sisters.

That reality should eat at all of us because our industry could have done better then – and we should be doing better now. We must face the truth that not all safety methods work as intended. Without adjusting our approach, elimination of serious injuries and fatalities (SIFs) is nearly impossible.

The Illusion of Safety

One specific thing that keeps me up at night is the illusion of safety. Many of us are drowning in paperwork, but it is not meaningfully moving the needle in terms of SIF prevention.

Think about it. Nearly every incident we investigate circles back to either a lack of clarity or a lack of communication. Both are preventable forms of confusion. In allowing uncertainty to linger, we accept far greater risk than the cost of slowing down or stopping work to make things right.

Compliance is a science. It’s measurable, rigid, written in black and white. Regulatory and organizational rules tell us what’s permitted and what isn’t, what will pass an audit and what won’t. Safety, on the other hand, is an art. It’s dynamic, fluid, constantly changing. Because each jobsite is different, frontline workers must assess changing site conditions to identify hazards, applying what they’ve learned from their safety and compliance training to mitigate harm. This skill requires a combination of creativity, discipline and situational awareness in real time.

Unfortunately, the industry often considers compliance and safety as one and the same – and that’s a problem.

Job hazard analyses and pre-job briefings should never be treated solely as company-mandated compliance measures. Time spent on these activities should be dedicated to ensuring frontline employees truly understand the work and hazards ahead. Job forms signed without worker understanding are much like shields crafted from cheap paper: easily torn and ignored, potentially exposing users to fatal hazards.

The Courtroom vs. the Pole

Here’s another hard truth: While compliance measures often protect employers in courtrooms, that’s not necessarily the case for lineworkers.

Completed job forms help employers demonstrate to judges and juries that they fulfilled their legal obligations. But as any lineworker suspended 45 feet in the air will tell you, a signed job form will never support their weight as they work or prevent them or their coworker from making a potentially fatal error.

Sadly, some organizations have weaponized compliance paperwork, using it as grounds for discipline or termination. Yet it is critical to note here that compliance is not our enemy. This is about perspective. By viewing compliance as a safety tool rather than our end goal, we can focus on what we should be aiming at: sending workers home in the same condition they arrived in (or better).

Keep in mind that workers who believe safety rules and paperwork exist only to protect their employer will almost always sign their forms, nod during meetings and walk away unchanged – and likely unwilling to change.

Leadership Sets the Tone

This is an industry problem. Leadership sets the tone. Executives who speak about safety purely as a compliance metric send a message to crews, loud and clear, that employer liability concerns matter more than employee lives. When production is pushed at all costs, workers are taught that safety rules aren’t rules; they’re suggestions.

Good, strong leadership looks different. These executives invest in clarity and measure safety by how many workers return home uninjured, not the number of forms completed.

The fix to our industry’s safety culture is not complicated, but it requires courageous leaders who are willing to (1) prioritize employee understanding over signed job forms; (2) treat compliance paperwork as a living tool; (3) measure safety by outcomes, not optics; and (4) create organizational cultures in which workers believe the system exists to protect them.

Let’s stop pretending that more rules will save us. What we need is greater clarity, accountability and humanity in our approach. Safety is about people, not paperwork – but until we consistently treat it that way, we will keep paying the price.

About the Author: Stephen Shutt, CUSP, serves as an instructor and the director of powerline programs for Heavy Equipment Colleges of America. Reach him at stephen.shutt@hecofa.com.

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a priority—it naturally drives improvements in quality, productivity, and overall operational excellence. By utilizing Human and Organizational Performance (HOP) principles, the article highlights how a “safety-first” culture motivates employees to follow standards even when unobserved, ultimately reducing rework and fostering a more efficient workforce.

Read the article by Doug Hill, CUSP – Built In, Not Bolted On: Using Safety to Drive Operational Excellence

Key Takeaways

- Safety as a Value, Not a Priority: Priorities can shift depending on the day’s demands, but values remain constant. When safety is a value, employees adhere to standards because they see the inherent worth in them.

- The Interconnectivity of Success: Safety, quality, and productivity are not silos. A safe process is often a high-quality process that leads to productive outcomes.

- Human and Organizational Performance (HOP): Systems should be designed so that processes are easy to follow and make sense to the people actually doing the work.

- The Power of “Why”: Employees are more likely to follow protocols (like wearing PPE) when they understand the personal stakes (family, health, well-being) rather than just trying to avoid a reprimand.

- Learning from Success: Organizations should focus on learning from what goes right just as much as they learn from failures to identify opportunities for continuous improvement.

3 Questions and Answers

Q1: What is the main difference between safety being a “priority” versus a “value”? A1: A priority is something that can change based on circumstances or pressure (like a deadline), whereas a value is a core belief that remains constant regardless of the situation. When safety is a value, it is integrated into every action naturally. Q2: How does the article suggest safety impacts productivity and quality? A2: The author uses the analogy of building a child’s bicycle: because you care about the safety of the rider, you follow instructions more carefully (Quality), which ensures the bike works correctly the first time and doesn’t require repairs (Productivity/Efficiency). Q3: Why is “peer-to-peer support” mentioned as a critical factor in safety culture? A3: Because supervisors cannot be everywhere at once. A strong safety culture relies on workers looking out for one another and holding each other accountable to standards even when leadership is not present. #UtilitySafety #OperationalExcellence #OccupationalSafety #HOP #WorkplaceCulture #IncidentPrevention Subscribe to Incident Prevention Magazine – https://incident-prevention.com/subscribe-now/ Register for the iP Utility Safety Conference & Expo – https://utilitysafetyconference.com/Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

— Webinar Sponsored By —

“Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages”

** THIS WEBINAR WILL BE RECORDED **

Be sure to register. If you are unable to attend on the day of this event, you will still receive a link to the webinar recording afterwards so that you can access and view it at your convenience.

Join the Conversation With Industry Experts On March 12th at 1:00 p.m. ET

Hot spots on energized switches are often treated as isolated temperature issues, but in reality, they can be early warning sign…

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat stress and injury.

The vest is constructed using the same proven technology as the FDA-approved CarbonCool system, which offers ultra-compact, rapidly deployable cooling performance that exceeds full ice-bath immersion with no need for ice, water or electricity. CarbonCool is an entirely dry cooling technology that is compatible with other medical interventions, including AEDs and diagnostic imaging.

To meet the demands of high-risk industrial environments, EMCOOLS recently introduced a flame-resistant ArcticCore Vest that complies with NFPA 2112, enabling safe deployment in settings where fire hazards exist.

The EMCOOLS ArcticCore Vest is also available with an optional hydration bladder, which can be frozen to extend the cooling duration while providing on-the-go hydration.

Email Global Healthcare SG (info@globalhealthcare.sg) or EMCOOLS (info@emcools.com) for clinical and peer-reviewed studies, OSHA guidance and demos. www.globalhealthcare.sg, https://emcools.com

Underground Conduit Installation Tool

Prevent soft-tissue injuries, minimize struck-by incidents, and reduce sprains and strains with the KNOCK’ER-IN pipe and conduit installation tool from Innisfree. Offering an alternative to the traditional 2-x-4 method of joining UG conduit, this tool helps to increase worker safety, productivity and comfort, 10 feet at a time. The molded polyurethane block coupled with a fiberglass handle and rubber handgrip provides a cushion for every blow, while the positioning shoe offers stabilization through the strike. Additionally, the KNOCK’ER-IN features a concave arch bottom – because sometimes you need to knock’er-off. www.innisfreetools.com

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our com…

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a prio…

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

SPONSORED BY FIRSTPOWER GROUP March 12th, 2026 @ 1PM ET

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Which will include:

Hot Spot Interpretation: Understand that thermal anomalies signify underlying…

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat…

Unsafe Compliance: Why Checking Boxes Won’t Save Lives

In the nearly 15 years I’ve worked in the electric utility industry, I’ve witnessed life-altering injuries and helped to bury more than one coworker-turned-friend.

The toughest part for me to accept is knowing that most of those injuries and deaths were preventable. We were well-trained. Our com…

Utility Safety Podcast – Deep Dive – Using Safety to Drive Operational Excellence – Written By Doug Hill, CUSP

“Built In, Not Bolted On” explores the critical integration of safety into the core of organizational operations rather than treating it as a secondary, compliance-based add-on. Author Doug Hill argues that when safety is established as a fundamental organizational value—rather than just a prio…

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

SPONSORED BY FIRSTPOWER GROUP March 12th, 2026 @ 1PM ET

Hot Spots on Energized Switches: What They Signal, What Causes Them, and What Utilities Can Do Without Creating Unnecessary Outages

Which will include:

Hot Spot Interpretation: Understand that thermal anomalies signify underlying…

Medical-Grade Cooling Vest

The EMCOOLS ArcticCore Vest from Global Healthcare, a world leader in medical cooling technology, is powered by HypoCarbon to deliver deep-core cooling – not merely surface-level relief. By penetrating body tissue to lower the user’s core temperature for over four hours, it aids in preventing heat…

Most Popular

We use cookies and similar technologies to improve your experience on our website.