The Globally Harmonized System for Classifying and Labeling Chemicals

The Globally Harmonized System (GHS) is a worldwide system for communicating chemical hazards. It is a common approach to defining and classifying hazards for chemicals, and communicating such information on labels and safety data sheets to employees and users of chemicals. The GHS itself is not a regulation or a standard; the system was founded based on an international recommendation from the United Nations and recently was adopted into OSHA regulations. Additions and changes were made in 29 CFR 1910.1200, commonly known as the Hazard Communication standard or the right-to-know law.

OSHA’s adoption of the GHS has resulted in setting action timelines for U.S. manufacturers, distributors and employers. The first action point for employers under the new GHS is to conduct employee training by December 1, 2013.

OSHA’s intent in adopting the GHS is to improve consistency in hazard communication because of the global market for chemicals. The 16-point format for the new safety data sheets will standardize chemical information for consistency and easy-to-find information. The GHS’ nine pictograms aim to convey specific information in an easily identifiable symbol depicting the hazards of the chemical. All of the pictograms will be bordered by a red diamond frame around the symbol that represents the hazard. Any chemical substance can have one or several pictograms to represent the different specific hazards.

Major Changes to the Hazard Communication Standard

With the introduction of the GHS, the following changes to the Hazard Communication standard will occur:

• Hazard classification will provide specific criteria for classification of health and physical hazards as well as classification of mixtures.

• Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided.

• Safety data sheets will have a specified 16-section format.

• The Hazard Communication standard will require that workers are trained within two years of the publication of the final rule to facilitate recognition and understanding of the new labels and safety data sheets.

Numerical Categorization Changes and Conflicts

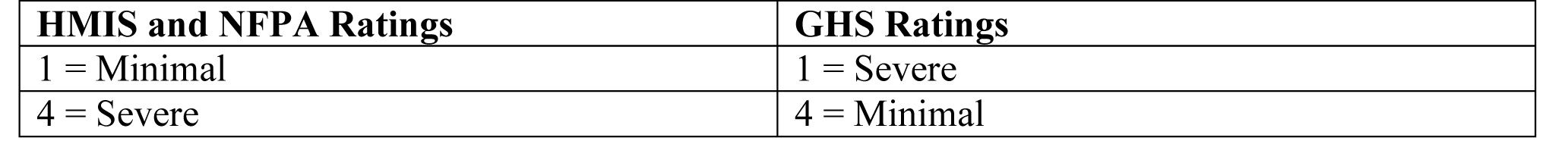

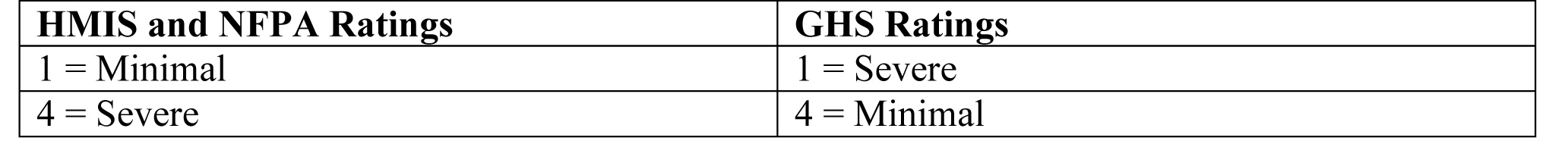

One of the most important changes that has come about under the adoption of the GHS into the Hazard Communication standard is the definition of “flammable.” Notice that under the GHS system, the category numbers go from low to high with lower numbers being more severe. This is exactly opposite with the Hazardous Material Information System (HMIS) and NFPA system we have used in the past with the numbering system of the NFPA 704 placard. Under the NFPA 704 placarding system, flammable rating 1 represented a minimal risk; under the new GHS system, 1 represents the highest risk or severe rating.

Under the new GHS definitions for flammables, flash points have been changed and are no longer consistent and in alignment with the NFPA definitions. All employees need to be able to identify and understand both the GHS and the NFPA definitions for flammables. For your reference, here is a breakdown of the GHS categories:

• Category 1: Flash point <=73.4 F and boiling point <=95 F = danger, extremely flammable liquid and vapor.

• Category 2: Flash point <=73.4 F and boiling point >95 F = danger, highly flammable liquid and vapor.

• Category 3: Flash point >73.4 F and <=140 F = warning, flammable liquid and vapor.

• Category 4: Flash point >140 F and <=199.4 F = warning.

Another change under the GHS is that the terminology “safety data sheets” is now being used instead of “material safety data sheets.” The format is standardized as follows: 1. Identification; 2. Hazards identification; 3. Composition/information on ingredients; 4. First aid measures; 5. Firefighting measures; 6. Accidental release measures; 7. Handling and storage; 8. Exposure controls/personal protection; 9. Physical and chemical properties; 10. Stability and reactivity; 11. Toxicological information; 12. Ecological information; 13. Disposal considerations; 14. Transport information; 15. Regulatory information; and 16. Other information. Note: Sections 12-15 are considered nonmandatory under the OSHA proposal.

About the Author: Lt. Col. Charles R. Southerland, CSC, CUSP, is director of management services for Morristown Utility Systems. He has worked in the utility industry for more than 35 years in a variety of capacities and has earned numerous safety certificates from the EPA, OSHA and FEMA. Southerland also acts as a consultant for Tennessee Valley Public Power Association and served as an instructor for the Tennessee Emergency Management Agency.