The Health and Safety Plan: A Project Management Tool

The more well-developed a HASP is, the more useful it can be as a safety resource for project personnel.

A health and safety plan, or HASP, can be a valuable project management tool. It is a working document intended to help prevent workplace injuries, illnesses and deaths, as well as equipment and facility damage, by detailing the tasks involved in a project, identifying the project’s specific hazards and describing all mitigation procedures to be implemented.

In this article, we will review some of the most important sections to be included in a HASP: hazard identification and controls; the general project work plan; emergency response; incident reporting; communications; regulatory compliance; and technical safety requirements.

Hazard Identification and Controls

A good HASP will identify the project’s personnel – including the project management team, foreman, competent persons, and employees with specialized skills and credentials needed for the job – as well as their roles, responsibilities, qualifications and contact information.

It will also include a detailed, project-specific work plan of the tasks to be completed, along with the related risk assessments, identification of hazards, and controls to be implemented. Note that project tasks can run the gamut. Examples include demolition; material handling and storage; excavation; shoring; concrete work; hot work; pole setting; electrical installation and repairs; conduit installation; bus work; rigging; cable/wire pulling; directional drilling; chemical use; confined/enclosed space entry; scaffold setup and use; and traffic control.

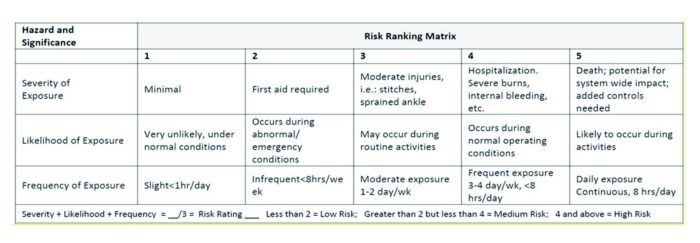

The portion of the HASP that focuses on hazard identification should identify physical and health hazards that could harm workers – such as falls from height and chemical exposures – as well as the severity of those hazards. For instance, contractors could use either a high/medium/low determination or a numerical rating matrix; the matrix is a chart that indicates probability and severity for project tasks to be performed. See the example below.

Sample of a Numerical Rating Matrix

Upon a thorough assessment of the potential physical and health hazards, the HASP should capture a list of all procedures that will be used to remove or control the known hazards.

General Project Work Plan

A portion of the HASP should include the general project work plan. For this section, the contractor should list all the major steps in the project – including mobilization, administrative tasks, work-site orientation meetings and equipment inspections – that may not have been included in the hazard identification and risk assessment section.

As work progresses, it may be necessary to add or make changes to the tasks and controls. Any significant changes to the scope of work, work practices and/or site conditions must be evaluated for new hazards and their associated risks. As necessary, new controls must be identified and documented. The HASP should be amended for significant site-specific changes. Any such changes to the job should be reviewed by project personnel and documented in the HASP as addendums. If a change is both temporary and minor, the new information may be documented in the job brief/tailgate talk and conveyed to workers.

You may also want to include a section in the HASP regarding company requirements, which details any information that the company feels would be beneficial to workers on-site, such as their own procedures or work instructions.

Emergency Response

Emergency response is arguably one of the most important sections of a HASP. This section should identify project personnel trained in first aid/CPR, fire extinguisher use, chemical spill control and confined/enclosed space rescue. Note that crews of at least two workers are required in some circumstances so that one worker can provide first aid or CPR to the other if necessary.

This section should also include an emergency action plan to address any potential crisis events, including those involving injury to a worker, chemical exposure, damaged facilities, a fire or explosion, and extreme weather events. It is highly encouraged to include individual response plans for different types of emergencies in this section. These response plans could include a chemical spill control plan, a confined/enclosed space rescue plan and/or a mobile elevating work platform rescue plan.

In particular, a confined/enclosed space rescue plan is needed when work occurs in an area where emergency medical personnel may not be able to respond in a timely manner. OSHA regulations are explicit about the evaluation and effectiveness of a timely response to confined space emergencies.

Further, the location of and directions to the closest emergency medical facility should be included in this section, and this information can also be included in an appendix at the end of the HASP. Keep in mind that it’s important to determine before a project begins whether the closest medical facility will be able to provide care for all levels of trauma. If a worker sustains a severe injury, and the local hospital can’t provide the necessary level of care, the worker is in greater danger of succumbing to their injury.

While we’re discussing HASP appendices, you may want to consider including an appendix for each of the following:

Contact information for contractor and host personnel.

An emergency action plan that illustrates exit routes and muster areas.

HASP review attendance sheets, which document that the HASP was reviewed by project workers.

Incident Reporting and Communications

A HASP should outline the timely reporting of project-related incidents – including near-misses – as well as the investigation steps that must be taken if an incident occurs. When analyzing an incident, the current best practice is to first establish all the factors that contributed to the event and then determine the root cause, with the primary goal of preventing recurrence.

Communication of safety initiatives is another important section of a HASP, allowing for a record of these important communications among project team members. All team members should review the contents of the HASP before the project begins, whenever a significant change occurs and when new workers join the crew.

Regulatory Compliance and Technical Safety Requirements

A good HASP section on safety and environmental compliance will feature a description of how the contractor will monitor compliance with regulatory requirements, their own standards and the host’s requirements. For example, the contractor could summarize routine assessments, participation in safety observation tours, reasons for a worker’s dismissal for safety violations, assessment reports and responses to compliance issues.

Contractors must comply with all environmental regulations, permit conditions and restrictions. Compliance should be established in accordance with host requirements and governmental regulations. It may also be beneficial for the contractor to briefly address in the HASP how environmental compliance will be maintained. Host representatives are responsible for monitoring environmental conditions during the project and ensuring deficiencies and emergencies are handled appropriately.

A final section to include in the HASP focuses on the host’s technical safety requirements. This section outlines specific rules and work practices that are unique to the host’s operations. Contractors could be subject to some or all of these requirements depending on the work. Including this section in the HASP helps to ensure the information is available to workers on-site. Examples of requirements that may need to be addressed include specific PPE requirements; isolation of energized apparatus; use of safety observers; and work zone traffic control.

Conclusion

A well-constructed HASP is a valuable project management tool for both the contractor and host. It provides the host with a chance to assess the contractor’s plan for a safe workplace that protects employees and facilities against potential hazards. The HASP also affords the host the opportunity to challenge the contractor and mandate better worker and facility protections. Lastly, it provides documentation of important information that can be accessed by workers on the job.

A HASP does not guarantee a job site free of unwanted events, but the likelihood of an event is minimized if all parties are aware of the hazards and know the mitigation plans.

About the Author: Charles Keeling, CUSP, is a 35-year safety professional in general industry and construction. He is also a certified New York State Workplace Safety Consultant. Keeling earned a bachelor’s degree in fire and emergency management and currently works with PSEG Long Island conducting safety and regulatory compliance duties. He also serves as the ASSP Region VIII metro area director. Reach him at charles.keeling@pseg.com.