Equipotential Grounding for URD Work

I have written about grounding for the protection of employees numerous times in Incident Prevention magazine, addressing both the law and other issues. Let’s begin this installment with the understanding that “grounding for the protection of employees” – which is the phrase OSHA uses – means establishing an equipotential zone or EPZ. The purpose of grounding is to trip circuits. Grounding for the protection of employees can only be assured if it is arranged in an equipotential manner, preventing the worker from being exposed to a hazardous difference in potential. That’s the bottom line, and as I stated in the April-May 2025 issue of iP, equipotential grounding is the law (see https://incident-prevention.com/blog/equipotential-grounding-is-the-law/).

By the way, I reference OSHA 29 CFR 1910.269, part of the General Industry standards, throughout this text. Readers should note that the rules are exactly the same in the 1926.962 Construction standard.

The EPZ Challenge for URD

Now, let’s talk about the difficulty of creating an EPZ for workers in underground residential distribution (URD), which is not exempt from OSHA’s grounding rules. As paragraph 1910.269(n)(3), “Equipotential zone,” states, “Temporary protective grounds shall be placed at such locations and arranged in such a manner that the employer can demonstrate will prevent each employee from being exposed to hazardous differences in electric potential.” There are no exceptions.

But when it comes to URD, especially repairing a cable or replacing elbows or terminators, it’s impossible to create an EPZ by simply arranging ground connections. However, we do have an option found at 1910.269(n)(2), which, after spelling out the requirements for proper switching, states the following: “… [the employer] shall ensure proper grounding of the lines or equipment as specified in paragraphs (n)(3) through (n)(8) of this section. However, if the employer can demonstrate that installation of a ground is impracticable or that the conditions resulting from the installation of a ground would present greater hazards to employees than working without grounds, the lines and equipment may be treated as deenergized provided that the employer establishes that all of the following conditions apply: The employer ensures that the lines and equipment are deenergized under the provisions of paragraph (m) of this section; there is no possibility of contact with another energized source; and the hazard of induced voltage is not present.”

Paragraph 1910.269(n)(2) requires use of equipotential grounding to protect the employee, or the employer must meet the conditions of isolation to prevent employee exposure to any potential that could create an electrical hazard.

Here’s the issue, which will likely ring true with many iP readers. We have crews working URD with no consideration given to what would happen if the URD circuit were inadvertently energized. Maybe even worse, no consideration is given to the presence of neutral current flowing in the URD system. Here is my prime example: There is not an overhead crew in the industry – at least I hope not – who would approach an overhead distribution system, put a system neutral in a hoist, cut that system neutral and then grab both cut ends barehanded. Such an act would expose a worker to an open neutral circuit and the possibility of system voltage in that open. In reality, the voltage in the open neutral is low because we have multigrounded neutral systems. It must be high enough to break the resistance of your skin; if that happened, neutral current would flow through your body. Nobody is going to take that chance. In the past, whenever I took my crew to a job that required opening a neutral, we had detailed discussions about how to mach out the neutral and the hazard to be prevented. Yet a crew who just went through a similar exercise with the overhead neutral will then go work a URD cable repair job in a ditch and reconnect the concentric system neutral with their bare hands.

What’s Really Happening?

Part of the issue is that very few people know of someone being shocked or electrocuted during a concentric neutral repair – but it does happen. Employees in a ditch or working at night will begin reassembling a concentric connection and see a little spark when the conductors touch. That spark tells the tale. It wouldn’t exist if there were no difference in potential. The difference is created by a combination of (1) the distance between the open concentric and the remote ground and (2) the current that is being picked up by the concentric neutral when they touch.

You may be asking, “Why don’t we get shocked?” The answer is the 50-volt buffer, which isn’t actually 50 volts. It’s just universally accepted that 50 volts is the natural average resistance of human skin. That value has evolved from Charles Dalziel’s work on the effects of electrical current on the human body. In the margins of his reporting, Dalziel noted that some of his test subjects required a higher voltage than others to expose them to current flow. The 50-volt resistance is also supplemented by other forms of resistance that a worker is wearing, such as boots and leather gloves. If the voltage cannot penetrate the resistance of a worker’s skin, current can’t flow, and the worker won’t be hurt. The fact is, every time you get between a concentric neutral, you have exposed yourself to a potential difference between the two cut ends that simply wasn’t high enough to penetrate your skin and allow current to flow through your body.

So, if it’s an open neutral, why isn’t the voltage high? The answer is that a multigrounded system created incidental protection. If I’m working on phase B of a community three-phase URD system, phases A and C are parallel to phase B. If phases A and C are intact, they create a remote bond across my open phase-B concentric. In addition, at each transformer on either side of my open, there is a ground rod tying the concentric to earth. URD workers have benefited from this incidental protection since the first URD trouble job was issued.

No Simple Solution

Can you trust this protection? Under normal conditions, it appears to be universally but conditionally protective. If the URD system were exposed to a fault anywhere on the URD and/or overhead feed system, the resulting ground fault on the concentric would likely create a high potential difference between the concentric and the earth the worker is standing on.

The problem here is that there is no simple solution, particularly if the phase conductors are exposed, such as during an elbow or pothead terminator change or in the middle of stripping cable, even if it’s grounded at both ends. Grounding at a remote end of the cable produces a potential difference between that remote ground and the local ground the worker is standing on. The only way to equalize those potentials is to strip the cable down to the phase and attach a ground to an equipotential mat, which, of course, isn’t possible.

This is where the 1910.269(n)(2) “installation of a ground is impracticable” provisions come in. Isolation is the only true solution. It’s used in overhead all the time. If I open a set of switches and have a visible open, the conductor between those two visible opens is no longer dangerous given the (n)(2) provisions that it cannot become energized, that it’s not subject to any other mode of energizing and that the isolated conductor isn’t exposed to an induction hazard.

For continued discussion of URD isolation, see “Worker protection while working de-energized underground distribution systems” (see https://ieeexplore.ieee.org/document/1256391), available through IEEE for a fee.

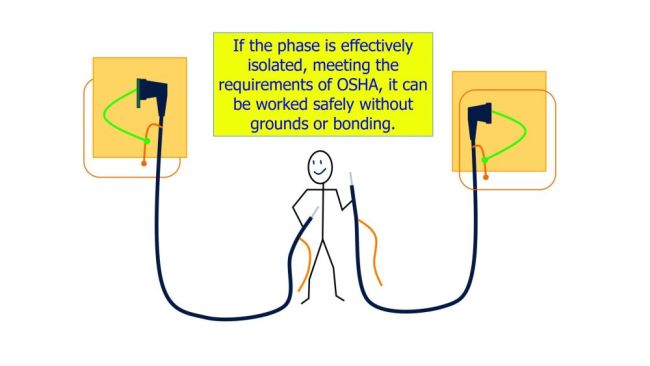

Visual Explanations

I’ve included three visual explanations on these pages demonstrating what happens when we isolate or attempt to isolate a URD cable. Since I can’t cover every isolation mode, I’m going to use the simplest one, which is incorporating the grounding bushing method you’re using to ground the remote end of a cable (see Image 1). Install the grounding bushing in the conventional manner and close the elbow. You’ve now confirmed that the cable is de-energized by a voltage check and the presence of a ground. When installing the grounding bushing, make the ground lead connection to the concentric lead on the elbow that you’re grounding. Once you’ve confirmed the condition of the cable, you must do two things: (1) lift the ground bushing out of the holding bracket in the enclosure and (2) cut the concentric below the ground lead, isolating it from the ring bond in the transformer, pad or switchgear. Using this method, you’ve totally isolated the cable, and you’ve put the phase conductor in series with the concentric, eliminating any possibility of capacitance on the cable.

Using the example of our phase-B trouble call, one problem is that, if any system abnormalities exist – like unintended opens in the concentric on phase A or C – cutting a concentric could interrupt the system neutral for the rest of the circuit. Usually, a simple amp clamp test can be conducted to determine potential issues. If all three concentrics are continuous, take an amp current reading at a three-phase takeoff or a switch pad. You should find current on all three concentrics, indicating continuity. To ensure total isolation, drop a blanket over the isolated terminator so that you don’t create contact between the concentric and other parts of the system when you close the cabinet or pad.

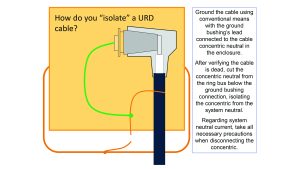

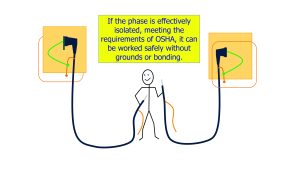

Images 2 and 3 are used in the Institute for Safety in Powerline Construction’s personal protective grounding training protocols. iP is not offering them as mandatory solutions or recommendations. We are identifying the hazards and explaining how employers can effectively teach crews about them. Note that I am the author of all three images and give readers full authorization to use them in your training if you feel they could be helpful.

Image 2 demonstrates the electrical properties of isolating a URD cable as previously explained. On each end of the cable, the concentric has been cut free of the ring bond, putting the phase conductor in the elbow in series with the concentric on the cable. In addition, the elbow is draped with an orange blanket, but a 4-kV blanket would probably suffice. Now, look at the worker in the ditch, who’s holding a cable in each hand. The concentrics are not connected. Even if they were connected, no risk would exist for the worker because the concentrics are isolated at the remote end of the cable.

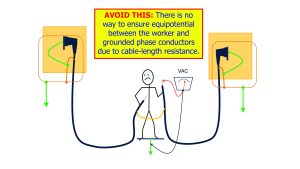

In Image 3, one small change creates an element of risk if it’s not properly understood. You can see that the concentric is still connected to the ring bond at each remote end of the cable. In this configuration, the phase conductor and concentric are still in series with each other. Additionally, the open phase conductor in the worker’s hands is parallel with the concentric. When the concentric is connected, it creates a bonding bridge across the open phase conductor. However, the concentric neutral bond will not be at the same potential as the open phase conductors because of the length of the cable, producing a resistance. It’s quite likely that, under normal conditions, the voltage between the open phase conductors would be very low, but there’s no telling what the potential difference could be in the event of a system fault. Image 3 also provides a visual representation (the meter) of the potential difference between the earth at the worker’s feet and the remotely grounded phase conductor.

Conclusion

The issues with URD grounding are complex, but we can’t ignore the potential for serious injury. The whole reason we ground a cable is because we think an undesirable event could occur. If we think an undesirable event could occur, why should our preparation only be half-complete? Understand the principle of current flow in the grounded URD system and consider isolation as an effective means of protecting our employees.

About the Author: After 25 years as a transmission-distribution lineman and foreman, Jim Vaughn, CUSP, has devoted the last 28 years to safety and training. A noted author, trainer and lecturer, he is a senior consultant for the Institute for Safety in Powerline Construction. He can be reached at jim@ispconline.com.