‘The Worst Day of My Life’

A retired lineman recalls details and lessons learned from an electrical contact that killed his best friend.

This story is about a devastating accident that took the life of one of my best friends many years ago. I have always been somewhat reluctant to speak or write about it because dealing with my friend’s family in the aftermath of his death was extremely painful. As time has marched on, however, I’ve found myself thinking it’s time to share the details of the accident with other lineworkers in hopes of helping them avoid and prevent similar accidents in the future.

Background

During my high school years in Salinas, California, I became friends with a fellow student by the name of David White. We became close over time, playing football and hunting together, among other activities. After high school, we were both hired as groundmen by a local utility company. We progressed through our apprenticeships together and, in 1963, became journeymen linemen at the same time.

Off the job, our families frequently spent time together. Jane, David’s wife, was employed as an X-ray technician at a hospital in Salinas; together they had a son who was about 3 years old at the time of this story. David’s father also worked for the local utility company for many years, eventually advancing to the position of customer services supervisor.

Our career paths split after David and I had worked as linemen for a few years. I became a line foreman while David became a troubleman. At that time, the utility company’s troublemen worked alone performing a variety of tasks, such as switching, setting meters and investigating customer problems. Each troubleman was assigned a geographic area of the company’s service territory.

On the day of the accident, my crew and I were installing underground cables for a new commercial development in North Salinas. Around 2 p.m., the line superintendent was visiting my job site to discuss the progress of the job. While we were talking, he received a call from the dispatcher, who explained that a customer had called to say that he’d observed a utility worker hanging from a pole near Zabala Road. The dispatcher also stated that earlier in the day, he had dispatched David White to investigate a power outage to an irrigation pump in the area.

After hearing all this, I immediately threw my lineman tools and a handline into the back of the superintendent’s pickup truck. The two of us then headed off toward Zabala Road.

Arrival at the Scene

The Salinas Valley is relatively flat, so when we arrived near Zabala Road, we were able to visually scan the area. Sure enough, we saw a man hanging from a transformer pole at the secondary level. He was supported by his safety strap and bent over backward. The superintendent and I sped off along a dirt road and, after arriving at the transformer pole, confirmed it was my friend David White hanging from the pole. We then contacted the utility company’s dispatcher to request emergency services at the scene.

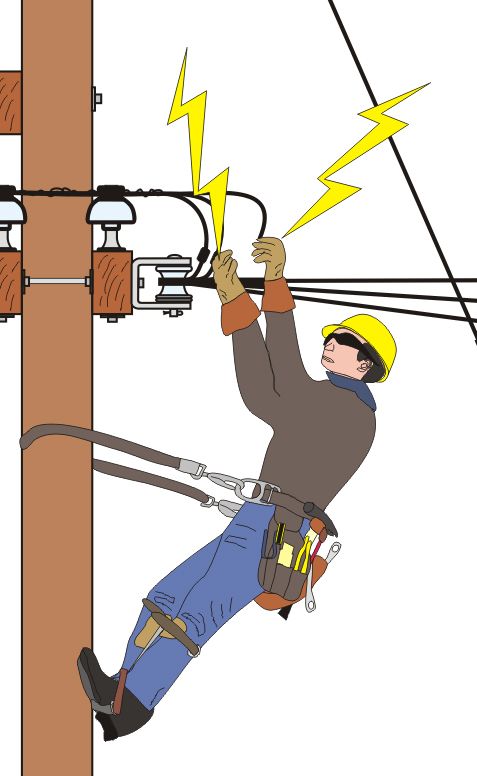

Next, I rapidly donned my tools, grabbed the handline I’d brought with me, climbed up to where David was hanging and positioned myself underneath him. While I was rigging up to lower him, it became obvious to me that he was no longer alive. The superintendent and I attempted artificial respiration after we got David to the ground, but it was hopeless. When emergency services arrived, they confirmed he had been dead for about one hour. Upon removal of David’s badly burned leather gloves, I saw that his hands had sustained severe burns as well. Emergency services loaded David’s body into the ambulance and headed back to town. Meanwhile, the superintendent and I attempted to figure out the details of what had happened to my friend.

Investigating the Accident

We first noticed that one fuse was blown on the primary side of a wye/delta three-phase connection that supplied three-wire 480-volt service to the irrigation pump. The superintendent and I also observed that the meter protector was burnt and damaged. It was clear that David had been attempting to figure out whether the blown fuse was caused by a defective transformer or a problem within the service riser or metering equipment.

From what we were able to determine, David had taken the following steps to identify the source of the problem:

- Inspected the transformer bank, service and meter.

- Opened the customer’s main switch, isolating the wiring and pump motor.

- Replaced the blown fuse to see if the bank was OK; the fuse then blew again.

- Opened the secondary jumpers to isolate the service and meter.

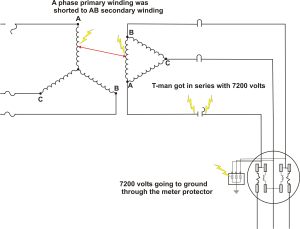

After David completed those steps, we believe he must have planned to re-fuse and then check to see if the bank was OK. This was the step during which his electrical contact occurred. For unknown reasons, he failed to open the other fuses. So, when David opened the first jumper, he placed himself in series with a flow of 7200 volts due to a short between the primary and secondary windings of one of the transformers.

A line crew that was dispatched to the scene replaced all three transformers. Each of the old transformers was thoroughly tested in the transformer shop, where it was confirmed that the winding insulation in one of the transformers had deteriorated, creating a dead short between the primary and secondary windings. The power flow diagram below shows the source and flow of the power that caused the accident.

Preventing a Recurrence

David could have prevented his electrical contact in these circumstances if he had opened all the primary fuses before he isolated the service and meter. Additionally, wearing rubber gloves would have insulated his hands from the flow of power.

This tragedy underscores the potential perils of solo work and the importance of being exceptionally careful and observant when working alone. Had David been a part of a line crew that responded to the trouble, it is likely another crew member would have reminded him to open the other fuses before isolating the service.

Prior to the accident, the utility company’s safety rule book already required employees to wear rubber gloves when working on energized 480-volt secondaries. After David passed away, the company added a rule requiring lineworkers to wear rubber gloves when working on the secondary side of any transformer suspected to be faulty. This accident is a prime example of how and why many safety rules and procedures have been established over the years.

The Aftermath

For me, the last part of this story is also the worst part.

The superintendent and I returned to the yard after we’d finished our preliminary investigation at the accident site. As you might imagine, the employees in the yard were in a state of concern and confusion as to what had happened. Once we confirmed that David was gone, the group consensus was that I should be the one to inform his father. I agreed and drove to the main office to speak with him, attempting to explain what had happened as best I could. When David’s father regained some of his composure, he said, “Alan, you have to be the one to inform his wife.” Once again, I reluctantly agreed and headed toward the hospital where Jane worked. We sat in a private room while I gradually explained what had happened to David. Not surprisingly, it was a highly emotional discussion.

Even now, decades later, it is difficult for me to describe how I felt that night once I made it home. I considered the upcoming funeral and how that would be. David’s accident left an indelible impression on me, further elevating my commitment to practice and promote safety at every opportunity.

Conclusion

This story is just one example of what can – and does – happen in our line of work. Transformers are some of the most common pieces of equipment lineworkers install and maintain. Their compact design places the high- and low-voltage windings close together, an arrangement that can result in a short circuit – the same as what occurred in David’s accident. Transformers are also susceptible to the buildup of internal pressure, which can result in hazardous explosions. The bottom line here is that lineworkers must be properly trained for the tasks they’re expected to perform; they must acquire the expertise to select appropriate transformers and transformer fuses, make the correct connections and safely investigate trouble situations.

About the Author: Alan Drew began his power industry career in 1959. While working for a local utility company, he earned a bachelor’s degree in electrical engineering. Drew was hired as the general superintendent for Clallam County Public Utility District in 1991. He moved to Boise, Idaho, in 1998, where he became an instructor with Northwest Lineman College and advanced to the position of senior vice president of research and development. He is a lifetime member of IEEE and a 2008 International Lineman Museum Hall of Fame inductee. Drew’s most recent accomplishment is writing “The American Lineman,” a book that honors the evolution and importance of the U.S. lineman. He retired in 2020 and is now a part-time technical consultant for Northwest Lineman College.