Determining Reasonable Energy Estimates

During a recent audit at a utility, it was discovered that the method used to determine incident heat energy was not appropriate for the utility’s application. Discussions with other utilities and subject matter experts indicate that the methods to determine the amount of exposure are challenging. It is unknown whether these are localized findings or a wider challenge in the utility industry. This article explores this topic, providing information on the most appropriate methods and highlighting how easily errors can occur.

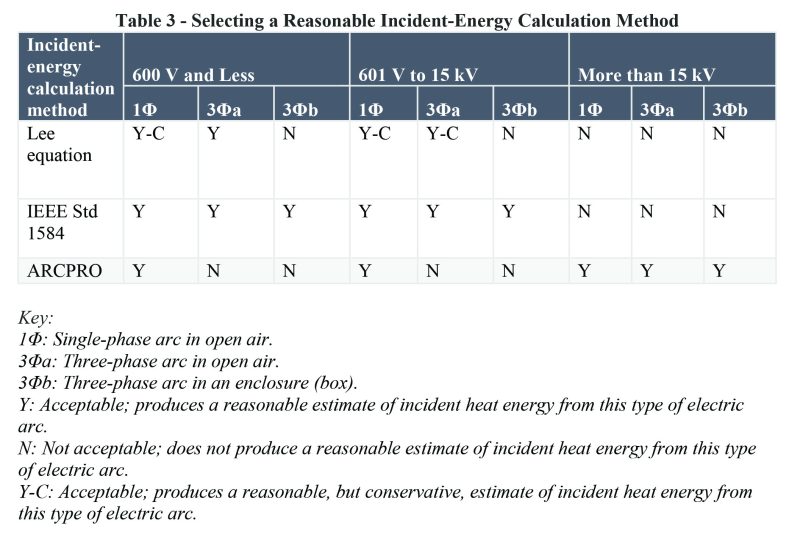

OSHA 29 CFR 1910.269(l)(8)(ii) requires that “the employer shall make a reasonable estimate of the incident heat energy to which the employee would be exposed.” This estimate identifies whether arc flash protection is required and, if so, what level of arc-rated PPE is required. OSHA does not require the calculation at each point of work but rather that, per Note 2 to 1910.269(l)(8)(ii), “the estimates represent the maximum employee exposure for those areas.” OSHA directs the employer to Appendix E for guidance on which methods shall be used for the various types of equipment and voltage levels (see Table 3 of Appendix E, below).

Arc-rated PPE was developed, tested and made available before a standard was published to calculate incident heat energy. At that time, it was known that incident heat energy varied between equipment, voltages and supply configurations. Ralph Lee published a peer-reviewed journal paper in 1982 that estimated incident heat energy using a theoretical radiative heat model. The model was similar to the heat transfer from a lamp or the sun shining on a surface, and it used maximum electrical power transfers as well as other theoretical assumptions. This was the initial guidance that spurred rapid lab testing. However, all lab equipment and testing were focused on the lower voltages (<600 volts). This led to the development of the first standard used to calculate arc flash incident energy: IEEE 1584-2002, “IEEE Guide for Performing Arc Flash Hazard Calculations.” A few shortcomings of IEEE 1584-2002 soon became apparent. The model provided empirical testing – and hence equations – that were limited to:

- Three-phase systems.

- Testing performed on low-voltage equipment (<600 volts).

- *Box-type (metal-enclosed or metal-clad) equipment.

*It is important to note that Lee’s theoretical model was used to estimate medium- and high-voltage open-air three-phase arc plasma models for utilities.

Closing the Gaps

Overhead power lines, equipment bushings and open-air switches have greater spacing between bus conductors compared to metal-clad/box-type equipment. Due to the transmission and distribution minimum approach distance and transient overvoltage considerations, greater working distances are required. Also, T&D arcs occur mainly between phase to ground, although three-phase arcs are possible and may require determination. OSHA recommends the single-phase-to-ground estimate. Using box-type three-phase equations for single-phase-to-ground calculations will result in inaccurate results. These are some of the gaps between the IEEE 1584-2002 model and what utilities require for open-air arcs.

Software running on an MS-DOS platform was available to plug these gaps but required updates and improvements to the model. After the publication of IEEE 1584-2002, Pacific Gas & Electric, EPRI and Kinectrics collaborated to ramp up empirical testing under Marcia Eblen (now retired from PG&E) and Tom Short (EPRI) in an attempt to address open-air arcs. Kinectrics improved the software and launched ArcPro v2.0. EPRI went on to create their own set of equations. These efforts remain the cornerstone for assessing incident heat energy in utility open-air arcs and led to the tables now found in the National Electrical Safety Code and Appendix E to OSHA 1910.269.

The ArcPro software continues to evolve and can adapt to new findings faster than the NESC or OSHA. Lee’s three-phase theoretical model was used for >1 kV in IEEE 1584-2002 and remains the de facto method in the IEEE 1584-2018 update. Today, other commercial software packages – like SKM PowerTools, EasyPower and ETAP – have incorporated IEEE 1584 methods, NESC tables and EPRI methods.

The majority of commercial industry use these software packages to model their low-voltage metal-clad equipment (e.g., disconnects, panelboards, control panels, motor control centers, switchgear, switchboards) with a great measure of accuracy.

When the model is used on medium-voltage open-air arcs, IEEE 1584-2018 defaults to a three-phase arc using the Lee model, thus producing inaccurate incident heat energy results. For medium-voltage metal-clad equipment, including a 2.5x-3x multiplier on the low-voltage equations in a horizontal conductor in a box fixes this problem, but this fix is usually performed by hand.

To create awareness and address the problem being observed by the authors during site visits, a model on a 13.8-kV power line was created using a commercial software package incorporating the IEEE 1584 method. Although overhead open-air (transmission and distribution) arcs are inherently single phase to ground, the IEEE 1584 model uses a three-phase calculation from the Lee method, producing an incident heat energy >40 cal/cm2. The NESC, EPRI, OSHA and ArcPro models correctly use a single-phase model and provide more realistic values (compared to actual testing) that require daily arc-rated workwear, minimum 8-cal/cm2 PPE. These results should come as no surprise. To prevent these errors, Table 3 in Appendix E to OSHA 1910.269 indicates which method should be used for which situation.

Overcoming the Challenge

The challenge facing utilities and some larger commercial industrial clients is that it makes sense to model the entire network using a single software package. Inexperienced or uninformed engineers may fall into the trap of assuming that the software “does it all.” This is very different from the idea that erroneous data in equals erroneous data out. In these instances, we are observing correct data input into the software but incorrect results being generated by end users unaware of the issue. How can this challenge best be overcome?

Utilities should delineate the modeling of their networks to separate transmission and distribution from lower-voltage models. Model metal-clad medium-voltage equipment 15 kV and below with SKM PowerTools, EasyPower or ETAP. For open-air arcs, use the network load-flow software (e.g., CYME, EMTP, PSLF) to determine the fault current for various system voltages. Then, provide the specific working distances based on the minimum approach distances and transient overvoltage calculations. Finally, determine the trip times or worst-case times. When these parameters are available, use the batch data processing function on the latest version of the ArcPro software to model the single-phase arc. The analysis of these results in the context of the network provides the reasonable estimate of incident heat energy required by OSHA. Finally, utilities should use engineering firms that have experience modeling overhead lines and a thorough knowledge of NESC and OSHA tables.

About the Authors: Danny Raines, CUSP, is an author, an OSHA-authorized trainer, and a transmission and distribution safety consultant who retired from Georgia Power after 40 years of service and now operates Raines Utility Safety Solutions LLC.

Zarheer Jooma is a professional engineer and partner at e-Hazard (https://e-hazard.com). He earned a master’s degree in electrical engineering, is a senior member of IEEE, has convened and chaired arc flash safety standards, and is a member of both ASTM F18 and IEC TC-78. Jooma performs electrical network design, arc flash studies, electrical safety training, incident investigations and auditing. He is also the technical paper review chair for two IEEE journals and the incoming chair for the IEEE Electrical Safety Workshop 2025.