A Second Look at Safety Glasses

Safety glasses weren’t always considered part of everyday utility construction equipment. It was during the mid-1980s when companies really started embracing the use of safety glasses as mandatory personal protective equipment (PPE). Today you cannot step foot on a utility construction site without proper PPE, including safety glasses. Much has been accomplished in eyewear design, fit and comfort over the past 25 years, and many eye injuries have been avoided as a result of these significant changes. The purpose of this Tailgate is to cover some of the basics of safety glasses, as well as address some of the concerns about wearing them.

The Basics

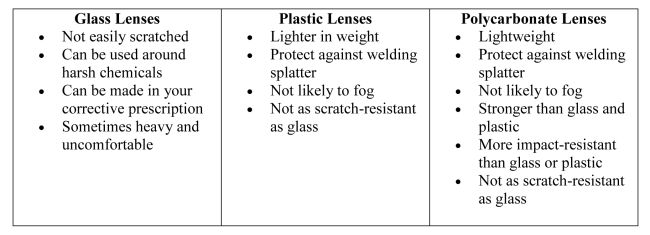

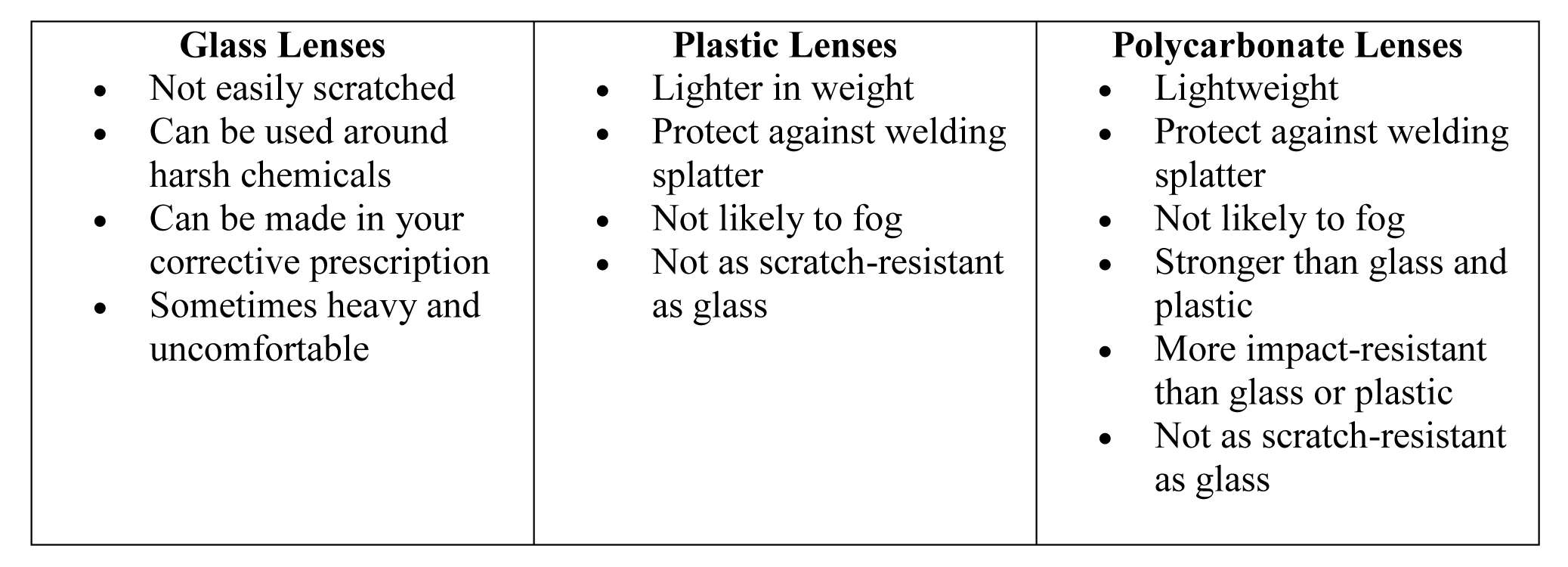

Safety glasses are made with shatter-resistant lenses to protect the eye from flying debris. Although safety lenses may be constructed from a number of materials with various impact resistances, testing standards require that they maintain a minimum thickness at the thinnest point, regardless of material. The following table contrasts the benefits of each lens type typically available in approved safety eyewear.

Approved industrial eye protection meets the performance standards of ANSI Z87.1. Safety glasses that meet this standard must pass a high-velocity object test for frames and lenses, and meet the criteria for lens thickness, corrosion, flammability and side-shield protection, as well as optical requirements. Glasses that meet the ANSI Z87.1 standard are marked with Z87 on the inside of the frame temple bars.

Issues and Concerns

Although much has been done to ingrain safety glass use into everyday life, many eye injuries still occur on a daily basis. According to the Centers for Disease Control and Prevention, more than 2,000 workplace eye injuries occur every day, with 100 of them resulting in one or more days of lost work. A U.S. Bureau of Labor Statistics survey of workers who suffered eye injuries found that nearly three out of five were not wearing eye protection at the time of the accident. The most common answer given by construction workers with eye injuries when asked why they weren’t wearing safety glasses? “I didn’t think that I needed them!”

Beyond the pain and suffering incurred by the injured employee, additional consequences exist for every eye injury that occurs. The cost of eye injuries to employers is more than $300 million in lost production time, medical expenses and workers’ compensation. The rates of eye injury and lost work time can each be reduced by 50 percent or more when personal protective eyewear is worn, according to a review of the effectiveness of various interventions for preventing work-related eye injuries.

Improving Our Odds

Much research has been done over the years to understand why employees choose not to wear safety glasses. The following suggestions are based on this research with the intent to help drive improvements that would increase usage of safety glasses.

Comfort/Fit: Glasses that are comfortable and fit the wearer are shown to be used more often than those that do not.

Eye Injury Education: Helping employees understand the consequences of eye injuries motivates them to protect their eyes.

Style/Choice: Having a preferred style or allowing employees to make a choice will increase safety glass use.

Enforcement/Reinforcement: Ensuring glasses are worn and providing coaching will help the employee understand the need for eye protection.

Accessibility/Availability: Having an easily accessible supply of safety glasses increases employee usage.

Anti-fogging: Glasses that fog in higher temperatures or during labor-intensive work decrease the employee’s use of eyewear. Anti-fog glasses and anti-fog solutions/wipes have been shown to significantly improve performance, resulting in increased eye protection use.

Although we have seen dramatic improvement in eye protection development and use over the past three decades, an opportunity exists for all of us to do our part and help those we work with protect their eyes. By using the suggestions in this Tailgate, you can have a positive and significant impact on your co-workers and their families.

About the Author: John Boyle is vice president of safety and quality for INTREN, an electric, gas and telecommunication construction company based in Union, Ill. Boyle has more than 27 years of experience, and has worked in nuclear and wind power generation and electric and gas distribution.