FR Layering Techniques

With new revisions to the National Electrical Safety Code (NESC), many electric utilities and contractors are discovering that a standard HRC 2 program is no longer adequate. Numerous companies are now turning to layering of flame-resistant (FR) garments to achieve the required levels of protection. Well-designed, well-managed layering programs will increase worker safety and comfort. This article will discuss why layering is important and how to ensure that your layering program works.

What Does NESC 2012 Require?

Although the NESC is rather brief in its discussion of FR clothing, Section 410 does describe practical and reasonable steps that utility companies should follow to safeguard workers covered by this code. While reading the code is essential to full understanding and proper implementation, here are some basic points in plain English.

FR Clothing Rules for Employers

• Inform employees of the safety rules.

• Provide all appropriate training and verify proficiency.

• Perform an assessment to determine if there is potential for employee exposure to an electric arc.

o If the potential exposure is 2 cal/cm2 or less, wearing nonmelting, 100 percent cotton clothing instead of arc-rated clothing is permitted.

o If the potential exposure is greater than 2 cal/cm2, the employer must perform a detailed arc hazard assessment or use the tables in 410 to determine the minimum arc rating that FR clothing should provide.

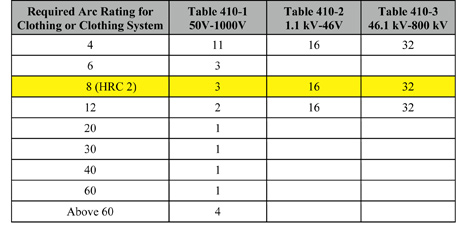

Although many utilities have performed detailed hazard assessments to determine the various arc flash protection levels that are required for their system, there are also many that have not. The three tables in 410 provide compelling evidence that the basic HRC 2 programs that are commonly used today may be out of step with the reality of hazards. Here is a breakdown of the number of times that various arc ratings are mentioned in the tables.

The purpose for showing the data in this way is not to advocate for any particular solution. The tables do not claim to be the only valid source for data and each utility will implement their particular FR clothing program based on their hazards and other unique considerations. However, what is obvious is that having a program that only requires employees to wear HRC 2 garments can lead to two significant problems:

• There are many tasks where employees are not protected enough. The tables in 410 list 58 different conditions that require protection at 12 calories or above.

• There are many tasks where employees are overprotected. Heat stress is a major concern for most electric utilities and the tables in 410 list 59 different conditions that only require 4 cal/cm2.

This is not to say that HRC 2 systems aren’t correct for many applications. In fact, the tables list 113 different conditions in which wearing an HRC 2 program would provide the required protection. However, the challenge today is to provide the proper level of protection in every instance while not increasing other hazards such as heat stress. Layering is the solution.

Implementing an FR Layering Program

Once the need for layering becomes clear, the next question is how to do it. This is where safety professionals can really make a difference. The process of planning, communicating and managing an FR layering program doesn’t happen without safety professionals who are willing to devote resources to the project. Following is a three-step process to properly implement a layering program at your facility.

Step 1: Document Your Hazards and Organize the Data

• Perform a detailed hazard analysis or use the tables, if appropriate, in order to better understand your particular protection requirements.

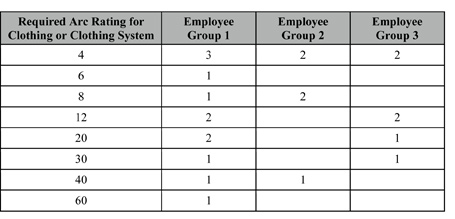

• Organize your employees into groups that make sense – such as distribution lineworkers, meter service, power plant electricians and power plant operators – and try to understand how often they would have to change clothes given the various jobs they have to perform. Here is a simple example of what the data might look like.

• Document the various fabrics that exist in your system and request that your FR clothing provider send any system arc ratings available for these fabrics. Analyze the data to determine which fabric combinations will have the best system arc ratings for your system.

Note: Many garment manufacturers and fabric mills will have layering data and most will freely share it. Due to important arc testing changes that occurred in 2007, you may need to request the actual reports to verify the data is valid. ArcWear.com, an independent testing company, is also a good source for layering data. Visit www.arcwear.com/arctest/arctest.php for more information.

• If your system has a tremendous number of choices, your possible combinations can get out of control. You’ll need to look for ways to reduce that complexity so that training and communication will be manageable. Here are a few good tips.

o Establish one knit fabric and one woven fabric as your preferred layering fabrics for shirts. Employees need to know they can wear a shirt to work that can layer with other garments to cover various requirements that come up during the day. Without this base, they could show up to work and not be able to layer up to get the protection they need for a particular task.

o Identify garments that cannot be layered. Lack of data or bad data can eliminate some garments from your layering program. Identify them and make sure they are only used in areas that do not require layering. Most companies that use layering will phase out these products.

o Don’t forget to document layering for trousers and jeans. Most FR layering programs focus on shirts. If you are going to provide the same high arc protection for the lower torso, you may need to use arc-rated over-pants.

o Use arc flash suits for 40 cal and above. It’s very difficult to find practical layering options that will get your workers to 40 calories. Nothing beats arc flash suits for the larger arcs. They are practical and easy to remove if an arc happens. Although the NESC does not define what an arc flash suit is, there are many vendors of arc flash suits that can provide complete kits to take care of these hazards.

Step 2: Communicate Your Layering Rules

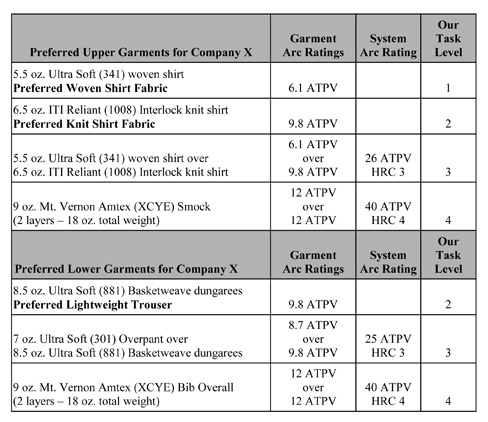

Most utilities that use layering will organize their system into various levels, and they’ll provide a chart to show their employees which garments will layer up to meet the various levels. The employees will use this chart to quickly determine which garments will provide the proper protection level for their assigned tasks.

Here is a shortened example of how the layering data might be communicated. While some companies group tasks into levels that are identical to those defined in NFPA 70E, many do not.

Step 3: Manage the System Over Time

One of the big challenges of a layering system is how to respond to changes in the market. New fabrics are introduced all the time and allowing them into a well-designed layering system can cause confusion that leads to improper layering. The key to managing this is to be diligent in requiring that new fabrics come with all the layering data you need and that the layering results are still sufficient for the hazards.

FR safety garments have come a long way in both comfort and style. With a well-designed layering program, you have the opportunity to achieve the superior comfort that your employees want while complying with the new requirements for extra protection.

About the Author: Will Vereen is the corporate vice president for Riverside Manufacturing Company. He is also in charge of technical research and development for Riverside’s Protective Apparel division, oversees all FR product development and currently has three FR garment patents. Vereen is an active member of the ASTM F18 and F23 committees and has participated in the subcommittees that authored ASTM F1506, F2757 and F1449. He has a management degree from Georgia Institute of Technology and more than 20 years of experience with textile, apparel and uniform companies. For more information, including Riverside’s layering data, visit www.riversidefr.com.

Editor’s Note: The topic of PPE is controversial in the utility industry, particularly regarding FR clothing. Incident Prevention does not assume a position on this subject. We serve as a platform to voice different perspectives and enlighten our readers with varying opinions. If you have a different view and wish to weigh in, please post your comments below.