Variabilities in Electrical Arc Flash Protection

Rather than overcomplicating PPE decisions, invest time in safety through design to minimize the likelihood of an arc event.

Accuracies are synonymous with safety and science. While many perceive that electrical safety needs to be highly exact, this article aims at creating awareness of why sticking to the basics is effective.

But before we delve into variability in electrical engineering, safe electrical work practices and electrical PPE, here is a brief story my second-year engineering physics professor shared when I was in school: A person stands in the center of a boxing ring; their soulmate stands in the corner. The person in the center is only allowed to walk toward their soulmate in discrete steps defined by exactly halving the distance between the two. The physicists witnessing this agree that it will be impossible for the distance between the two to ever reach zero. The engineers understand that they can eventually get as close to their soulmate as needed for a happily ever after.

Electrical Engineering

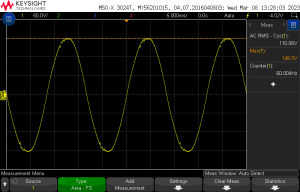

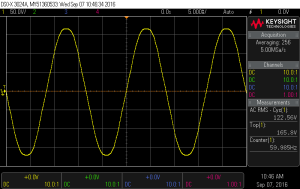

A post on Stack Exchange (https://electronics.stackexchange.com/questions/256283/what-does-the-us-power-supply-waveform-look-like) shows that 120 volts can actually be a 110-volt sine wave with a peak of 149 volts (see Picture 1), and even this varies between the home and the workplace (see Picture 2). The 110-volt equivalent (DC) – or root mean square – presents a 149-volt peak while a 122-volt equivalent presents a 165-volt peak (i.e., the measured empirical data differs from the theoretical conversion from root mean square to peak).

Voltages fluctuate in our homes, workplaces, large industrial plants and the power grid. These fluctuations may occur due to large motors, planned and unplanned outages, and time of day. Like voltages, currents also fluctuate. As little as a 1-amp current fluctuation can be the difference between a breaker tripping in 0.4 milliseconds or 0.4 seconds or even 4 seconds.

Current that flows during an electrical fault is known as short-circuit or fault current. Fault current is greatly influenced by the fault type. Leaving grounds on a circuit will generate close to the maximum short-circuit current that the system can deliver; this is called a bolted fault. If a worker accidentally slips a tool between conductors, an arc flash may occur. Arc flash is the plasma created between the conductors due to the breakdown of air. The arcing fault has more impedance than the scenario with the bolted fault containing the grounds and may propagate. Each of these scenarios influences the magnitude of the (arcing) fault current and the protective device operating time. Higher impedances produce lower short-circuit current, resulting in a longer trip time. So, it is impossible to predict the actual, real-life arc flash energy.

To cater to all these variabilities in fault current and protective device operating times, both the maximum and minimum fault currents and the associated protective device tripping times are considered. The fault currents and associated trip times are two key inputs used to estimate the arc flash hazard/incident energy (or arc flash energy). Some software can determine a wide range of combinations of these parameters and select a worst-case value. However, while science tries to model the incident energy as close to reality as possible, there are too many variables to call arc flash energy calculations “exact.” The IEEE 1584-2018 model used laboratory tests to create a statistically representative set of equations. The probability is extremely high that the real energy will be lower than the calculated energy, while the probability of predicting the actual energy is extremely low. This is exactly what any scientific committee would aim to achieve in a safety standard.

Forensic investigations and a literature review indicate that real-life accidents have produced lower energy levels than were predicted by the IEEE 1584-2018 calculations. Experience in the field shows that (1) the calculated incident energy is the worst case and (2) end users have no reason to believe that the true arc flash energy will exceed calculated values.

Variabilities in Work Practices

The distance from the arc source to the worker is highly variable. In practice, tasks such as removing a cover for thermal imaging and troubleshooting place the worker farther away than the 18-inch working distance for low voltage (208 volts to 480 volts) that is recommended in IEEE 1584-2018. During the development of the engineering equations, the working distance equivalency varied between 15 and 36 inches, helping to provide a worst case. Variability in the working distance is not only influenced by the position of the worker; research has demonstrated that in certain high-voltage applications, the arc has the potential to move, yielding a lower incident energy exposure to the worker than theoretically calculated (see https://ieeexplore.ieee.org/document/7439799). Here is a final note on working distance: The optimal worker position is to stand to the side of equipment, outside the line of fire and away from potential projectiles when possible (see https://ieeexplore.ieee.org/document/9188321).

Variability also occurs with PPE garments, specifically the materials used and how the gear is worn. Most workers prefer loose-fitting garments to allow for dexterity. This is quite different from how fabric is tested; when rated, it is firmly placed on the test panel. Secondly, although standards do not allow non-arc-rated layers to count toward the total protection level, most natural fibers will add a margin of protection. Arc-rated inner layers, when tested in combination, can potentially offer great gains in protection. It is extremely important to note that both OSHA and voluntary consensus standards prohibit the use of low-melting synthetic fabrics. The fit of the fabrics (tight vs. loose) can offer marginal protection that cannot be quantified. So, looseness and layering – including the type of layering – is another area in which variability works in favor of employee protection.

Fabrics, Test Methods and Assembled Garments

The arc ratings provided on garment labels are calculated using either ASTM F1959 or IEC 61482-1-1 A. The test to calculate an arc rating is not performed on a finished garment; it is done on the raw fabric material or material system used to construct the garment. Clothing design often results in significant portions of garments possessing multiple protective layers. Pockets, plackets, storm flaps, overlaps and similar items create these multilayer (i.e., more protective) areas.

In recent months, end users have had concerns about information stemming from retesting of various competitive products purchased from major reputable manufacturers. In nearly every case, retesting resulted in arc ratings lower than those listed on product labels. ASTM F1506 does not require retesting; however, when it is conducted, variations in arc ratings are not surprising or concerning to a trained eye. Numerous factors can create arc rating variability, such as natural variability in textile manufacturing, weight, finishing procedure and fabric color. Although there is no hard and fast rule, the general trend is that darker colors tend to produce slightly higher arc ratings than the same fabric in lighter colors. These differences may result in minor rating variations, but they very likely do not impact practical protection levels. In fact, even when many of these variables are removed, there can still be wide variations in results. One study that included 26 different arc ratings of the same fabric over several years found results to range from 8.3 to 13 cal/cm2. Each of the 26 arc ratings is a valid rating and could potentially be used to label the product.

Finally, consider the conservative nature of arc ratings. A rating is generated from a fabric tightly held against a sensor assembly. In contrast, a properly fitting garment incorporates a certain amount of ease, adding an insulating air layer between the garment and the skin, as mentioned earlier.

Concluding Remarks

Research and incident investigations show that workers are protected when arc flash incident energy calculations are correctly performed, arc-rated PPE is procured through reputable suppliers and end users dress to the correct levels. There is no literature indicating that any of the following activities will benefit worker safety or expose the employer to undue risk: padding the calculated numbers; being concerned with the intricacies of fabrics and batches; and repeatedly testing and retesting garments.

Employers that use and comply with OSHA and ASTM standards and NFPA 70E help to create a safe working environment. Employees who adhere to the safety rules do the same. Rather than overcomplicating arc-rated PPE decisions, our time is better invested in safety through design to minimize the likelihood of an arc event. All risk-based decisions should be driven by an understanding that variability is embedded in every aspect of electrical arc flash protection.

About the Authors: Zarheer Jooma, P.E., is a partner at e-Hazard (https://e-hazard.com). He has convened and chaired arc flash safety standards and is a member of both ASTM F18 and IEC TC 78. Jooma performs electrical network design, arc flash studies, electrical safety training, incident investigations and auditing. He is the technical paper review chair for two IEEE journals and chair for the IEEE Electrical Safety Workshop 2025.

Brian Shiels is the service line manager for the ArcWear (https://arcwear.com) division of Kinectrics and a leading expert in the testing and development of arc-rated clothing. His professional experience includes quality management as well as the development and testing of thermal protective clothing and equipment. Among other responsibilities, Shiels is a longstanding member of a variety of standards development organizations, including ASTM, NFPA, AATCC and ISO. He earned his master’s degree in textile chemistry from North Carolina State University, with a special focus on protective clothing.

Stacy Klausing, M.S., is a senior project manager at ArcWear. Her professional experience includes project management in testing laboratories, testing and evaluating fabric related to PPE, and execution and management of an ISO 17025-accredited quality system. She earned her master’s degree from the University of Kentucky and is a Six Sigma Green Belt from North Carolina State University.