Safety and Human Performance: You Can’t Have One Without the Other

Safety and human performance professionals have spent a lot of time trying to find that one nugget, that one silver bullet, that one thing that – if we used it – would stop people from getting hurt. I’ve always been a firm believer that safety and productivity can coexist at the same time. The gap between the two is a lack of focus on behavior.

Companies hire people, show them how to use personal protective equipment and then teach them how to perform the tasks they were hired to do. They typically do not train employees on ideal work behaviors, those attitudes they want workers to have while on the job performing tasks. In this absence, people create their own behavioral patterns.

Enhanced Human Performance

Human performance is at the forefront of Entergy’s utility business. Outside agencies have begun asking what we are going to do about grid reliability and stability, and the effects of human error. The suggestion was human error reduction tools; our response has been enhanced human performance (EHU).

EHU began as a quest to reduce human errors by 20 percent. When we began peeling the proverbial onion, we quickly noticed that human errors were happening throughout Entergy. Ask yourself this question: “What was the root cause of the last three major injuries in my company?” We consistently found that human error has contributed to more than 95 percent of our injuries.

Developed internally, EHU was derived from conventional human performance programs that have been around for years in the nuclear power generation industry. The more traditional version of human performance is focused on protecting the plant from the people operating it. The enhanced version is more focused on safety and how people’s behaviors can affect their lives. The first topic we address with our workers is what’s in it for them. We want our employees and contractors to take the behaviors home and use them with their families. This helps our team to internalize the culture.

Training

When training, we spend the majority of the day teaching our employees 10 behavioral tools that help people focus on what they’re doing. After the instructional portion, we move into a dynamic learning environment where the student teaches their classmates the way each tool is designed to be used. The student trainers use a variety of approaches to teach the preferred method of using each tool. We’ve been amazed by how creative the class participants have been in their delivery methods. From rapping to acting out skits, students are teaching and learning proper methods.

EHU consists of several approaches for error minimization. We look at the ability to reduce active errors while finding and destroying latent conditions that lead to errors. To further break down this concept, following is a description of the differences.

What is an Error?

An error occurs when a person fails to exhibit the desired behavioral patterns established through EHU training and there is a consequence. There must be a consequence or the incorrect behavior is simply a precursor. If you see a person swinging a door open very quickly, but it does not hit anyone, it could be considered a precursor. If the door hits a person and injures them, it is an error. The most important part of this is the behavior. This is why Entergy is stressing the need to look for unwanted behaviors, not just wait for consequences.

Active errors are caused by people making mistakes. It’s important to understand that this will never fully go away. People make mistakes and no one is perfect or above reproach. Active errors are visible when something of value is damaged or lost. The person choosing to swing the door open too quickly is demonstrating unwanted behavior. If the person injures another person, it is an active error. The person with the incorrect behavior is choosing to not correct the unwanted action.

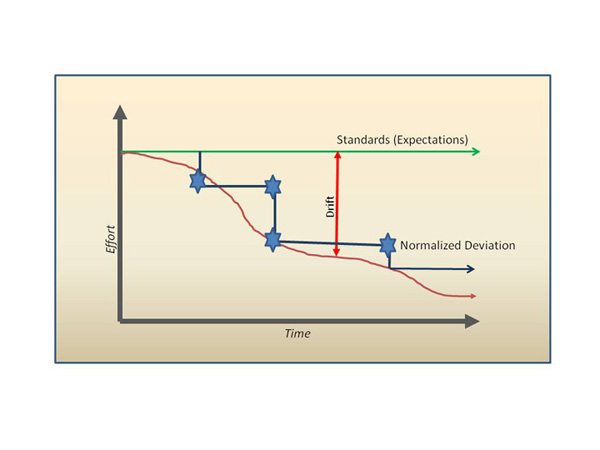

Latent conditions that lead to errors are a little tougher to spot. These conditions exist in our values, procedures, processes, equipment and programs. One particularly tough latent condition is a term we call “drift.” The classic name for drift is normalized deviation. When a person is allowed to drift away from a standard and it goes unchecked, the person sometimes does not even realize it has happened. The graph below shows how this looks:

Latent conditions become a weakness in the defenses of your organization, thus setting up workers to not be successful. It has been said that almost 95 percent of all errors are directly attributed to these latent conditions.

Enhanced Human Performance Tools

Our company has elected to design and teach 10 human performance tools. These tools have been around for a while, but have not been delivered to personnel in a way that has made it fundamentally easy to use them. Along with training, we have created job aids and are sending out weekly and monthly reminders to be used in tailboard meetings. We have even begun using a daily trivia challenge to encourage our employees to learn the terminology and demonstrate the use of EHU techniques.

The 10 EHU tools that we are training on are self-checking, questioning attitude, procedure usage, place-keeping, prejob brief, post-job review, turnover, coaching, effective communications and peer checking. These tools have very specific uses and people must be continuously trained on them. Our employees are encouraged to use the tools at home in order to internalize their importance and develop the habit of using them.

A sample of one of the tools that we are teaching is self-checking. This tool uses the acronym S.T.A.R., which stands for Stop, Think, Act and Review. It is a simple process that teaches a person to gain complete focus prior to taking any action. We have realized that if we do this every time we are about to perform a task, our chances for success are extremely improved. Mistakes occur when a person is subjected to and influenced by traps. To eliminate the trap, or error-likely situation, the person has to be fully engaged and sure about what they are doing.

Enhanced Human Performance Traps

The EHU traps are 10 pre-identified conditions that can cause a person to err. These traps are common to workers and happen whether we want them to or not. Our best defenses for these traps are the EHU tools. The list of traps is comprised of time pressure, mental stress, change/abnormal, first shift/late shift, multiple tasks, vague guidance, peer pressure, overconfidence, distractions and physical environment. We train our employees to recognize these traps and avoid them or get themselves out of the trap once they have identified it. At one time or another, every one of us has experienced these traps. It is crucial to be aware they exist, be able to identify when you are in one and know how to get out of it.

Changing Culture, Changing Lives

One key takeaway that we have learned is that EHU is not a program to be trained, but a culture shift. The culture of using EHU to perform tasks has to be cultivated. We are using training and job aids to assist Entergy employees in learning the techniques, but we have to follow up with observations and encouragement if we want to impact the culture. We’ve developed a process to help make the training stick that provides structured coaching and observation methods to watch employees demonstrate the use of the techniques they’ve been taught. Additionally, we’ve added goals and objectives that help change and sustain our culture. We are seeing peers coach each other on what they learned in class and how it should translate to their work environment.

The culture change will impact our company’s bottom line, our safety record and our productivity, but those are not the most important issues. What’s more important is watching our workforce learn better ways to protect themselves and ultimately improve their quality of life both on the job and at home. Teaching the next generation how to use these EHU techniques will only lead to a better workforce tomorrow.

Entergy believes that lowering the severity and reducing the frequency of human error will greatly improve our safety and reliability. We are just getting started, but we’ve already seen our employees embrace the concepts and practice the techniques.

About the Author: David W. Bowman is manager of program and curriculum development for Entergy Utility Operations and Energy Delivery. Throughout his 11-year career with Entergy, he has worked in commercial nuclear power generation, fossil fuel generation and transmission. Bowman moved into safety and human performance in 2004 and was promoted to manager of utility operations program and curriculum development in 2010, when he began developing and teaching enhanced human performance. Bowman was recently asked to speak at the inaugural North American Electric Reliability Corporation human performance conference, where he delivered a presentation titled “EHU for Contractors.”