Rubber Insulating Sleeves and Arc Flash Protection

Rubber insulating sleeves are commonly worn with dielectric gloves in high-voltage applications to provide added insulation from electrical contact for those working on energized equipment. The rubber insulating gloves and rubber insulating sleeves are worn for shock protection; sleeves typically are worn with rubber insulating gloves when the arm can cross the minimum approach distance or the restricted approach boundary. A protector glove typically is used for arc flash protection and for mechanical protection of the rubber insulating glove, but this over-glove does not protect the entire glove and does not extend up a rubber insulating sleeve.

Many lineworkers wear short-sleeved, arc-rated (AR) T-shirts under rubber insulating sleeves, and a concern was raised in the industry that the insulating sleeves are not arc-rated. As a result, Iowa OSHA issued a letter of interpretation that since rubber sleeves are not arc-rated, long-sleeved AR shirts are required, in their opinion, to meet the letter of OSHA 29 CFR 1910.269. Federal OSHA has not issued an interpretation.

Since there is currently no standard that covers arc flash testing of rubber insulated products, ArcWear – an independent, third-party testing laboratory – studied several sleeves to assess arm protection and ignition withstand. That’s because although, per Iowa OSHA, workers are required to wear arc-rated, long-sleeved shirts under the rubber sleeve for arc flash protection, they may unnecessarily contribute to heat stress, and there was no evidence one way or another that this requirement would add to the end users’ protection levels. The configuration of wearing a short-sleeved T-shirt tucked into a rubber insulating glove may be more comfortable to a worker while providing complete coverage, but the question remained, would it provide enough protection in case of an arc flash?

At the request of three utilities, ArcWear performed the study to evaluate the ignition resistance of insulating rubber sleeves worn with rubber gloves, leather protectors and AR T-shirts. This study has been published and is cited below.

The Study

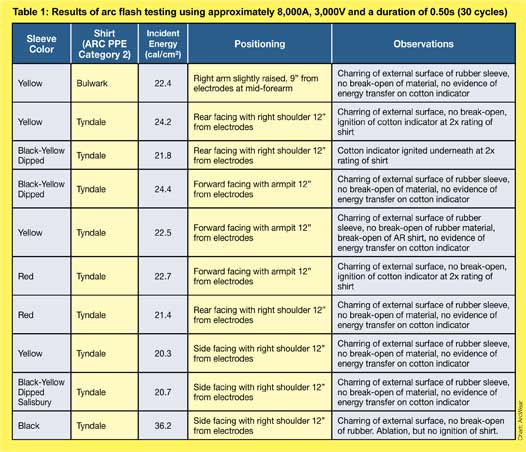

ArcWear evaluated the sleeves and AR T-shirts underneath the rubber insulating sleeves at Kinectrics High Current lab, the world’s leading arc-testing facility. Two types of molded sleeves in various colors were placed on a mannequin with cotton thermal indicators underneath and exposed to an arc flash in a laboratory setting using the setup of ASTM F2621 for finished products. This work was performed because the three utilities that requested the study desired to receive a letter of interpretation from OSHA or a standard from ASTM to allow sleeve use and discern the limitations of the sleeves for ignition. Testing was performed at various incident energy levels using a 12-inch open-air arc, 3,000 volts and a duration of ~0.5s. Various positions were used in testing to replicate work settings, with different angles of exposure to the rubber insulating sleeves to assure the testing was replicative of common position and exposure types in the field. Rubber insulating sleeves typically are worn over the long-sleeved shirt and secured with a harness for proper fit. For this research, a short-sleeved T-shirt – which would be more comfortable for a worker – was tucked into the rubber insulating sleeve and no harness was used to secure the product to the body, leaving an opening at the top of the arm as a worst-case scenario in testing. All tested products were Class 2 rubber sleeves compliant with ASTM D1051, and all arc-rated shirts used in testing were PPE Category 2 per NFPA 70E 2018. Table 1 below shows details of the evaluations performed.

None of the sleeves, in any of the colors tested, ignited in any of the exposures up to 40 cal/cm². Testing was performed at incident energy levels between 21 and 36 cal/cm², and the evidence indicated that the energy did not travel far enough down the sleeve to create burns on the cotton sleeve below the AR T-shirt sleeve – even if the sleeve holders were disconnected – if the T-shirt sleeves were at least 25 centimeters (10 inches) long.

Based on the results in testing, there was no evidence of thermal energy transfer beyond the short-sleeved AR shirt or through the rubber insulating sleeves tested (no scorching of the cotton indicator shirt used in ASTM F2621 for evaluation). There also was no evidence of the energy traveling into the arm area past the 10-inch short sleeves, as tested, when worn underneath the sleeve and with the sleeve worn open and unsecured without a harness. No ignition of the rubber insulating sleeves was observed at the incident energy levels used in testing. The minimum 10-inch sleeves also kept the arm covered in the configurations tested. In some configurations – specifically arms overhead – shorter sleeves allowed part of the indicator fabric to be exposed and were not tested to assure full coverage.

Standard and Testing Updates

We are sometimes asked to test rubber insulating gloves and sleeves for an arc rating, but as previously mentioned, a standard doesn’t currently exist to specifically cover these products. This may soon change, however, as a standard is in progress in ASTM F18 for sleeves, and a test method for D120 gloves appears to be close to passage. Currently, while they can be tested for heat transfer properties and provided with a rating result, the major concern with rubber insulating gloves and sleeves is the ignition point in an exposure. Through years of testing, we know that rubber insulating products will ignite at some energy level dependent upon the formulation and thickness of the product.

The standard underway through the ASTM F18 committee will address a procedure and outcome for the arc flash testing of rubber insulating sleeves. Testing will be performed using the general setup and parameters of ASTM F2621. The work item, in its first draft, proposes a minimum of eight samples from both the back and sides and will result, if approved in its current draft, in an arc rating limit and an ignition withstand for the product tested. The publication of this standard will allow end users to adequately match their product choices to the exposure level.

Utilities and others that encounter electrical hazards must perform an assessment to determine the hazards present in their workplace. OSHA 1910.269 requires use of PPE that matches the hazard. Stay tuned for word from ASTM F18 or OSHA on important updates.

Authors’ Note: The original and full test report referenced in this article is available for free courtesy of the utilities that paid for lab time and ArcWear, which consulted on the project. It can be accessed at www.arcwear.com/blog/short-sleeved-ar-rubber-insulating-sleeves-arcwear-study/.

About the Authors: Hugh Hoagland is the founder of e-Hazard (www.e-hazard.com) and an expert on electrical arc testing and safety. He has aided in the development of legislation and standards in the U.S. and globally.

Stacy Klausing, M.S., is the project manager at ArcWear (www.arcwear.com), which performs accredited testing for NFPA 2112 flash fire and ASTM F1506 arc flash.