Recent PPE Changes and 2015 Trends

2014 was a year of changes in electrical safety. The new OSHA 29 CFR 1910.269 standard has moved arc-rated (AR) clothing and PPE to the forefront, unlike the 1994 changes. Additionally, for facilities covered by NFPA 70E, the new 70E standard has added a level of complexity to PPE. This article will review changes in PPE as well as trends to expect this year.

NFPA 70E Changes

In the 2015 edition of NFPA 70E, the term “Hazard Risk Category” (HRC) has been replaced by “PPE level” or “arc rated PPE category” (ARC). As a result, manufacturers may start using “ARC” instead of “HRC” on labels to indicate their level of performance in an arc. One PPE manufacturer is also considering using “CAT” (category) with a level. Expect to see more emphasis on the cal/cm² rating in 2015 and less on categories as NFPA, OSHA, NESC and IEEE move toward matching the protection to the hazard and move away from categories of protection. The incident energy that defines the ARC levels will remain the same, but HRC 0 – natural fiber clothing – was eliminated and now PPE is required to be AR.

The NFPA 70E standard also has moved to a more risk-based model that eliminates PPE when there is no risk or an acceptable risk. This is quite difficult to achieve, but when doors are closed, and equipment is properly installed according to the National Electrical Code (NEC), properly maintained according to the manufacturer’s instructions or an applicable standard (NFPA 70B or NETA MTS), and there is no evidence of impending failure, no PPE is required for operation. This is difficult to implement as most companies have limited maintenance programs and utilities typically do not use the NEC for installation. However, using this concept on 240-volt single-phase equipment has been applauded. Most companies will not use this process on three-phase equipment or anything greater than 300 volts due to arc flash energy issues.

New OSHA PPE Requirements

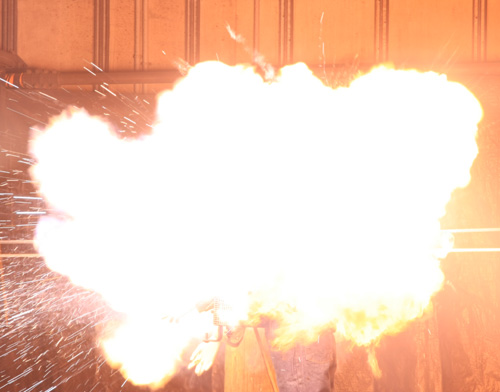

As of December 31, 2014 – barring another delay – OSHA 1910.269 requires that workers with the potential for exposure to an electric arc be provided with AR/flame-resistant (FR) clothing if the incident energy is greater than 2 cal/cm2. While OSHA does not define exactly what “FR” means, it should be understood that all AR clothing is considered to be flame resistant, as the clothing has demonstrated through large-scale testing that it will not ignite or melt and drip in an arc flash. As with the old edition, OSHA prohibits the use of melting materials – such as nylon, polyester and polyethylene – unless these materials are used in blends and have been tested to meet the minimum requirements of ASTM F1506 or ASTM F1891, both of which require arc testing to ASTM F1959. This rule also applies to outerwear and jackets, as OSHA states that the outermost layer must be flame resistant.

There are two standards to watch for when purchasing AR clothing, as cited by NFPA 70E: ASTM F1506 for textile materials and ASTM F1891, which is used for the evaluation of rainwear materials. “Flame resistant” by the OSHA standard, while not defined, does include two stated requirements: (1) must be non-melting and (2) must not ignite in an electric arc exposure. Cotton denim blue jeans do not meet these requirements, so AR shirts, pants and winterwear will be required moving forward.

There are a few reasons why the OSHA standard uses the term FR rather than requiring AR garments. OSHA wants to allow rainwear, winterwear, and high-visibility garments worn for other purposes to avoid layering-protection AR testing as long as they are AR and will not contribute to the injury. This does not mean that common garments claiming FR by NFPA 701 (curtain standard) or ASTM D6413 (vertical flame test that has no pass/fail criteria) are acceptable. These garments, if not AR, will likely melt in arc flash exposures and fail to meet the requirements. AR garments are really required by the OSHA language but do not have to meet the hazard as an individual layer. This avoided the confusion of requiring the outer shell to have all of the protection for the hazard. With the new OSHA language, you can use the winterwear, rainwear, or a coverall as part of the protective system or just think of them as non-contributory and count only the shirt and pant.

Using Layers for More Cost-Effective PPE Compliance

AR flash suits can work for companies, but the total protection level for a utility is easier to comply with by making the common AR shirt and pant part of a system. Using winterwear or rainwear and even an AR T-shirt as part of the system is the best long-term approach. Many companies have used rainwear and winterwear as their switching suits by adding a hood or face shield depending on the protection level. To take advantage of the layering system in your program, check with your rainwear or winterwear provider to see if they have arc-layering data for common shirts used in the industry. Free arc flash data for some common fabric layer systems is available at www.arcwear.com/resources/arc-flash-testing-data.php.

The new OSHA standard also requires that by January 1, 2015, employers must have performed a hazard assessment to estimate the incident energies that employees may be exposed to. Many utilities are lobbying for an extension of this compliance date due to the complexity of this requirement. Training on 1910.269 arc flash assessment will be a hot topic for engineers as companies look to hone their assessments to avoid excessive PPE. In addition, as of April 1, 2015, the employer must provide employees with AR/FR clothing that matches the incident energy of the hazard assessment. This is accomplished by matching the PPE level to the energy that was estimated in the hazard analysis. Again, an AR systems approach with layering data is the most effective way to meet the requirement and keep workers productive in summer months.

Glove, Feet and Face Protection Requirements

As of December 31, 2014, gloves are required when the hazard is above 14 cal/cm2. Heavy-duty work gloves (12 oz.) or rubber gloves with protectors are acceptable to satisfy the OSHA clause for hazards that are estimated to be under 14 cal/cm² (1910.269(l)(8)(v)(A)). It is unclear if rubbers and leather are always acceptable, and the distance the incident energy is calculated for hand protection is also unclear. Removal of leather may also be precluded unless the rubber gloves are assured not to ignite at the calculated level. Arc flash requirements when removing leather protectors are not mentioned in the new OSHA standard, but both leather and rubber or an AR glove is required for hand protection when the 14 cal/cm² threshold is reached.

Feet must be protected and are considered protected by boots or heavy-duty work shoes. The standard does not define these, but NFPA 70E requires leather. Most dielectric shoes have been arc tested to 40 cal/cm², and some non-leather shoes have also been arc tested. Although there is no standard for arc testing shoes, most have used ASTM F2621 for evaluation. We know of no ignition of shoes in arc flash but have seen sock ignitions, mostly in contacts.

At 9 cal/cm2, the head and face must be protected in single-phase arcs in air. For other exposures, 5 cal/cm2 is the requirement. This was a surprise to most of the industry.

New Face Protection Technology

Along with the new requirement for head and face protection in utilities, new technology is available to help employers meet this clause. Lift-front hoods are available from multiple suppliers to provide protection at up to 40 cals, and they offer a higher degree of visibility and venting, as well as a lighter weight.

The lift-front hoods allow the wearer to release body heat and carbon dioxide while taking a breath of fresh air on the job, and they also allow the worker to quickly raise the front for cable/wire color verification. Not only does the hood lift, but some hoods feature a balancing mechanism on top of the head, which allows for a free range of motion with the worker’s hands. This new design effectively builds in a cooling system that does not add to the weight of the product.

Other cooling designs in hoods are also popular and still lightweight. The newer lift-front hoods eliminate fabric on top of the hard hat, making them a better option where overhead shock sources are a risk.

Additional improvements in arc flash face protection include sunglasses and weight-balancing arc flash shields, which balance on the hard hat or retract into it.

New AR sunglasses have been gradually tested and a few companies are expecting to fully rate and provide protection up to 4 cal/cm². Sunglasses tested by ArcWear have typical protection values ranging from 1.5 to 2.7. These are not rated items but can be rated according to ASTM F2178.

ANSI/ISEA 125 PPE Conformity Assessment

With new standards, products and technology coming to the market, it can be difficult to determine what to purchase for your company. In an effort to help suppliers demonstrate their verification of performance, ISEA released a new standard last year: ANSI/ISEA 125 on conformity assessment. Further, end users can use ANSI/ISEA 125 to verify that the PPE they are purchasing will perform as expected.

ANSI/ISEA 125 defines three varying levels of conformity. Level 1 is equivalent to a self-declaration of conformity. Testing can be in-house or out-of-house, and the laboratory that performs the testing does not need to be accredited, nor does the supplier need to be ISO 9001 certified. Level 2 is also a self-declaration, but the supplier must be certified to ISO 9001, and the supplier also must use an ISO 17025-accredited lab for in-house or out-of-house testing. Level 3 is the strictest, requiring full third-party certification of the product.

For all three of the defined levels, ANSI/ISEA 125 requires record-keeping, corrective actions systems, preventive actions, recall procedures, testing to applicable standards at five-year test intervals at minimum and proof of ongoing compliance with the applicable standards. Even conforming to Level 1 will be an improvement for many companies, so ask your supplier about ANSI/ISEA 125 conformance.

Specifying Arc-Rated Clothing

How do you specify garments? As we’ve established, OSHA now requires AR/FR garments for workers with an exposure greater than 2 cal/cm2, as determined through a hazard analysis. Generally speaking, you likely need AR clothing if you use an electrical meter above 240 volts.

Following the hazard analysis, fibers should be considered for the ideal end product. While all fiber content options have pros and cons, it’s important to understand the attributes of different fiber blends as they have a major effect on the properties of the end product. Cottons are known for offering breathability and comfort while being cost-effective, and aramids are known for being thermally stable and typically having a long life. Synthetic fibers are not ideal in situations where molten metal is a hazard; the small amounts of metal in an arc flash are unlikely to be a hazard, but the welding and metals industry should still be concerned about this as a potential hazard. Cotton is not ideal for use around acids or strong bases. Inherent and treated fibers both have a lot to offer, so it’s worth performing the research to determine what fibers will work best for you and your environment.

To be successful in specifying AR garments, make sure that you are purchasing clothing that is labeled as compliant to ASTM F1506-10a, or to ASTM F1891 for rainwear. These are both material tests. You can take it a step further and require that your multilayer garments have been arc tested to ASTM F2621, which is a full garment test. Upon receipt of your garments, inspect them for proper trim and findings, material and labels. Watch out for products labeled as compliant to ASTM D6413 alone (meaningless unless inside of a spec), NFPA 701 (for curtains) and ASTM F1506-98 (before arc testing was established).

Know your manufacturer and consider adding ANSI/ISEA 125 to your specification. Maybe you would like to purchase garments that are third-party certified, which means that the surveillance and spot-checking are covered for you, and the third-party certification logo is placed on the product. Or, you might decide that Level 1 self-declaration is satisfactory. Either way, don’t be afraid to ask the manufacturer for test reports and proof of ongoing compliance. We recommend evaluating the laboratory testing. ANSI/ISEA 125 Level 2 assures that the lab testing is accredited to ISO 17025, which offers a better certainty of lab competence. As the arc market has matured, materials are improving and the increased options make working in AR PPE as comfortable as working in regular work clothing.

About the Authors: Hugh Hoagland of ArcWear and e-Hazard is a specialist in arc flash testing and electrical safety training. Stacy Klausing, M.Sc., of ArcWear is a flame-resistant textile specialist focusing on ASTM F1506 and ASTM F1891 testing.