OSHA and the Host-Contractor Relationship

The revisions to OSHA 29 CFR 1910.269(a)(3) and 1926.950(c) regarding information transfer have brought many changes to the relationship between host and contract employers in the utility industry. As OSHA noted in the preamble to the revised standard, the existing Multi-Employer Citation Policy is insufficient to ensure workplace safety, and hence the agency has implemented a host-contract employer information transfer standard. The following article will shine light on what information must be communicated by which employer as well as how it should be communicated.

Employer Definitions

Before we go any further, it’s important that readers understand what constitutes a host employer and a contract employer.

A host employer operates or controls the operation of transmission and distribution (T&D) or generation facilities on which a contract employer is performing work covered by the OSHA standard. The host employer is typically an electric utility, but if a holding company has outsourced operations control and maintenance to a contractor, then the contractor would be considered the host employer.

A contract employer is an employer other than the host who performs work covered by 1910.269 or 1926 Subpart V under contract with the host employer. This can also include subcontractors who are not under contract with the host, but who are working on the host’s facilities. In either case, in order for the host-contractor information transfer standard to apply, the contractor or subcontractor needs to be performing work covered by the standard. These contractors can include traditional T&D line or underground contractors, contractors working in plants, crane operators or other equipment companies and their employees. The standard also applies to contractors and utility companies who are called upon to assist host companies as part of mutual assistance during major storm outages.

Host Responsibilities

Host employers have a number of responsibilities under the information transfer standard, which are outlined below.

1. The host employer must develop a process to assure that required information is communicated between the host, contractor and subcontractors.

OSHA does not specify how the required communication is to be transferred. The agency notes that there is no requirement for a formal or written report. It is up to the host to put in place a process that effectively transfers information to contractors and subcontractors in a manner that enables the contract employer to pass along the information to its employees and otherwise comply with the standard.

This process consists of two parts. The first part is choosing a means of communication. Telephone, email, text messaging, bid packages, contracts, orientation sessions, websites and maps are among the communication channels that hosts, contractors and subcontractors can use.

Second, host employers must determine the method by which information will be exchanged with contractors and subcontractors. There are three options:

1. The host and contractor/subcontractor can directly exchange information with each other.

2. The host and contractor/subcontractor can exchange information through contacts with whom they do not have contractual relationships.

3. The host employer can establish centralized procedures for contractors and subcontractors to obtain and share required information. Information can be conveyed through such channels as websites, maps, tagging or barricades.

Although it’s not required, the complete communication process should be incorporated in the binding contract between the host and contractor. Contracts for specific projects can include all of the detailed information about the project. Contracts for work activities only (labor units) should include an outline of the process and possibly system characteristics. Additional information, such as known installation conditions, should be transferred on a project-to-project basis.

2. The host employer must provide information to contractors and subcontractors about system characteristics.

The following information is required and should be readily available in T&D environments. In plants, some of the circuit information may be part of the original or modified construction plans.

• Nominal voltage of lines and equipment.

• Max switching-transient voltages per unit (T-factors).

• Hazardous induced voltages.

• Presence of protective grounds and equipment grounding conductors.

• Location of circuits and equipment, including supply, communication and fire protective signaling circuits.

• Other known system information related to safety and requested by the contractor.

3. The host employer must provide information on the known installation conditions.

Under this section, the items to be communicated include but are not limited to:

• The condition of protective grounds or other equipment grounding conductors. This could include whether they are in place and in effect as originally installed.

• The condition of poles.

• Any known environmental conditions related to safety, including water or other environmental hazards in manholes.

If the known installation conditions are not available through reasonable due diligence, it is not necessary for the host to perform an investigation to determine the conditions. The host should notify the contractor regarding the lack of information, and it would then be up to the contractor to perform the appropriate hazard assessments.

4. The host employer must provide additional safety information requested by contractors.

This includes any other information about the design and operation of the host employer’s installation that is known by the host employer, that the contract employer requests and that is related to the protection of the contract employer’s employees.

5. The host employer must provide specific information to the contractor in order for the contractor to develop assessments.

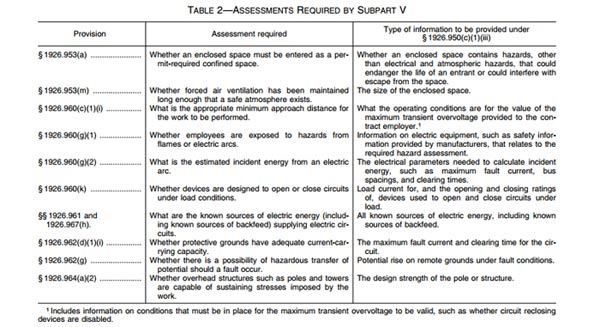

The table below – found on page 20361 of the final rule – shows the assessments that are implicitly or explicitly required by Subpart V and lists information that OSHA anticipates contractors will need to perform the required assessments.

6. The host employer must coordinate the work rules.

OSHA does not require contract employers to follow host employer work rules. However, in some cases, the work rules need to be coordinated. For example, the contract employer should be trained in and follow the host employer’s switching and lockout/tagout procedures.

Contractor Responsibilities

While the host employer certainly bears more of the burden of responsibility with regard to information transfer, contract employers also have several obligations per the OSHA standard, as specified below:

1. The contract employer must advise the host employer of any unique hazardous conditions presented by the contract employer’s work.

During the course of the contract employer’s work, the contractor may produce hazards that could affect the host employer. These hazards can include abnormal switching, temporary work or environmental issues. Once notified by the contract employer, the host employer must communicate relevant information related to these hazards to its employees.

2. The contract employer must provide all transferred information to its employees.

After information has been transferred by the host employer to the contract employer, the contract employer must pass that information along to employees. This usually occurs during pre-job briefings.

3. The contract employer must communicate to the host employer any hazardous conditions that they discover.

Any hazardous conditions that are discovered by the contract employer, and that have not previously been communicated by the host employer, must be communicated to the host within two working days of discovery.

OSHA Enforcement Statement

In a February 2015 memorandum for regional administrators, circulated as part of the recent settlement between OSHA and Edison Electric Institute (see more about the settlement in this issue’s “Train the Trainer 101”), OSHA issued the following statement regarding enforcement of information transfer: “Until June 30, 2015, no citations will be issued to host employers (as defined at 29 CFR 1910.269(x) and 29 CFR 1926.968) under the information-transfer provisions at 29 CFR 1910.269(a)(3) and 29 CFR 1926.950(c), provided that after April 30, 2015, the employer can demonstrate that it is providing contract employers (as defined at 29 CFR 1910.269(x) and 29 CFR 1926.968) with the information, other than information on maximum switching-transient voltages, required by 29 CFR 1910.269(a)(3)(i)(A) and 29 CFR 1926.950(c)(1)(i).”

The memorandum also states that until June 30, 2015, “no citations will be issued to contract employers (as defined at 29 CFR 1910.269(x) and 29 CFR 1926.968) under the information-transfer provisions at 29 CFR 1910.269(a)(3) and 29 CFR 1926.950(c).”

There is much to be aware of with regard to information transfer between host and contract employers. However, if properly implemented, the information exchange processes should significantly enhance hazard identification and overall communication between hosts, contractors, subcontractors and their employees.

About the Author: Ted Granger, CSSBB, CUSP, is the principal consultant for Granger Management Consultants. He provides training, lectures and safety consulting services. Prior to his current role, Granger held various managerial positions during his 37-year career at Florida Power & Light Co. These included T&D operations, human resources, logistics and safety, where he utilized his Six Sigma Black Belt certification. Granger can be reached at tedjgranger@gmail.com.